Description

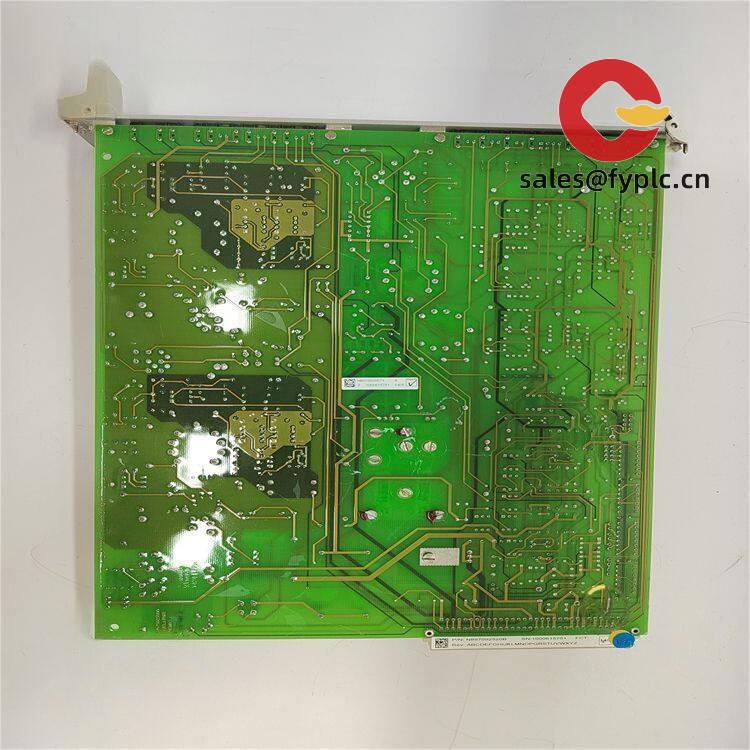

Alstom N897093511D / N897093051D – OEM Rail Control Module for Rolling Stock Electronics

The Alstom N897093511D and N897093051D refer to an original Alstom electronic control module (board-level assembly) used in rolling stock systems—typically within propulsion, braking, or TCMS-related cabinets. In many fleets these two part numbers appear as alternate or successive revisions within the same assembly family, which is why you often see them paired for procurement. From my experience, customers use this as a direct drop-in spare to restore cabinet functionality without requalification.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

One thing I appreciate is how predictable the replacement process is: we match by P/N and revision, function-test prior to shipment, and include a report on request. You might notice that it reduces on-site troubleshooting time, especially when you’re working within tight maintenance windows.

Key Features

- OEM compatibility: Designed for Alstom rolling stock cabinets; supplied to the exact part number (N897093511D / N897093051D).

- Drop-in replacement: Typically plug-in with coded connectors—no harness changes for like-for-like swaps.

- Industrial temperature design: Built for rail environments; stable operation in ventilated control cabinets.

- Signal versatility: Supports mixed digital/analog I/O on the backplane; interface details depend on train platform.

- Service-friendly: Front-access mounting points and labeling help speed up commissioning.

- Traceability: Supplied with part/serial tracking; functional test report available.

- Supporting components available: Backplane connectors, cabinet fan modules, and 24 VDC rail power supplies can be sourced in the same order to simplify maintenance.

Technical Specifications

| Brand / Model | Alstom N897093511D / N897093051D |

| HS Code | 853890 (typical export classification for electronic assemblies) |

| Power Requirements | 24 VDC nominal from cabinet supply (consumption depends on configuration) |

| Dimensions & Weight | Board-level module; standard Alstom rack format; typically under 1.5 kg |

| Operating Temperature | Typically -25°C to +70°C when installed in a ventilated equipment cabinet |

| Signal I/O Types | Mixed digital/analog I/O via backplane and multipin connectors (varies by vehicle platform) |

| Communication Interfaces | Often used with rolling-stock buses such as MVB/CAN/RS-485; check BOM for the specific build |

| Installation Method | Plug-in module for Alstom rack; captive screws or card guides; keyed connectors for orientation |

Application Fields

This module is typically deployed in Alstom rolling stock, including metro cars, commuter EMUs, and mainline vehicles. Common placements include:

- Propulsion or auxiliary converter cabinets as a control/logic board

- Brake control or traction interlock subsystems

- TCMS racks as a functional interface card within the train network

- Depot maintenance replacements for faulted boards to minimize vehicle downtime

A maintenance lead from a metro depot told us it “dropped straight in and cleared the propulsion fault on the next power-up,” which seems to be the norm when the revision matches.

Advantages & Value

- Reliability: OEM hardware with revision matching reduces commissioning risks.

- Compatibility: Like-for-like replacement avoids software changes in most cases.

- Cost control: Prevents prolonged trainset immobilization; fewer rework hours.

- Technical support: Assistance with part identification, cross-reference between N897093511D and N897093051D, and pre-shipment test reports.

Installation & Maintenance

- Environment: Install in a sealed or ventilated control cabinet meeting rail standards; avoid condensation and conductive dust.

- Wiring: De-energize 24 VDC supply before handling. Check backplane connector keys and firmly seat the module; torque captive screws per the cabinet spec.

- Grounding/EMC: Ensure chassis bonding; maintain shield terminations for MVB/CAN/RS-485 cables to minimize noise.

- Safety: ESD protection during handling; allow discharge time for any internal capacitors before removal.

- Routine care: Periodic cabinet cleaning, connector inspection, and firmware/application checks where applicable. Functional verification after overhaul or major software updates is recommended.

Quality & Certifications

- Standards: Built for railway use; typically aligned with EN 50155 and EN 50121-3-2 requirements for rolling stock electronics.

- CE marking: Where applicable for the assembly and its intended market.

- Manufacturing quality: Produced under ISO 9001 quality systems.

- RoHS: Compliance depends on production year and rail exemptions; details available by serial/lot.

- Warranty: 365 days on the supplied unit.

If you can share the train family or cabinet code, we’ll confirm whether N897093511D and N897093051D are interchangeable for your fleet and prepare the matching revision for a straightforward swap.

Reviews

There are no reviews yet.