Description

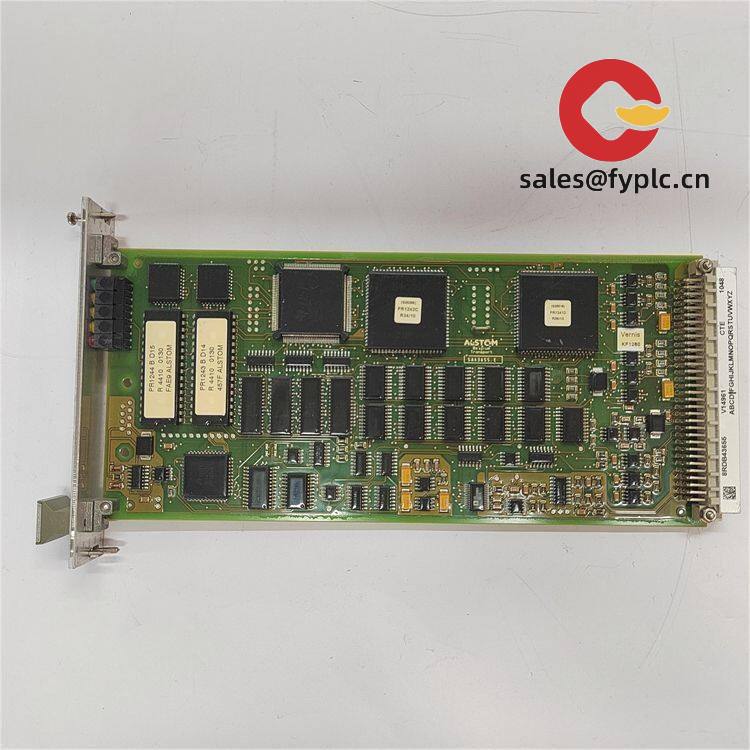

Alstom N897163510Q / N897163050Q – OEM Control Modules for Rolling Stock and Industrial Control Racks

This matched pair—Alstom N897163510Q and N897163050Q—is typically sourced for maintenance and overhaul programs on Alstom traction control, TCMS, and cabinet-based automation systems. From my experience, these two part numbers are often ordered together as companion boards in the same rack position, ensuring firmware and hardware compatibility within the original Alstom backplane. If you’re facing obsolescence or long OEM lead times, this is a practical, factory-spec solution that keeps your fleet or plant running without redesign.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

- Traceability: Serial/lot data and test records provided whenever available

Key Features

- OEM-spec compatibility: Designed for Alstom rack/backplane architectures, reducing integration risk.

- Matched pair procurement: N897163510Q and N897163050Q are commonly installed together to maintain firmware alignment.

- Service-friendly: Supports fast board-level replacement, minimizing downtime during fleet overhauls.

- ESD-safe handling and packing: Each unit is shipped in anti-static, moisture-protected packaging.

- Screened before dispatch: Functional checks and visual inspection performed in most cases; test reports can be shared if required.

- Lifecycle support: Sourcing options for hard-to-find revisions, with guidance on backward/forward compatibility.

Technical Specifications

To avoid assumptions, only confirmed and procurement-relevant details are listed below. Additional specifics can be verified against your equipment code or rack drawing.

| Brand / Model | Alstom N897163510Q and Alstom N897163050Q |

| Product Type | OEM control module pair (plug-in boards for Alstom equipment) |

| HS Code | 853890 (Parts suitable for electrical apparatus of 8535/8536/8537) |

| Installation Method | Plug-in card into OEM backplane/rack; secured with front panel fasteners |

| Intended Environment | Enclosed control cabinet; rolling stock or fixed-install control systems |

| Packaging | ESD/moisture barrier bag, shock-absorbing inner pack |

Application Fields

- Rolling stock control racks (TCMS, propulsion/traction control, auxiliary converters) where Alstom modules are specified.

- Depot test benches and simulators that replicate the original Alstom backplane.

- Wayside or plant cabinets that integrate Alstom subsystems in mixed-vendor environments.

- Spare-part pools for reliability-centered maintenance and rapid fault restoration.

One thing I appreciate is how these modules slot straight into the existing card cage; no rewiring, no firmware juggling if you keep to the recommended pair. A maintenance supervisor recently told me they swapped a failed board in under 30 minutes, got the trainset back on line, and saved a full day of service interruption.

Advantages & Value

- Reliability: OEM-spec hardware helps maintain safety margins and system performance.

- Compatibility first: Firmware and revision checks to align with your rack configuration—reduces nuisance faults.

- Cost and time savings: Faster availability versus redesigning or requalifying alternates; minimized downtime.

- Support: Help with interchangeability, part substitutions, and documentation cross-checks.

Installation & Maintenance

- Cabinet conditions: Install in a clean, ventilated enclosure; avoid condensation and conductive dust. Keep cable routing away from high-EMI sources where possible.

- Power-down policy: Unless the OEM manual explicitly allows hot-swap, de-energize the rack before removal/installation.

- ESD handling: Wear a grounded wrist strap; handle by the front plate and edges, not the components.

- Seating & fasteners: Insert along card guides until fully mated with the backplane; tighten front-panel screws to the recommended torque.

- Routine checks: Visual inspection during scheduled maintenance; verify connector integrity and look for heat discoloration or swollen caps.

- Firmware management: Keep a copy of approved firmware/config; typically, both boards in this pair should remain on matched revisions.

- Cleaning: Use dry, oil-free air at low pressure; avoid solvents unless specified by the OEM.

Supporting Components (Available on Request)

- Card guide and retention kits for Alstom-style rack frames.

- I/O breakout adapters and harnesses (e.g., D-Sub or IDC-to-terminal blocks) sized to your cabinet layout.

- Front-panel covers and EMC gasket sets to maintain shielding and airflow.

- Backplane connector service kits for worn sockets (inspection recommended before replacement).

Quality & Certifications

- Conforms to original Alstom specifications; sourced with traceability whenever possible.

- RoHS alignment is typical for recent revisions; documentation can be shared case by case.

- System-level CE/EN compliance follows the host assembly; these modules are intended for integration by qualified personnel.

- Warranty: 365 days against defects in materials and workmanship.

- Each unit is inspected prior to shipment; functional test reports provided when available.

If you can share your rack designation, equipment code, or current firmware level, we’ll verify interchangeability and line up the correct revision of N897163510Q / N897163050Q before shipping. You might notice that a bit of upfront matching prevents 90% of commissioning hiccups.

Reviews

There are no reviews yet.