Description

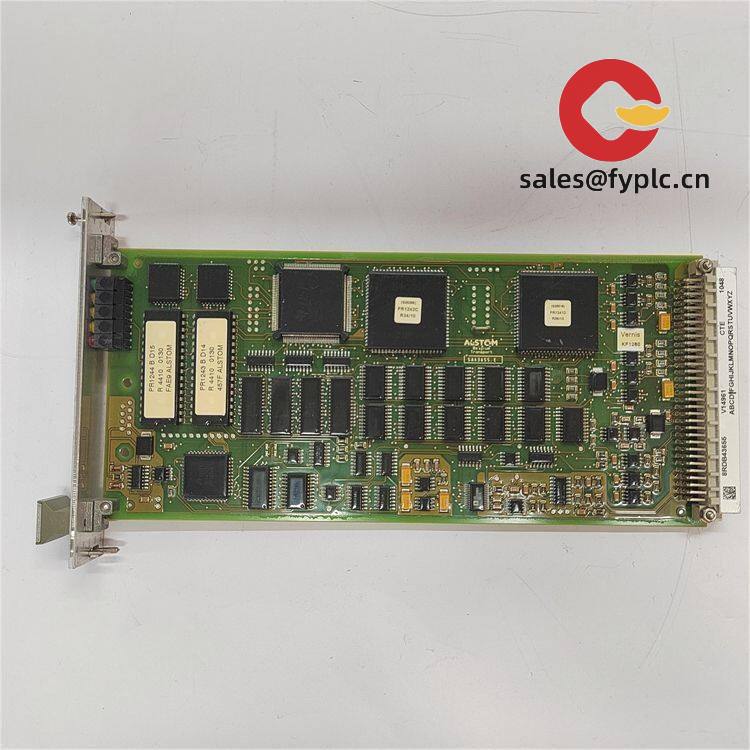

ALSTOM NRD108028-8RDB43655-SA43655 – Plug-in Control/Protection Module for Alstom Industrial & Utility Systems

The ALSTOM NRD108028-8RDB43655-SA43655 is a plug-in module used within Alstom protection and automation platforms, typically as part of a relay or controller rack. From my experience, this type of board is selected to extend core logic, I/O conditioning, or communication functions through the host backplane, keeping wiring tidy and downtime low.

You might notice the build codes “8RDB43655 / SA43655”, which usually indicate a defined hardware variant for a specific rack and firmware pairing.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Backplane-powered design: Draws regulated power from the host chassis; no separate external PSU in most cases.

- Targeted functional role: Typically used for logic/control extension, signal conditioning, or communication bridging within Alstom relay systems.

- Plug-in serviceability: Card-format module enables fast swap during maintenance, helping reduce outage time.

- Host system integration: Interfaces through the Alstom backplane; field I/O and protocols are exposed via the main relay/controller.

- Industrial operating range: Designed for substations and plant rooms, with a pragmatic temperature envelope for control panels.

- Traceable build codes: Variant codes (8RDB43655 / SA43655) support configuration control and replacement matching.

Technical Specifications

| Brand / Model | ALSTOM NRD108028-8RDB43655-SA43655 |

| HS Code | 853890 (Parts suitable for apparatus of 8535/8536/8537) |

| Power Requirements | Supplied via host backplane (typically 5 VDC and/or ±12 VDC rails); no external power input |

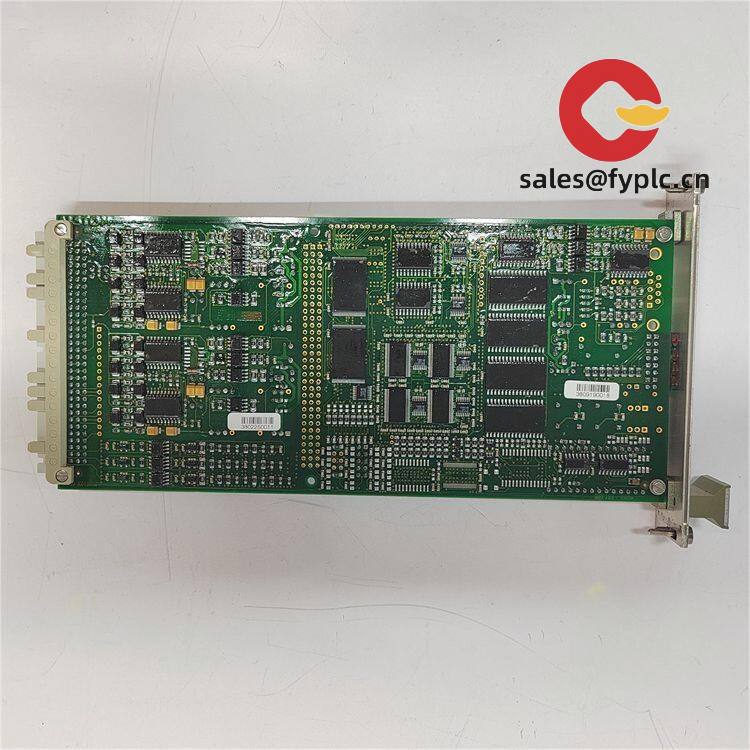

| Dimensions & Weight | Plug-in card format; depth typically 160–220 mm; weight usually ≤ 0.8 kg |

| Operating Temperature | Typically 0 to +55 °C (panel-mounted indoor environments) |

| Signal Input/Output Types | Backplane-interfaced; field signals (digital status, trip/close, analog sensing) are managed via the host relay/controller |

| Communication Interfaces | Through host platform; many Alstom systems support RS‑485/Modbus or Ethernet (e.g., IEC 61850) via the main unit |

| Installation Method | Plug-in module for Alstom rack/chassis; secured with front-panel fixings; connects to system backplane |

Application Fields

This module is typically deployed in:

- Utility substations for feeder, transformer, and busbar protection systems

- Power generation plants (balance of plant control, auxiliary protection)

- Industrial distribution networks and large motor protection panels

- Transport and rail electrification cabinets where Alstom protection platforms are installed

“We swapped in the NRD108028-8RDB43655-SA43655 during a planned outage. It slotted straight into the existing chassis and synced with the relay settings—no field wiring changes, which saved us a service visit.” — Maintenance Supervisor, Combined-Cycle Plant

Advantages & Value

- Compatibility first: Built for Alstom racks, so integration is straightforward and typically does not require panel redesign.

- Reduced downtime: The plug-in format helps speed replacements during outages or predictive maintenance windows.

- Lifecycle continuity: Variant/build codes make matching replacements easier across installed fleets.

- Cost control: Minimizes engineering and commissioning effort because the host system retains wiring and settings.

- Technical support: We can assist with matching firmware revisions and advising on spare-holding strategies for critical feeders.

Installation & Maintenance

- Panel environment: Install in a clean, ventilated control cabinet; maintain ambient typically 0–55 °C with suitable airflow.

- Mounting: Insert straight into the designated slot; ensure backplane connector alignment; fasten front-panel screws evenly.

- Wiring: Field wiring remains on the host relay/controller terminals; verify terminal torque and labeling before re-energization.

- Safety: De-energize the panel, discharge stored energy, and follow site LOTO procedures before handling modules.

- Routine checks: Visually inspect connectors and card edge contacts; clean dust with ESD-safe methods as needed.

- Calibration & firmware: Calibration is generally handled by the host device; confirm firmware compatibility when replacing variant-coded boards.

Quality & Certifications

- Compliance: Products in this family are typically CE compliant; RoHS status depends on build year and variant.

- Quality system: Manufactured under ISO 9001 quality management systems in most cases.

- Warranty: 365-day warranty coverage provided with the supply.

One thing I appreciate is the predictable fit and function—when the variant codes match, commissioning is usually smooth. If you can share the host relay model and slot location, we’ll double-check compatibility and advise on any firmware nuances before shipment.

Reviews

There are no reviews yet.