Description

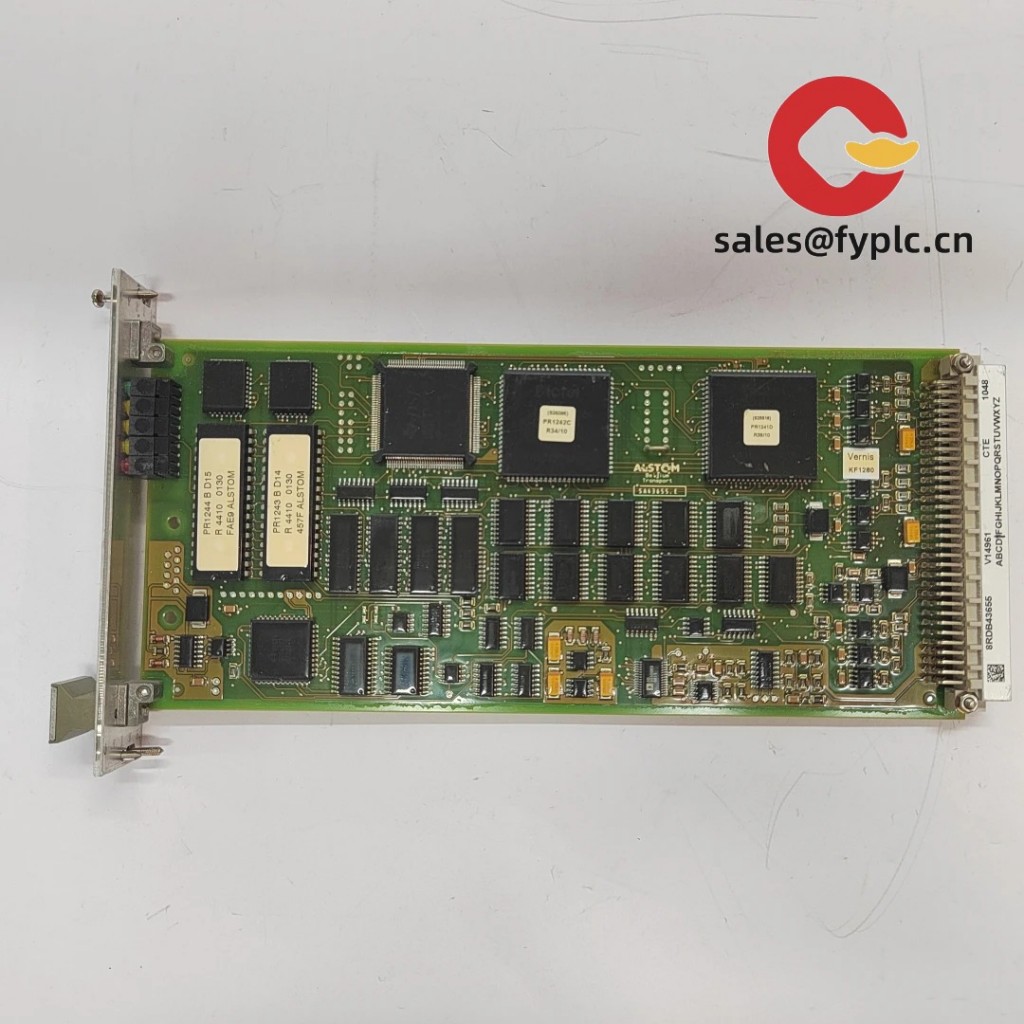

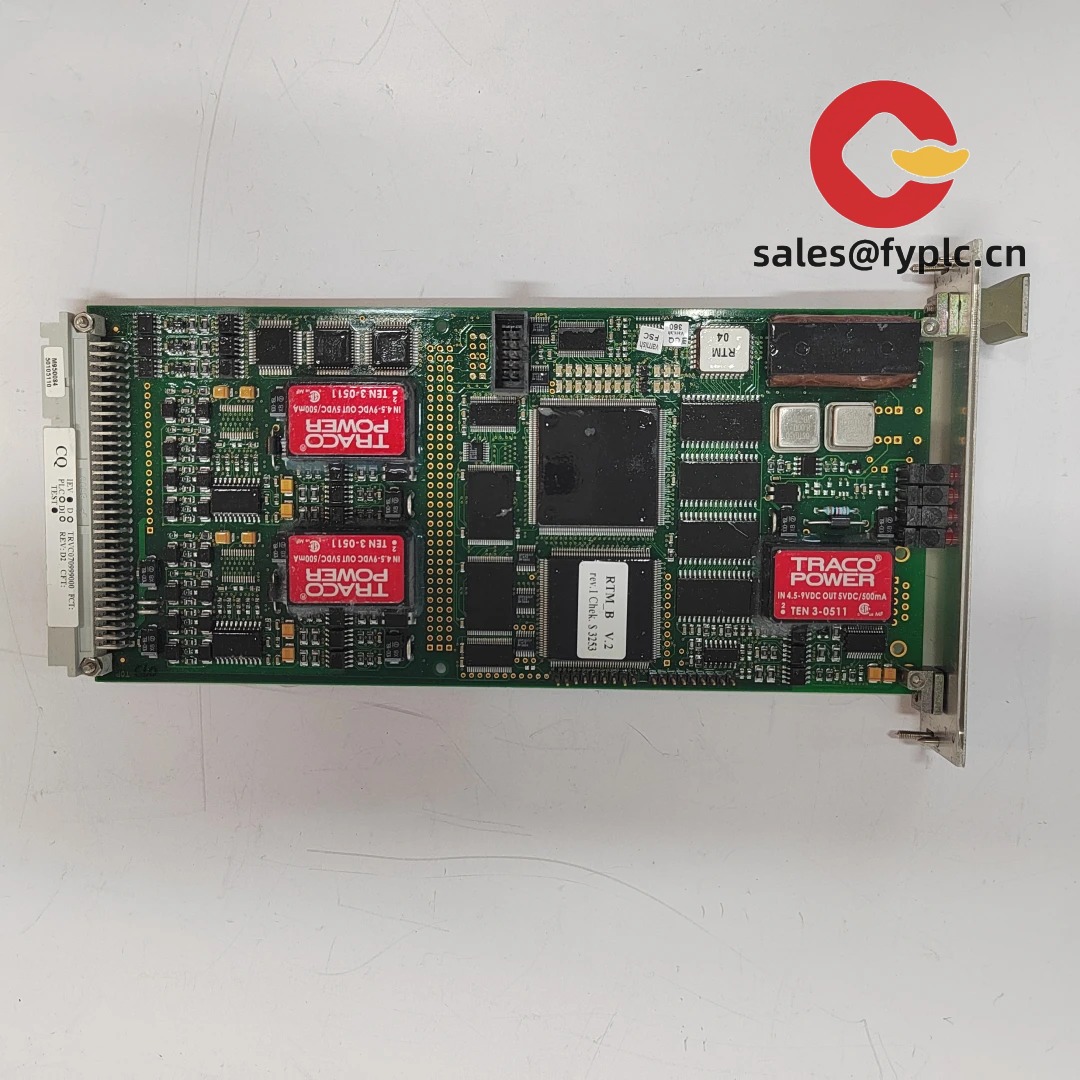

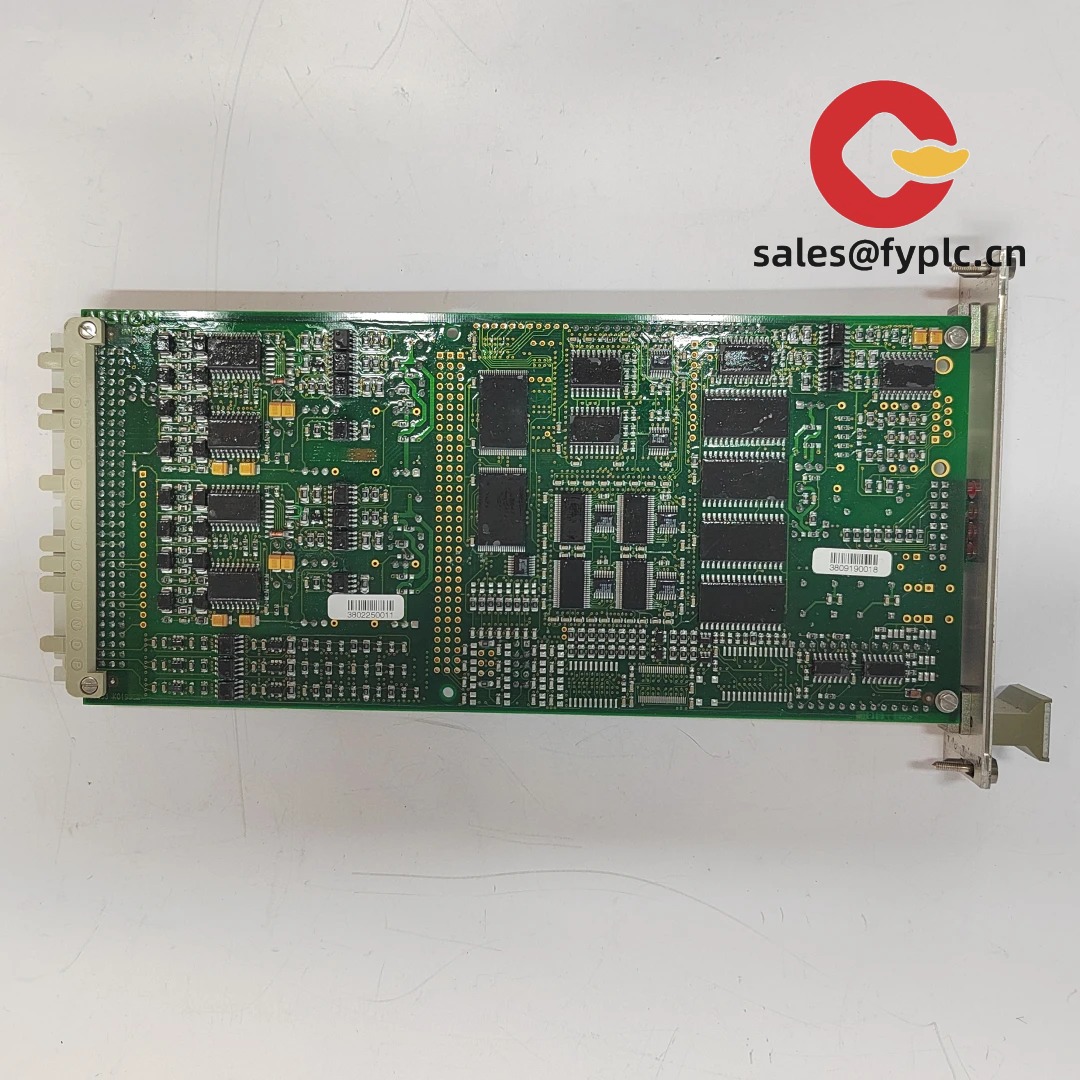

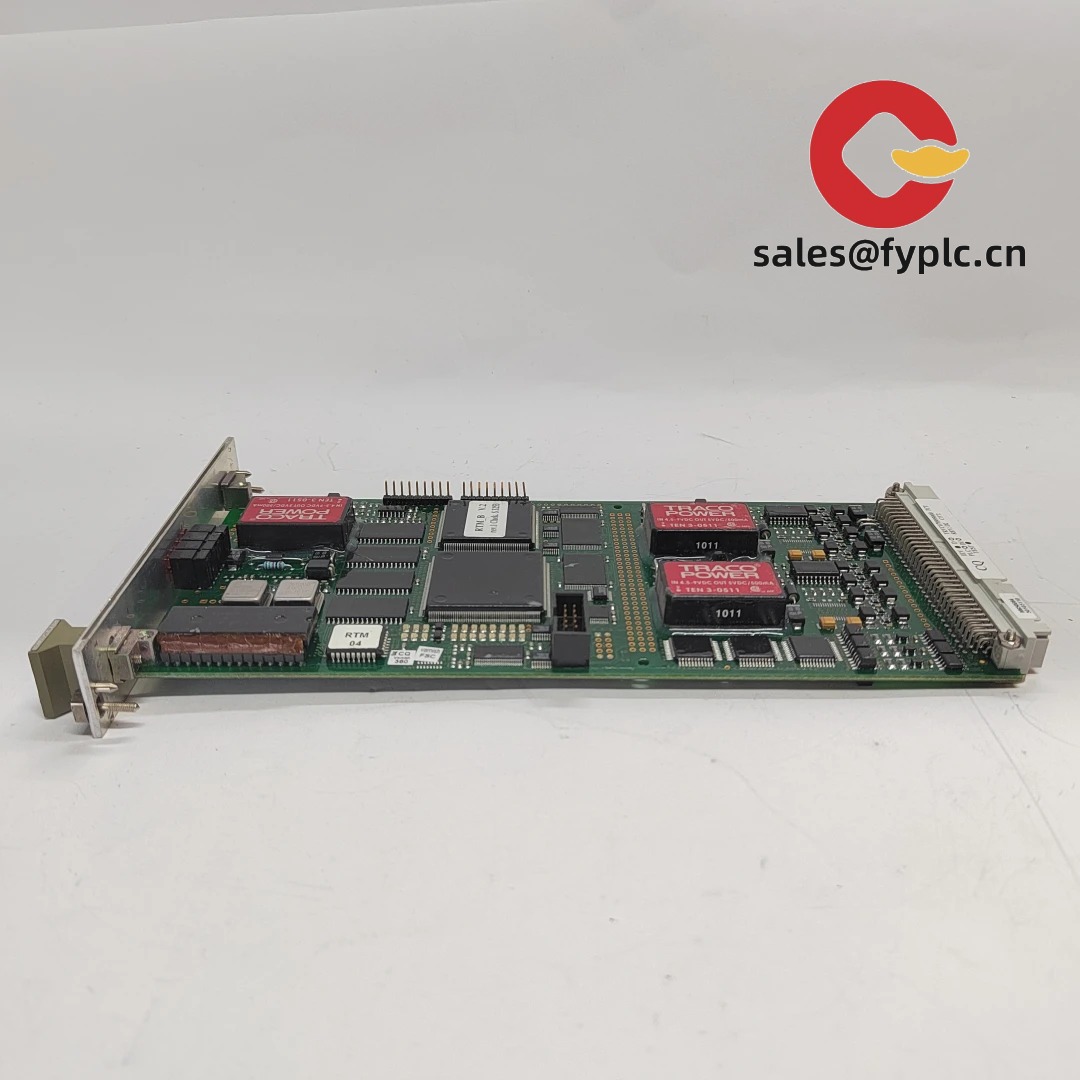

ALSTOM NRD108031 / TRVC070999000 – OEM Control Module for Rolling Stock Cabinets

The ALSTOM NRD108031 / TRVC070999000 is an OEM control module used in train and metro vehicle control cabinets. From my experience with similar ALSTOM assemblies, this unit serves as a form-fit-function replacement in traction or vehicle control systems where reliability and long-term parts support matter more than cutting-edge specs. You might notice that operators typically deploy it as a direct drop-in to restore a down vehicle or to build strategic spares for critical fleets.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: In-stock ships in 1 week; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

- Pre-ship testing: Functional check and visual inspection, with photos/videos on request

- Traceability: Serial number recording and packing list with model details

Key Features

- OEM form-fit-function – Built to slot into existing ALSTOM control racks without cabinet rewiring in most cases.

- Railway-grade construction – Designed for vibration, shock, and electrical noise found in rolling stock environments.

- Service-friendly design – Plug-in card style makes field replacement quick; typically minutes, not hours.

- Stable lifecycle support – Suitable for fleet maintenance programs where consistent revisions reduce integration risk.

- Reliable 24 VDC control integration – Matches common vehicle control bus power, simplifying spares pooling across fleets.

- Documentation support – Build sheets and I/O pinout guidance available on request to speed commissioning.

Technical Specifications

| Brand / Model | ALSTOM NRD108031 / TRVC070999000 |

| Product Type | OEM control module (plug-in card) for rolling stock control cabinets |

| HS Code | 8538.90 – Parts for boards/panels/consoles for electric control or distribution (final classification may depend on end-use) |

| Power Requirements | 24 VDC nominal (typical for vehicle control circuits; verify against unit nameplate) |

| Operating Temperature | Rail-grade range; typically -25 to +70 °C, depending on build and installation location |

| Signal I/O Types | Mixed digital inputs/outputs and possible analog channels; pinout varies by revision |

| Communication Interfaces | Platform-dependent (e.g., MVB, CAN, or RS-485 on certain builds); confirm per S/N |

| Installation Method | Plug-in card into vehicle control cabinet/backplane, typically secured with screws or locking levers |

Application Fields

This module is typically used in electric multiple units, metros, and locomotives as part of the train control and monitoring system. Common roles include handling interlock logic, subsystem supervision, or acting as an interface between sensors/actuators and higher-level vehicle controllers. A maintenance lead from a metro operator told me they keep two units per depot because swap time is short and it immediately clears train unavailability caused by intermittent control faults.

- Control cabinets in traction, braking, or auxiliary systems

- Door, HVAC, or compressor control interfaces (varies by train platform)

- Signal conditioning and I/O aggregation for train management systems

Advantages & Value

- Reduced downtime: Quick plug-in replacement helps restore vehicles fast, which in many cases saves significant crew and slot costs.

- Compatibility: Form-fit with existing ALSTOM racks limits engineering effort and avoids unexpected wiring changes.

- Risk control: OEM-grade build and test reduces the chance of early-life failures in harsh rail environments.

- Support: Access to wiring pinouts, basic installation notes, and post-sale assistance for smoother commissioning.

- Total cost: Stable pricing and a 365-day warranty offer predictable lifecycle planning for fleet managers.

Installation & Maintenance

- Environment: Install in a sealed vehicle control cabinet with adequate ventilation; avoid liquid ingress and conductive dust.

- Power & wiring: De-energize the 24 VDC supply before insertion; observe ESD precautions and cabinet grounding standards.

- Backplane seating: Insert evenly to engage the connector fully; secure with the designated fasteners to withstand vibration.

- Checks: After power-up, verify status indicators and run a simple I/O loop test where applicable.

- Routine care: Periodic connector reseating and cleaning with non-residue agents; review any firmware/config files if the build supports it.

- Spares strategy: Keep at least one tested spare per depot for critical lines—typically pays off during peak service windows.

Quality & Certifications

Documentation for this model can be shared on request. For railway deployments, ALSTOM modules are generally designed with EN 50155 rail environment considerations and materials aligned with EN 45545 fire protection requirements; specific compliance should be confirmed against the exact build code and nameplate. CE conformity documentation is typically available through the OEM channel. Manufacturer quality systems are usually ISO 9001–based.

Suggested Supporting Components

- Backplane/motherboard connectors compatible with the NRD108031 card edge

- Shielded I/O harnesses and labeled terminal blocks for faster fault tracing

- Cabinet vibration dampers and locking hardware for high-shock zones

- 24 VDC filtered power supply module with surge protection (EN rail profile)

Notes: Final part parameters can vary by production run. If you share your unit’s serial/build code, I’ll match pinouts, interface options, and provide the exact datasheet page for your maintenance file.

Reviews

There are no reviews yet.