Description

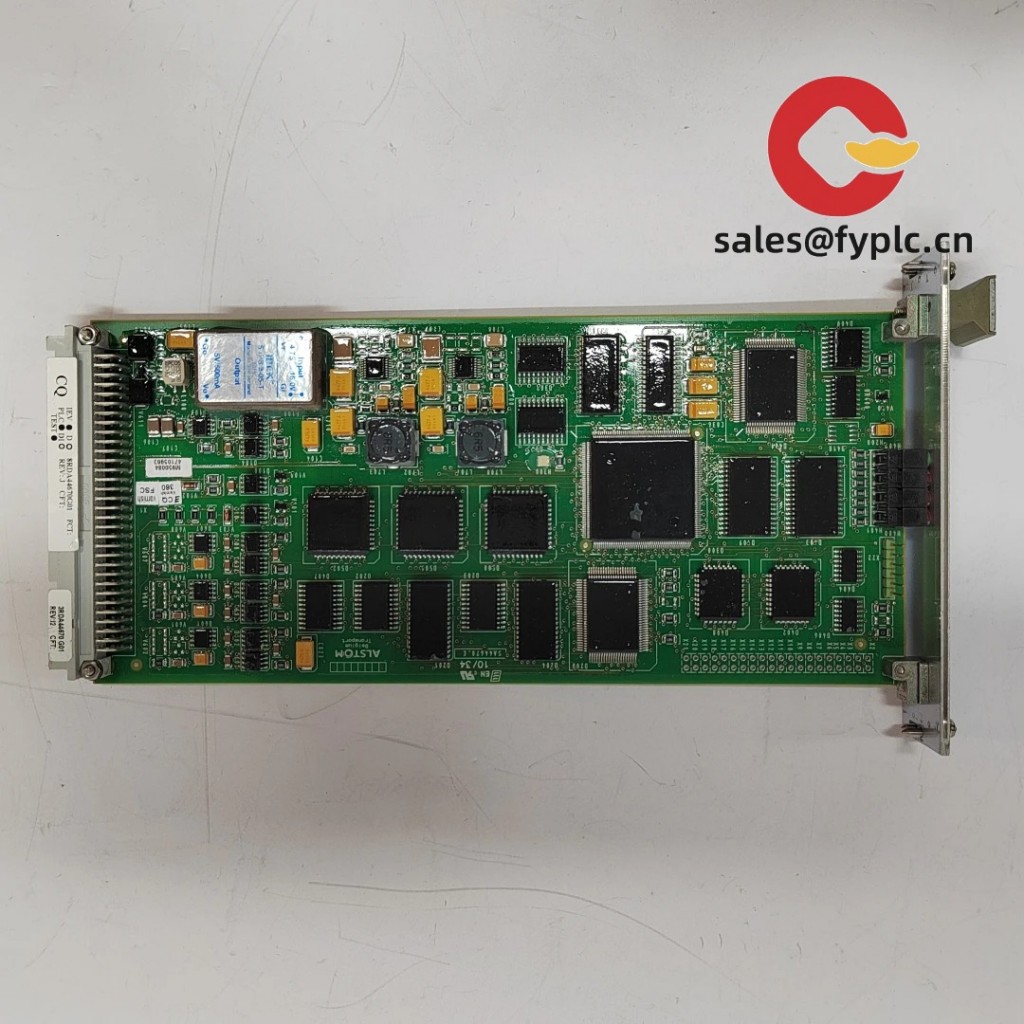

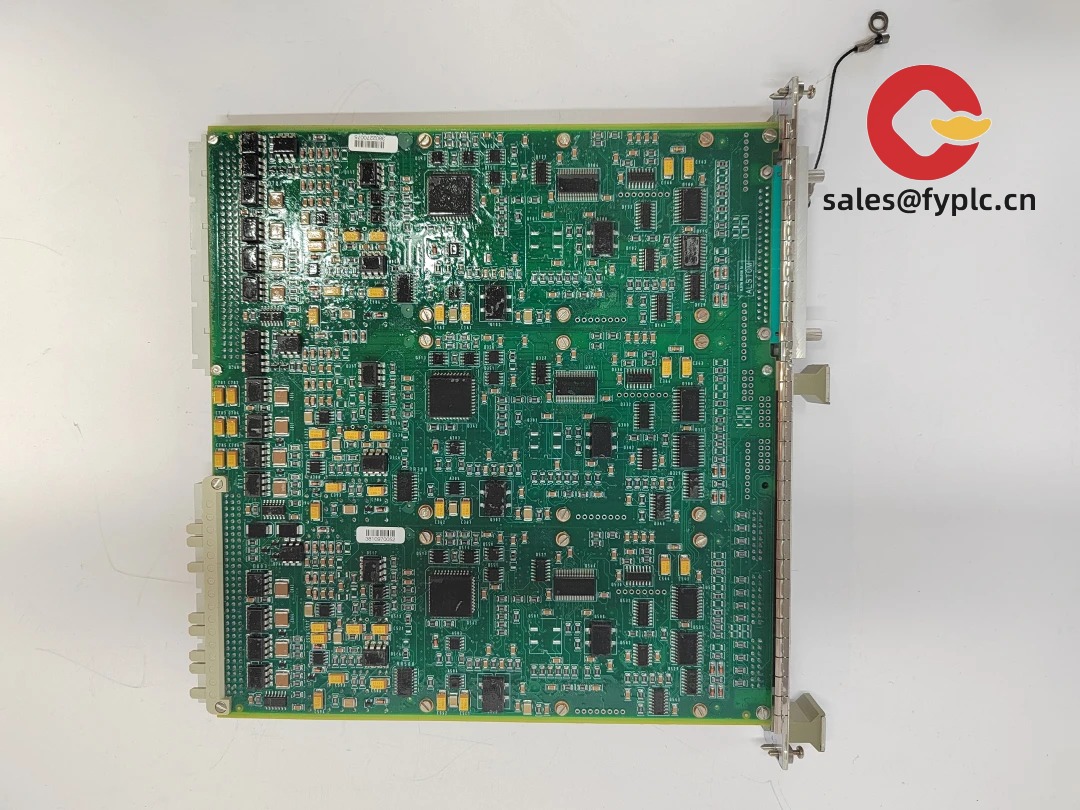

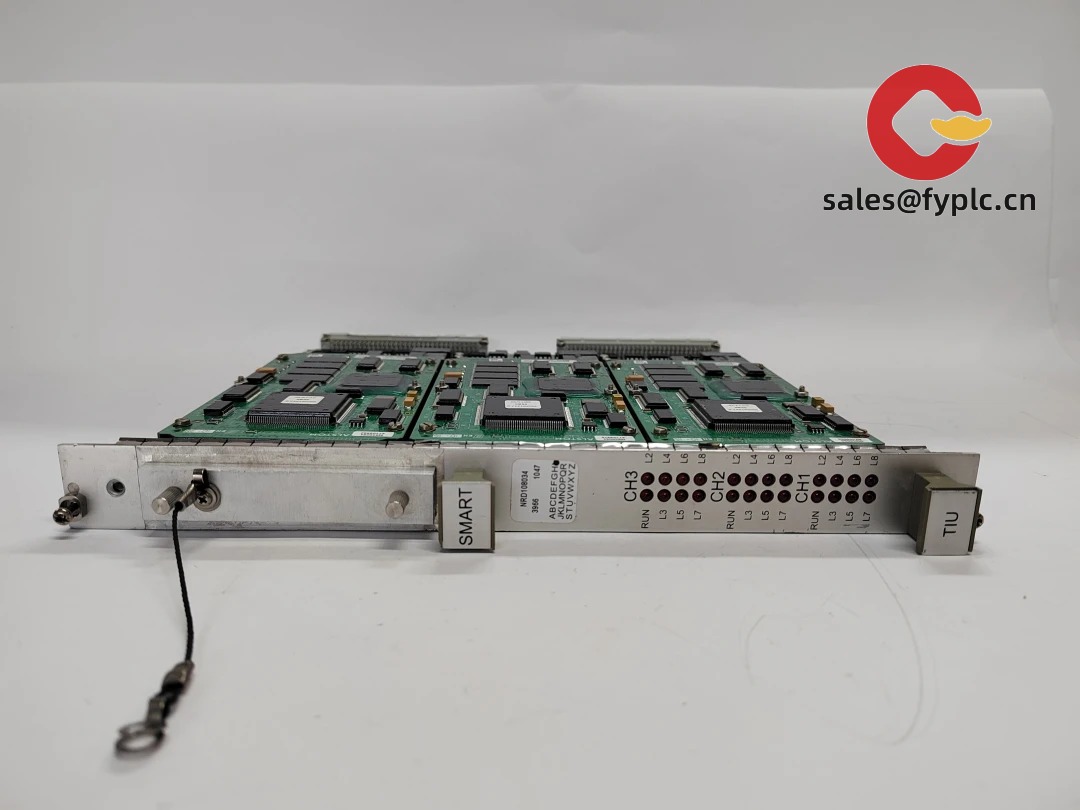

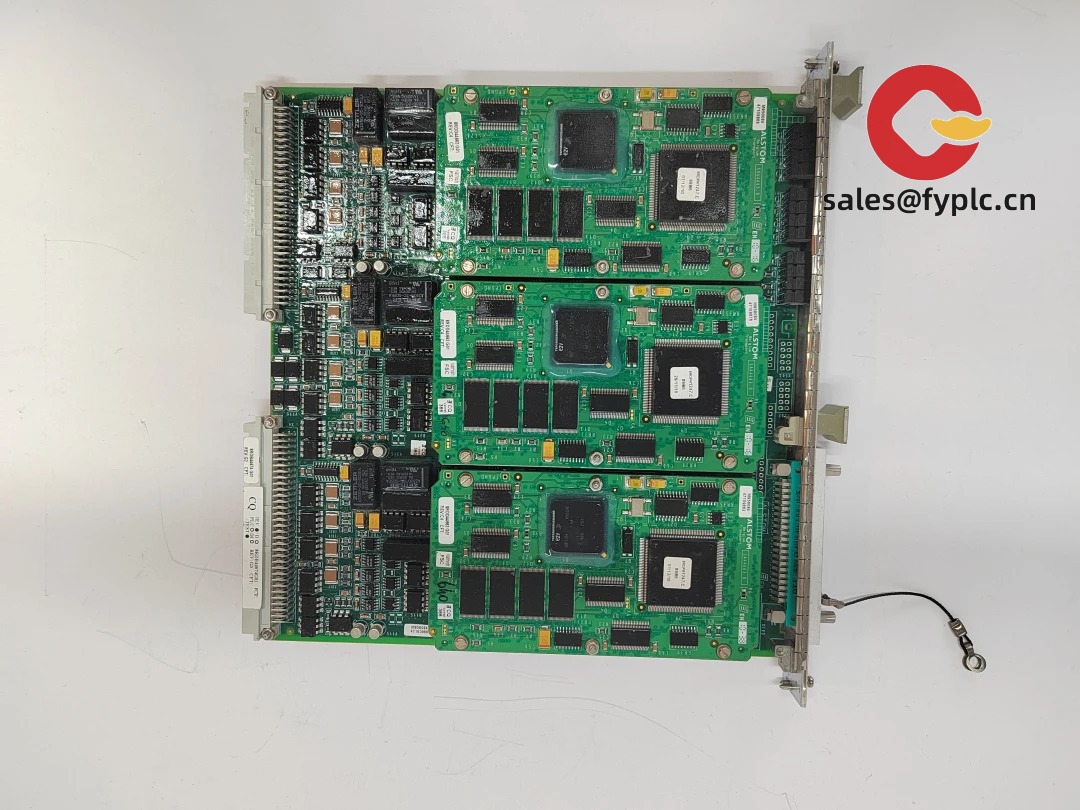

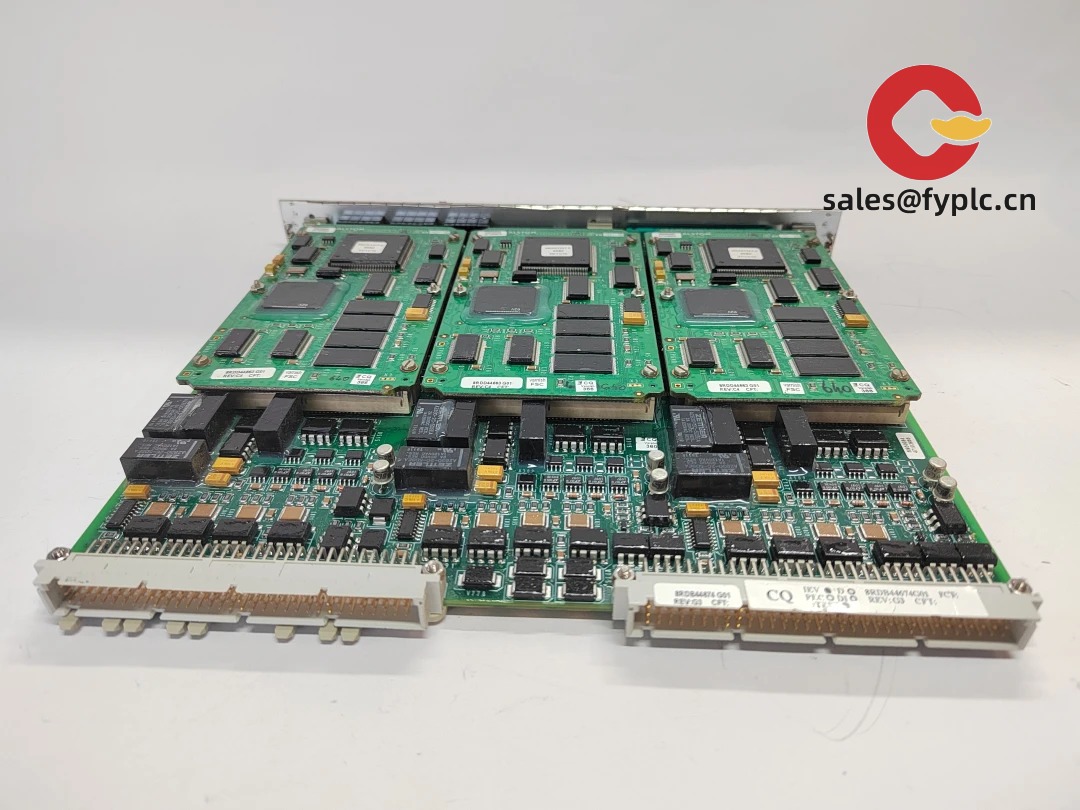

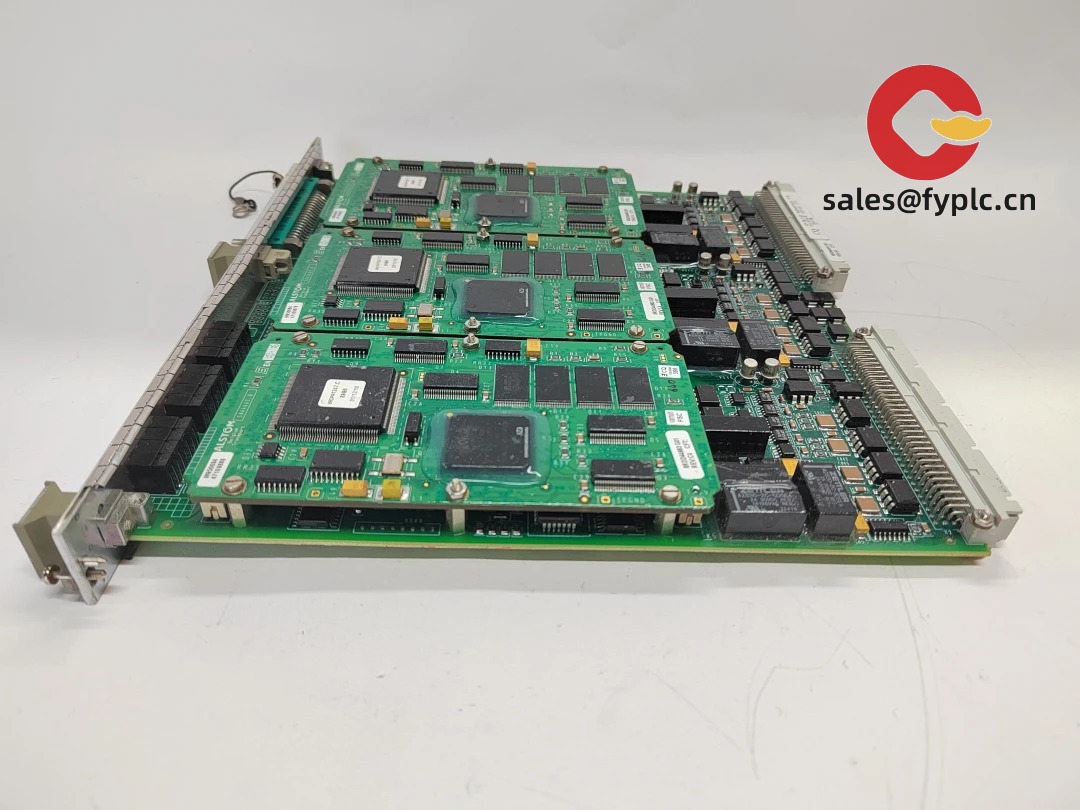

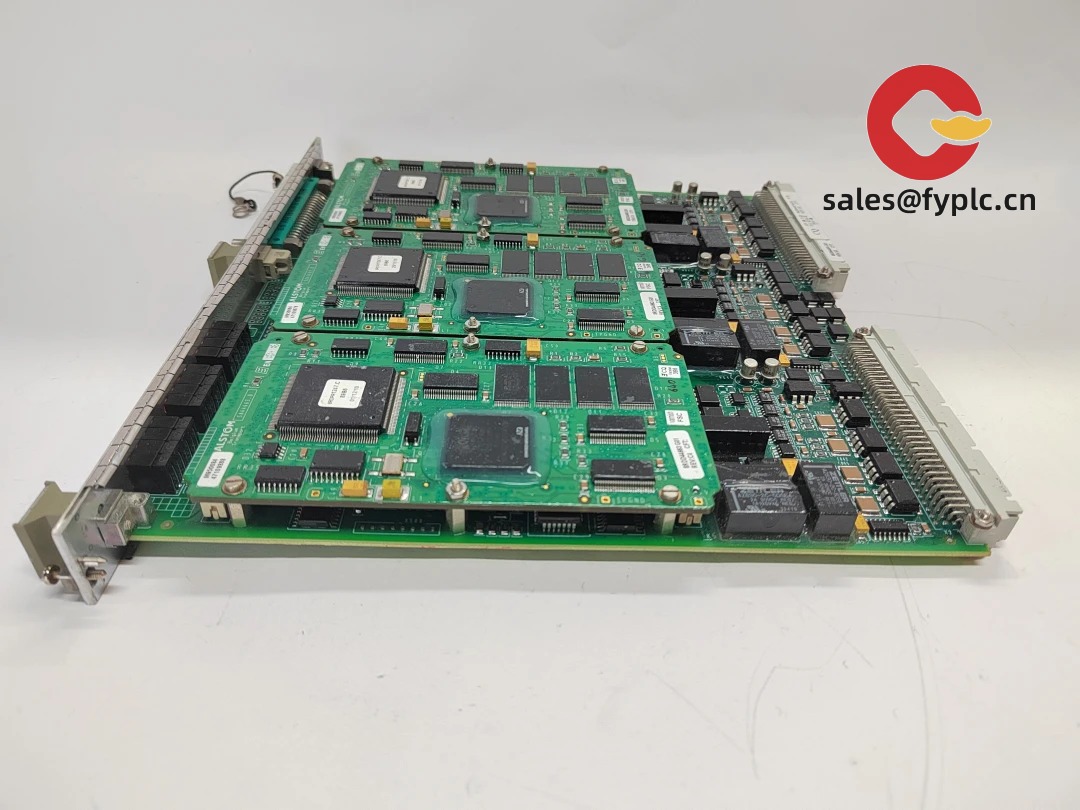

ALSTOM NRD108034 / 8RDB44674G01 / SA44674.C – OEM Plug‑in Control/Protection Board for Legacy ALSTOM Racks

From my experience, this set of ALSTOM identifiers—NRD108034, 8RDB44674G01, and revision SA44674.C—points to an original plug‑in PCB assembly used inside ALSTOM control and protection platforms. It’s typically found as a field‑replaceable module in substations, power generation control cabinets, and similar industrial racks where uptime matters. If you’re maintaining installed ALSTOM equipment and need a reliable, like‑for‑like spare, this model seems to be the safe choice to keep the system running without re‑engineering.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance; full payment before delivery

- Express options: FedEx, UPS, DHL

- Every unit is functionally tested prior to dispatch, and packaging is anti‑static with shock protection.

Key Features

- OEM Compatibility – Built for ALSTOM racks; drop‑in replacement for the NRD108034 assembly family (8RDB44674G01, rev. SA44674.C).

- Backplane Integration – Interfaces through the system backplane; no re‑wiring of field terminals in most cases.

- Industrial‑grade Components – Designed for continuous operation in control rooms and substations.

- Service Life Extension – A practical way to sustain legacy ALSTOM installations without a full upgrade project.

- Traceable Revision – SA44674.C revision alignment helps match installed base configurations and spares lists.

- Quality Screening – Units are inspected and electrically verified before shipment; test reports available on request.

Technical Specifications

| Brand / Model | ALSTOM NRD108034 / 8RDB44674G01 (Rev. SA44674.C) |

| Product Type | Plug‑in control/protection PCB assembly (rack module) |

| HS Code | 8538.90 (Parts suitable for apparatus of headings 8535/8536/8537) |

| Power Requirements | Backplane‑supplied from host chassis; typically uses logic rails (e.g., 5 VDC and auxiliary rails as defined by the host) |

| Operating Temperature | 0 to +55 °C typical, non‑condensing (aligns with standard control room conditions) |

| Signal I/O Types | Backplane digital/analog signaling as per ALSTOM rack specification; no user field terminals on the module faceplate |

| Communication Interfaces | Internal backplane interface; no external Ethernet/serial port on module front (typical) |

| Installation Method | Plug‑in card for ALSTOM rack; insert along guides and secure via front fasteners |

Application Fields

You might notice that this module shows up most in power and transportation environments where ALSTOM platforms are standard. Typical uses include:

- Substation protection and control systems (legacy ALSTOM racks)

- Power plant auxiliary control cabinets and excitation/logic panels

- Industrial MV/LV switchgear protection logic

- Rail traction power protection and depot control panels (where ALSTOM hardware is installed)

A maintenance superintendent told us this board “dropped in with no wiring changes” and brought a relay bay back online within an afternoon—exactly the kind of minimal‑disruption fix teams want.

Advantages & Value

- Risk Reduction – OEM form/fit/function helps avoid nuisance trips and unexpected firmware mismatches.

- Cost Control – Extends the life of installed assets; typically far cheaper than fast‑tracking a platform upgrade.

- Short Downtime – Plug‑in replacement keeps outage windows tight and predictable.

- Supportable – We provide test data and revision verification, which simplifies your QA and stores acceptance.

Installation & Maintenance

- Cabinet Requirements – Install in the designated ALSTOM rack slot; ensure clean, ventilated control‑room environment and stable power rails.

- Handling – Observe ESD precautions; use the module handles and avoid touching components or edge fingers.

- Wiring – No field wiring changes in most cases; all connections are via the backplane connector.

- Commissioning – After insertion, perform system self‑tests and verify status LEDs/indicators according to the host manual.

- Routine Care – Annual inspection recommended: check seating and fasteners, clean dust with dry air, and review firmware/logic in the host system if applicable.

Quality & Certifications

- Certifications – Typically CE compliant when installed within the certified host system; RoHS status may vary by production date; UL/CSA compliance follows the complete rack assembly.

- Quality System – Supplied under ISO‑aligned QA processes with functional testing prior to shipment.

- Warranty – 365‑day warranty; replacement or repair support if a functional defect is confirmed.

Supporting Components (on request)

We can also help with matching faceplates, card guides, backplane connectors, and compatible ALSTOM rack accessories if you’re standardizing spares across multiple bays. It usually saves time during outages to kit these together.

Reviews

There are no reviews yet.