Description

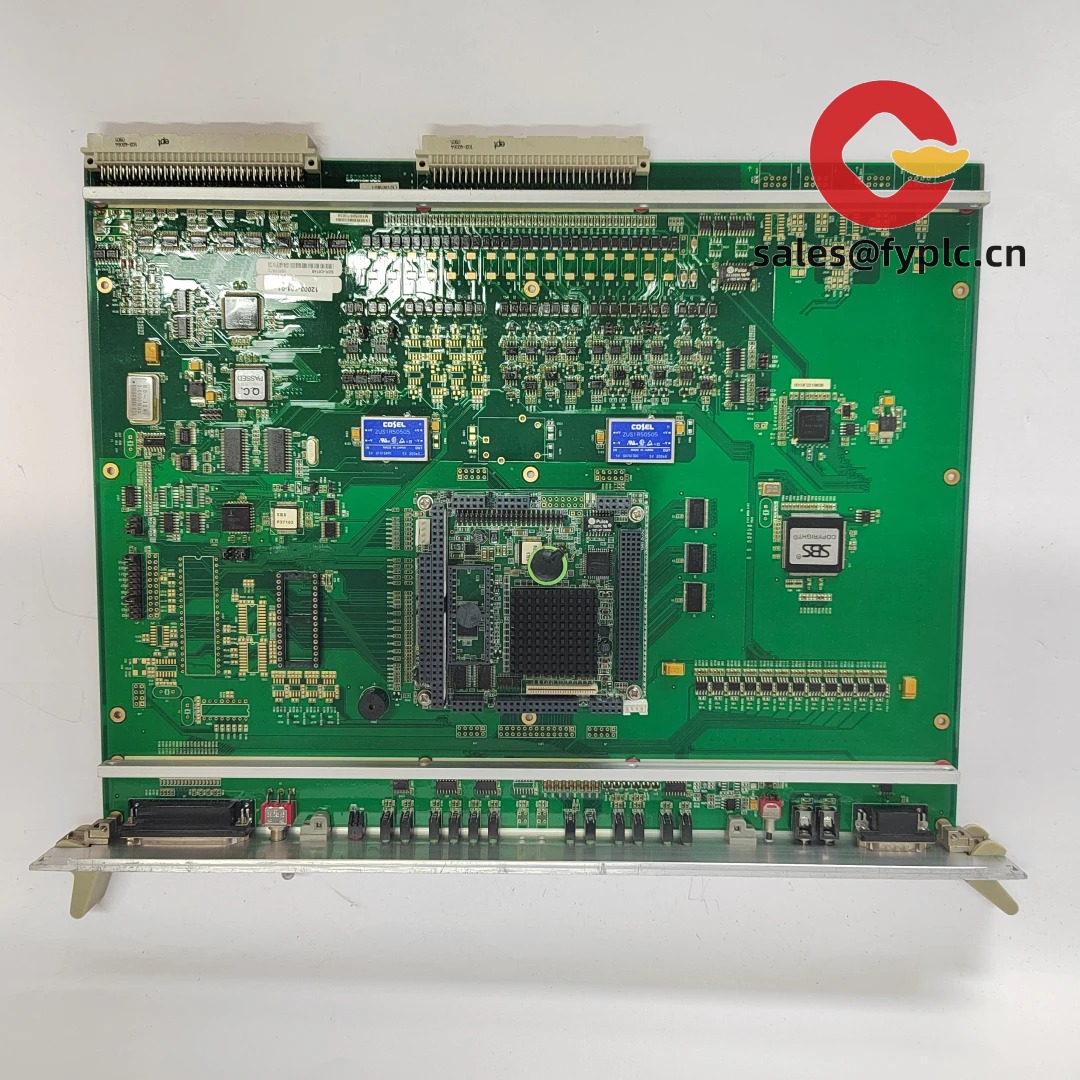

ALSTOM SDK-C0148 12003-101-01 (SBS05M09B) – Plug‑in Control Board for Rail and Industrial Automation Racks

The ALSTOM SDK-C0148 12003-101-01, revision code SBS05M09B, is a plug‑in control/IO board designed for Alstom rack-based systems used in rail traction, wayside signaling, and other heavy‑duty industrial controls. From my experience, this type of module typically handles deterministic backplane communication, health monitoring, and conditioned IO, acting as a reliable intermediary between the host controller and field devices. You might notice that Alstom boards like this prioritize robust construction, long service life, and dependable supply continuity—key factors for maintenance teams working under tight operating windows.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full balance before delivery

- Express delivery: FedEx, UPS, DHL

- Packaging & handling: ESD-safe packing, moisture barrier bag where applicable, shock‑absorbing outer carton

- Traceability: Lot/serial recording and outbound test report available on request

Key Features

- Rack plug‑in design – Slides into an Alstom host chassis backplane for quick swap‑out and minimized downtime.

- Backplane-powered – Draws low‑voltage DC from the system backplane, simplifying field wiring.

- Industrial durability – Board construction and components selected for vibration and extended service; conformal coating is commonly present on rail variants.

- Deterministic signaling – Optimized for stable communication with controller CPUs and IO carriers in safety‑relevant cabinets.

- Lifecycle continuity – Suitable as a like‑for‑like maintenance spare in existing ALSTOM installations, helping reduce requalification effort.

- Front‑accessible service – Plug‑in removal from the cabinet front enables fast diagnostics and replacement under time pressure.

Technical Specifications

| Brand / Model | ALSTOM SDK-C0148 12003-101-01 (SBS05M09B) |

| HS Code | 853890 (Parts suitable for electrical apparatus of 8535/8536/8537) |

| Power Requirements | Backplane supply from host chassis (low‑voltage DC; typical of Alstom rack systems) |

| Signal I/O Types | Digital control and status via system backplane; faceplate connectors if populated |

| Communication Interfaces | Proprietary Alstom backplane interface (module‑to‑CPU/IO bus) |

| Installation Method | Plug‑in PCB for Alstom rack/cabinet; front‑insert with retention hardware |

Application Fields

This module is commonly used in:

- Rolling stock control cabinets (traction control, auxiliary converter supervision)

- Wayside signaling racks and interlocking cabinets

- Rail traction substations and SCADA interface panels

- Heavy industrial automation where Alstom rack systems are deployed

One thing I appreciate is how it slots into existing cabinets without rework. A maintenance lead told us they swapped this board during a night shift and had the line back in service within an hour—no wiring changes, just reseat and verify status LEDs.

Advantages & Value

- Reliability under vibration – Built for rail/industrial environments; typically shows stable performance over long duty cycles.

- Form/fit compatibility – Like‑for‑like replacement reduces engineering change and validation costs.

- Cost savings – Avoids cabinet redesign; shortens downtime windows and technician hours.

- Technical support – We can share handling notes, backplane pinout guidance (as available), and outbound test results to speed commissioning.

Installation & Maintenance

- Cabinet standards – Install in the designated Alstom rack slot; ensure mating connectors are clean and undamaged.

- Ventilation – Maintain cabinet airflow; keep filters clean to avoid localized hot spots.

- Wiring – Use the existing backplane; if front connectors are present, verify keying and torque to manufacturer guidance.

- Safety – Isolate power, discharge stored energy, and follow ESD procedures (grounding strap, ESD mat).

- Routine checks – Visual inspection for oxidation or cracked solder joints; reseat during scheduled outages if intermittent contacts are suspected.

- Firmware/config – If the board carries programmable content, back up parameters prior to swap and verify revision alignment with the host CPU.

- Cleaning – Dry, oil‑free compressed air; avoid solvents on conformal‑coated surfaces.

Quality & Certifications

- Manufacturer quality systems typically align with ISO-based processes for railway/industrial products.

- CE conformity and RoHS status can be provided by revision/lot where applicable.

- Functional test report and warranty: 365 days from shipment.

Related Supporting Components

If you are planning a maintenance window, consider stocking the associated host chassis power supply, the backplane connector kit, and spare front panel fixing hardware. These small items, in many cases, make the difference between a 20‑minute swap and a prolonged outage.

Reviews

There are no reviews yet.