Description

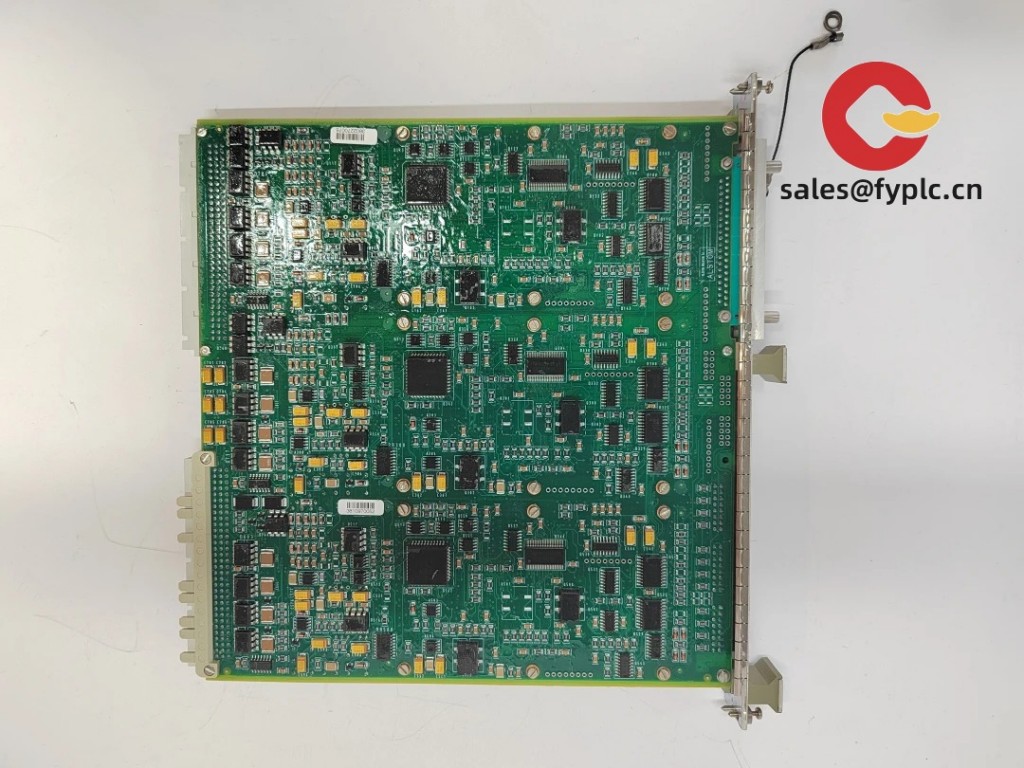

ALSTOM STO1726KO1 – Industrial Control Board for Drive/Protection Interlocks

The ALSTOM STO1726KO1 (often written as STO1726K01) is a plug‑in control board used in ALSTOM/Converteam drive and protection assemblies, typically tied to stop/interlock chains or safety-related signal conditioning inside medium-voltage and high‑power drive systems. From my experience, this module shows up in retrofit and maintenance projects where keeping legacy ALSTOM drives running reliably is the priority, and it seems to be favored because it drops in without PLC or wiring changes. You might notice that it’s designed for backplane power and quick swap-outs, which in many cases keeps downtime to a minimum during a planned stop.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Drop‑in replacement for ALSTOM platforms – Typically installs without rewiring; designed for the original rack/backplane.

- Backplane‑powered design – No external power feed; simplifies service and reduces wiring faults.

- Interlock/safety signal handling – Commonly used in stop chains, permissive logic, and torque inhibiting paths in drive cabinets.

- Rugged industrial build – Components and layout aimed at stable operation in plant environments with electrical noise.

- Service-friendly – Quick card extraction and reseat for troubleshooting; supports rapid MRO workflows.

- Proven field reliability – In many cases, runs for years with minimal adjustment once commissioned.

Technical Specifications

| Brand / Model | ALSTOM STO1726KO1 |

| HS Code | 8538.90 (Parts suitable for electrical control panels/apparatus) |

| Power Requirements | Backplane supplied, low‑voltage logic power (no external feed required) |

| Operating Temperature | Typical industrial ambient 0–55°C (application dependent) |

| Signal Input/Output Types | Discrete logic and interlock signals; opto‑isolated paths are commonly used in this series |

| Communication Interfaces | Not a fieldbus device; interfaces via the host backplane and hardwired I/O |

| Installation Method | Plug‑in PCB card for ALSTOM rack/backplane, front service access |

Application Fields

You’ll typically find the STO1726KO1 in medium‑voltage drives and high‑power motion systems where reliable stop/permissive logic matters. Common deployments include:

- Steel and metals rolling lines (line drives, coilers, and auxiliary motors)

- Power generation auxiliaries and excitation-related cabinets

- Oil & gas compressors and pump trains using ALSTOM/Converteam drives

- Marine propulsion and thruster control cabinets

- Test benches and large industrial OEM machinery retrofits

Advantages & Value

- Continuity with existing systems – Keeps legacy ALSTOM platforms running without PLC requalification, which in many cases saves weeks of engineering.

- Lower risk commissioning – Backplane pinout and logic behavior match the installed base, reducing unexpected interlock trips.

- Downtime reduction – Card‑level swap means faster MTTR; maintenance teams can validate with simple interlock tests.

- Cost control – More economical than a full drive upgrade while preserving safety/permissive functionality.

- Technical support – Guidance on compatibility and pre‑ship testing helps avoid second visits onsite.

A maintenance engineer from a metals plant shared that swapping to an STO1726KO1 restored a stubborn permissive chain in under an hour—no PLC edits, just reseat, verify LEDs, and re‑energize. That’s typically what teams want on a Friday night call‑out.

Installation & Maintenance

- Cabinet & environment – Install in a clean, dry control cabinet (IP54 or better is common). Maintain clearance for airflow and avoid mounting near high‑heat sources.

- ESD and handling – Use ESD protection; handle by edges. Inspect the edge connector and backplane fingers for debris before insertion.

- Wiring & interlocks – Verify all hardwired permissives and safety loops are de‑energized before work. Label and check any terminal blocks associated with the interlock chain.

- Commissioning checks – After seating the board, run the standard interlock test routine: permissive chain continuity, emergency stop validation, and safe torque inhibit verification.

- Routine maintenance – Quarterly visual inspection for discoloration or loosened card guides; light dust removal with dry, oil‑free air; tighten ground points. Firmware updates are typically not applicable to this card type.

Safety note: lock‑out/tag‑out procedures should be followed. For MV drives, discharge confirmation and cabinet earth verification are essential prior to card handling.

Quality & Certifications

- Quality control – Each unit is inspected and electrically tested prior to shipment.

- Certifications – Typically supplied as part of CE‑marked drive systems; RoHS/UL status can vary by production batch and era. Documentation can be provided case‑by‑case.

- Warranty – 365‑day warranty coverage.

Ordering Support

To help verify fit and compatibility, share the host drive model, cabinet tag, and any nearby card part numbers. If your documentation lists STO1726K01 or STO1726KO1, we can cross‑check revisions against your installed backplane before shipping. Lead times are kept tight—1 week when in stock, and not more than one month latest.

Reviews

There are no reviews yet.