Description

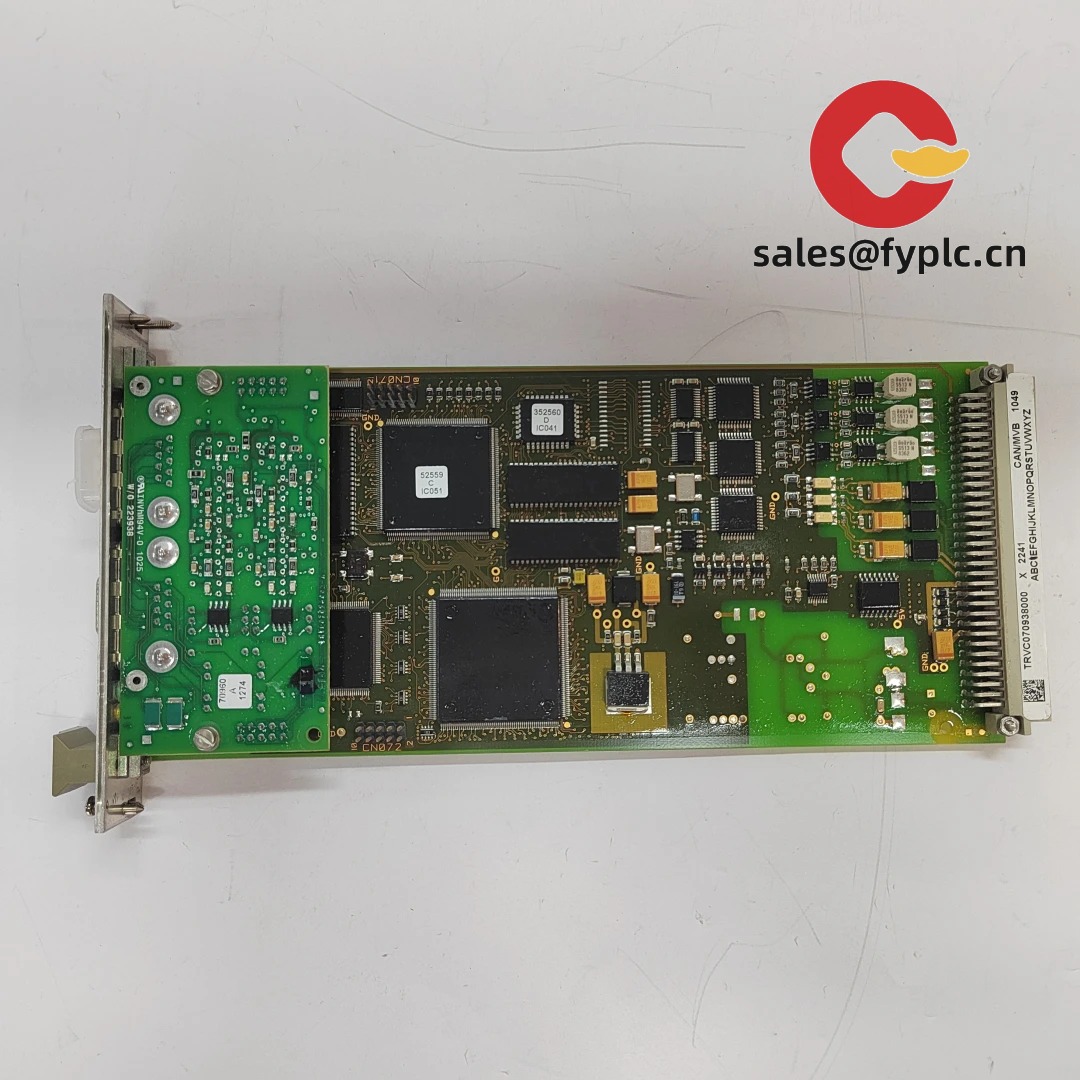

ALSTOM TRVC062105000 / TRVC070938000 / TRVC070938005.A – TRVC-Series Control Modules for Railway and Industrial Control Racks

The ALSTOM TRVC-series modules (models TRVC062105000, TRVC070938000, and TRVC070938005.A) are plug-in control/monitor boards designed for ALSTOM rack systems typically used in rolling stock propulsion cabinets, auxiliary converter panels, and related control assemblies. From my experience, these TRVC boards are selected as like-for-like replacements to shorten downtime and maintain OEM behavior without re-qualifying the cabinet. If you’re maintaining mixed fleets or legacy cabinets, having all three variants on hand helps address slight firmware or hardware revisions found across vehicles and years.

Our Order Placement Process and Guarantees

-

- – Warranty period: 365 days from delivery for quality-related issues

-

- – Delivery time: in-stock units ship in about 1 week; not more than 1 month at the latest

-

- – Payment terms: 50% advance payment; full balance prior to delivery

- – Express options: FedEx, UPS, DHL (we ship with tracking and protective packing)

Key Features

- TRVC-family compatibility – Designed to slot into ALSTOM control racks; typically no panel rewiring or re-engineering.

- Fast swap for reduced downtime – Field teams can replace a board within minutes in most cabinets, then verify via standard commissioning checks.

- Stable I/O through backplane – Signals route via the edge connector/backplane, keeping front panels clean and minimizing cable handling.

- Lifecycle support – We source multiple TRVC variants (e.g., TRVC070938005.A) for fleets where revisions matter to software interlocks or diagnostics.

- Documentable traceability – Units supplied with serial and revision data; test reports available when specified on order.

- Stocking strategy for rail depots – You can standardize spares per trainset or per cabinet type; seems to be the easiest way to keep KPIs on-time.

Technical Specifications

| Brand / Model | ALSTOM – TRVC062105000 / TRVC070938000 / TRVC070938005.A |

| HS Code (reference) | 8538.90 – Parts suitable for electrical control or distribution apparatus |

| Power Requirements | Supplied via host rack backplane; typically 24 VDC nominal in many ALSTOM control cabinets |

| Form Factor | Plug-in PCB module with front panel; installs in ALSTOM rack guides and edge connector |

| Signal I/O | Mixed analog/digital signals through backplane; no field terminals on the board front in most cases |

| Communication | Backplane bus interface (model-dependent logic handled by the host system) |

| Operating Temperature | Commonly engineered for railway environments; −25 °C to +70 °C is typical for similar modules |

| Installation Method | Slide-in replacement; secure front panel screws; powered by the cabinet backplane supply |

| Dimensions & Weight | Compact rack module; typically under 1 kg; outline drawing available on request |

Application Fields

These TRVC modules are usually found in:

- Rolling stock propulsion cabinets (traction converters, auxiliary converters)

- Onboard control racks for EMU/DMU/metro vehicles where ALSTOM architectures are installed

- Depot maintenance benches for board-level testing and fault isolation

- Industrial control panels utilizing ALSTOM rack standards in brownfield upgrades

One operator told us their maintenance window is tight: swapping a TRVC070938000 brought an auxiliary converter back online within the same night shift—no cabinet rewiring, just a functional check and restart.

Advantages & Value

- Reliability – Direct-fit replacement reduces integration risk and preserves OEM logic.

- Compatibility – Multiple TRVC part numbers cover fleet variations; helpful when vehicles carry different software baselines.

- Lead-time savings – In-stock options typically ship in a week, which in many cases beats factory queues.

- Traceable supply – Serial tracking and test reports available to support audits and safety cases.

- Technical support – We can assist with cross-referencing board revisions and recommending safe swap procedures.

Installation & Maintenance

- Cabinet environment – Use a clean, ventilated rack enclosure; keep ambient within the rolling stock spec. Avoid condensation during cold starts.

- ESD and handling – Handle boards with ESD protection; isolate vehicle power and discharge DC links before removal/installation.

- Wiring – No field wiring on the board front in most cases; verify correct seating in the backplane connector and tighten panel screws.

- Commissioning – After replacement, run the cabinet’s self-tests and confirm interlocks, I/O status, and diagnostics on the HMI.

- Routine care – Periodically clean rack filters, check connector retention, and document firmware/application versions if applicable. Keep one spare per fleet subset for resilience.

Quality & Certifications

- Designed and supplied under ISO 9001 quality management frameworks

- CE marking where applicable to subsystem integration

- Railway practices typically aligned with EN 50155 (electronic equipment on rolling stock) and EN 50121 (EMC) — model-specific documentation can be provided

- RoHS compliance may depend on legacy build and exemptions; confirm per batch

- Manufacturer’s warranty support: 365 days (see terms above)

Related and Supporting Components

- ALSTOM-compatible rack guides and edge connectors (replacement guide rails, front-panel screws)

- 24 VDC regulated power supplies for test benches and depot diagnostics

- Backplane extenders for safe live measurements during troubleshooting

- Harness adapters and labeling kits to standardize cabinets across fleets

One thing I appreciate is how consistent the TRVC-series feels across revisions. You might notice small part number changes—often they’re about firmware or component updates—so matching the suffix (like “TRVC070938005.A”) to your vehicle list typically avoids nuisance faults.

Reviews

There are no reviews yet.