Description

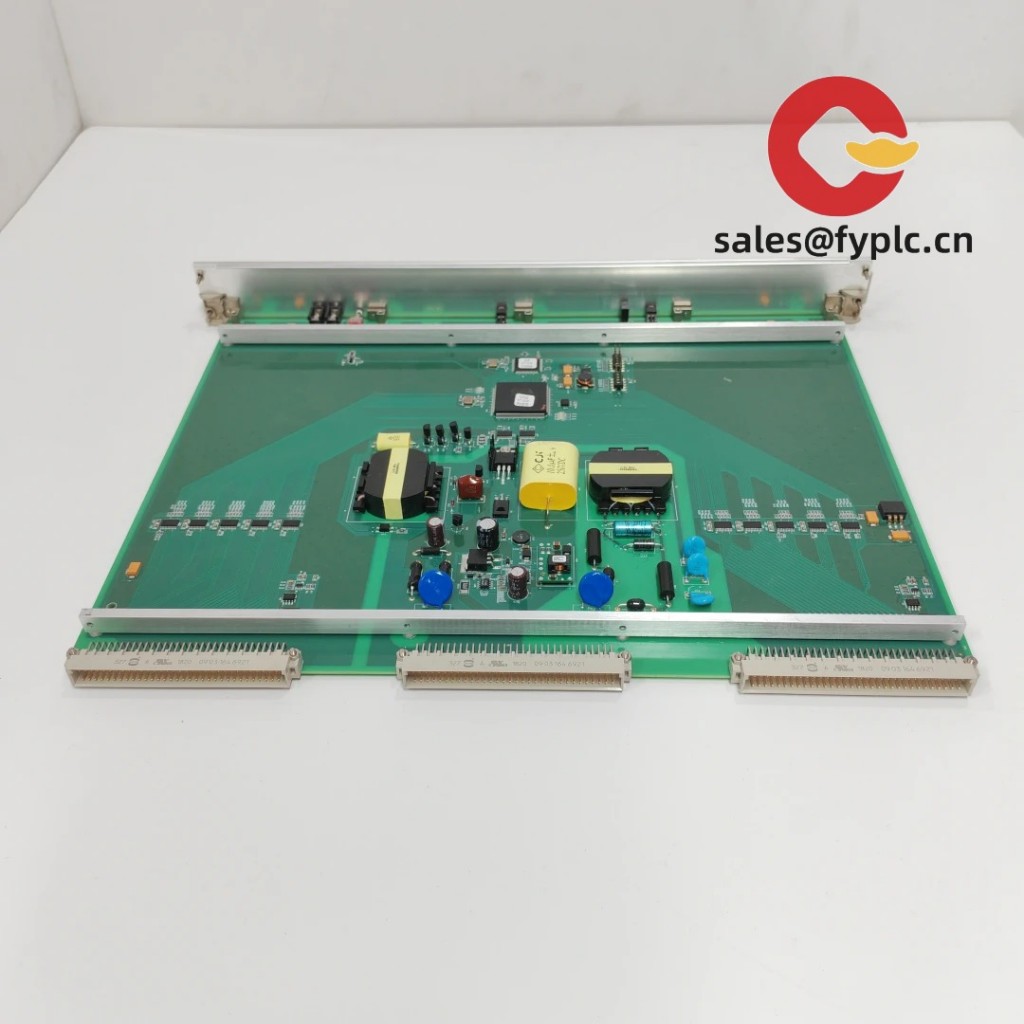

Applied Materials AMAT 0010-23716 – OEM Spare Part for Semiconductor Process Tools

AMAT 0010-23716 is an original Applied Materials spare part used on mainstream AMAT wafer-processing platforms. From my experience, this part is typically specified as a direct, drop-in replacement within OEM service manuals, making tool recovery and uptime much smoother. If you’re trying to solve an unexpected downtime event or planning preventive maintenance, this unit fits well into standard fab practices: traceable, ESD-safe packaged, and ready for cleanroom handling.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

One thing I appreciate is how quickly we can confirm revision compatibility. Share your tool type, chamber, and the current part label (including rev/ECO if available), and we’ll verify interchangeability before you commit.

Key Features

- OEM authenticity – Supplied as an Applied Materials-original spare for reliable fit and performance.

- Drop-in replacement – Designed to match the original mounting and connectors, so swap-outs are typically quick.

- Traceability – Lot and serial tracking available for fab documentation and audits.

- Cleanroom-ready packaging – ESD-safe materials and protective wrapping to prevent contamination during transfer.

- Flexible supply options – New or refurbished (when available), with functional testing reports upon request.

- Supportive documentation – We can align with your PM kit, BOM, or ECO notes to minimize configuration mismatches.

Technical Specifications

| Brand / Model | Applied Materials (AMAT) / 0010-23716 |

| HS Code | 8486.90 – Parts for machines and apparatus for manufacturing semiconductor devices |

| Part Category | OEM spare assembly (tool-specific function; confirm per tool/chamber and revision) |

| Power Requirements | Not applicable or varies by assembly; follows original AMAT specification |

| Signal I/O / Interfaces | Tool-specific; supplied as per OEM connectors and pinout for the designated module |

| Installation Method | Direct replacement per AMAT service manual; observe ESD and cleanroom handling procedures |

| Operating Environment | Typical fab ambient: 15–30°C, non‑condensing; ISO cleanroom handling recommended |

| Condition Options | New or professionally refurbished (subject to availability); test reports available on request |

| Packaging | ESD-safe, clean bagging, and protective cushioning; labeled for traceability |

Application Fields

This part is used across AMAT semiconductor process equipment—commonly in deposition, etch, metrology, or transfer modules depending on the tool build. You might notice that many fabs keep one or two on the shelf to support PM windows and to reduce MTTR on unplanned events. It seems to be a practical way to guard line capacity when cycle times are tight.

- Front-end wafer processing tools (typical AMAT platforms)

- Module-level spares for chamber or transfer subsystems

- Use in corrective maintenance, PM kits, and ECO-driven replacements

Advantages & Value

- Reliability – OEM form/fit/function reduces integration risk and repeat failures.

- Compatibility assurance – We cross-check part labels (rev/ECO) against your tool BOM before shipping.

- Cost control – Refurb options and exchange programs available in many cases, which typically lower total cost.

- Faster recovery – Stocked items can ship within a week via expedited couriers.

- Technical support – Installation guidance, torque notes, and ESD handling tips shared upon request.

Installation & Maintenance

- Follow AMAT service documentation; isolate power and apply lockout/tagout before removal or install.

- Use ESD protection (wrist strap, mat) and cleanroom gloves; keep the part bagged until point-of-use.

- Inspect connectors, seals, and mounting points for wear or contamination; replace any damaged hardware.

- Torque fasteners to OEM spec; avoid over-tightening that can stress boards or brackets.

- Document the swap (serial/lot, date, chamber ID) to maintain traceability and support future troubleshooting.

- For electronics, consider keeping firmware/config backups if the sub-assembly requires parameterization.

Quality & Certifications

- Manufactured under OEM quality systems (typically ISO 9001 at the facility level)

- RoHS/CE/UL applicability depends on the specific sub-assembly; compliance documents can be provided when available

- Warranty: 365 days from shipment against defects in materials and workmanship

Supporting Components We Can Supply

To simplify maintenance windows, we can bundle typical companion items—mounting hardware, connector backshells, replacement seals/gaskets, ESD-safe covers, and cable harnesses matched to your tool revision. In many cases, customers also request chamber O-rings or alignment pins to complete the PM scope with a single shipment.

From a recent customer note: “We swapped 0010-23716 during a PM and cut our restart time by about 40 minutes. Having the right rev on hand made the difference.” If you share a photo of your current part label, we can validate compatibility the same day.

Reviews

There are no reviews yet.