Description

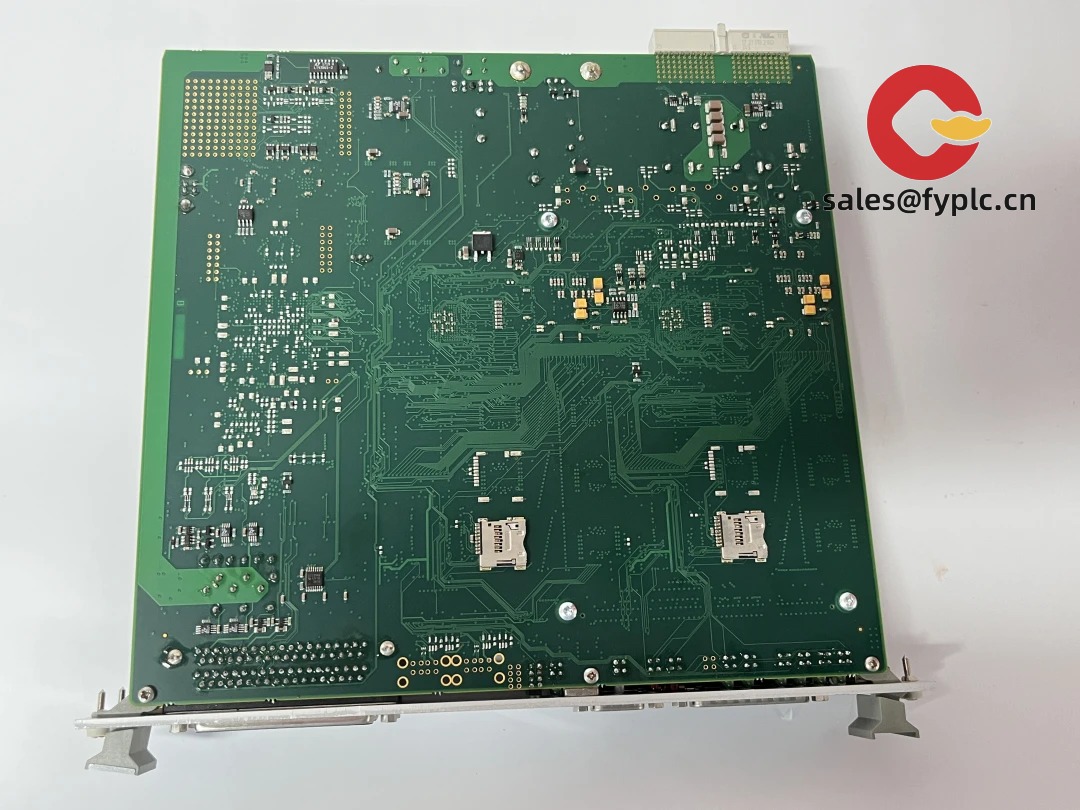

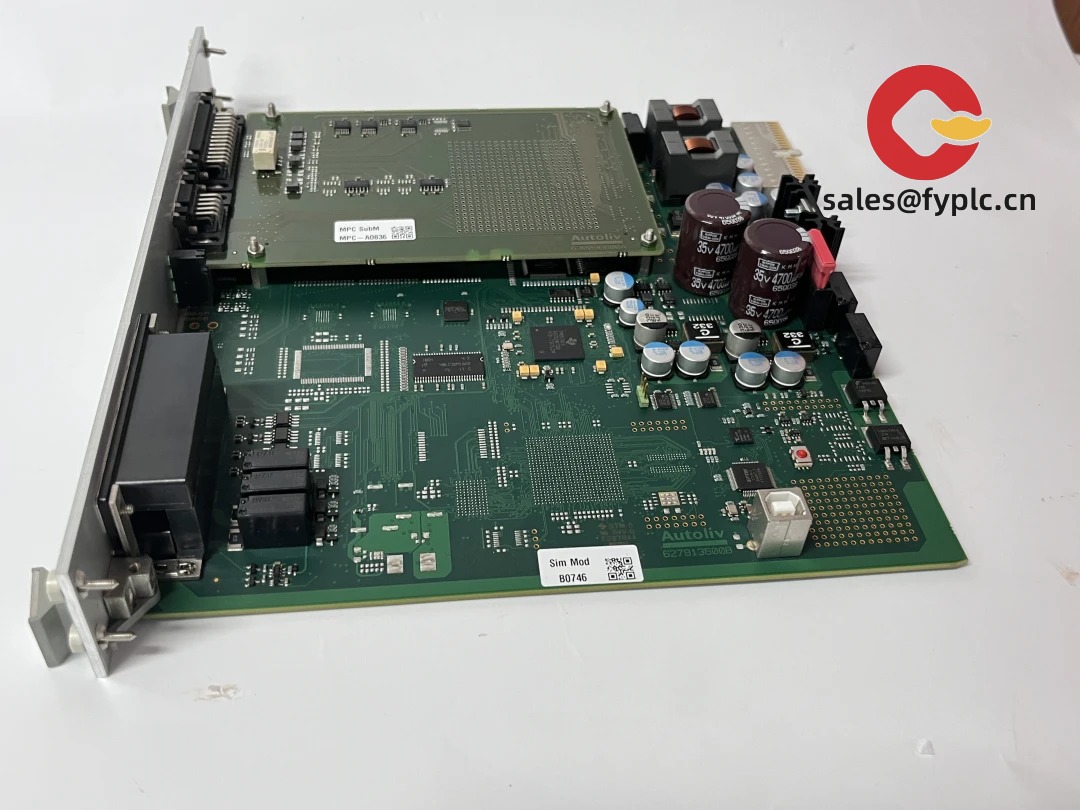

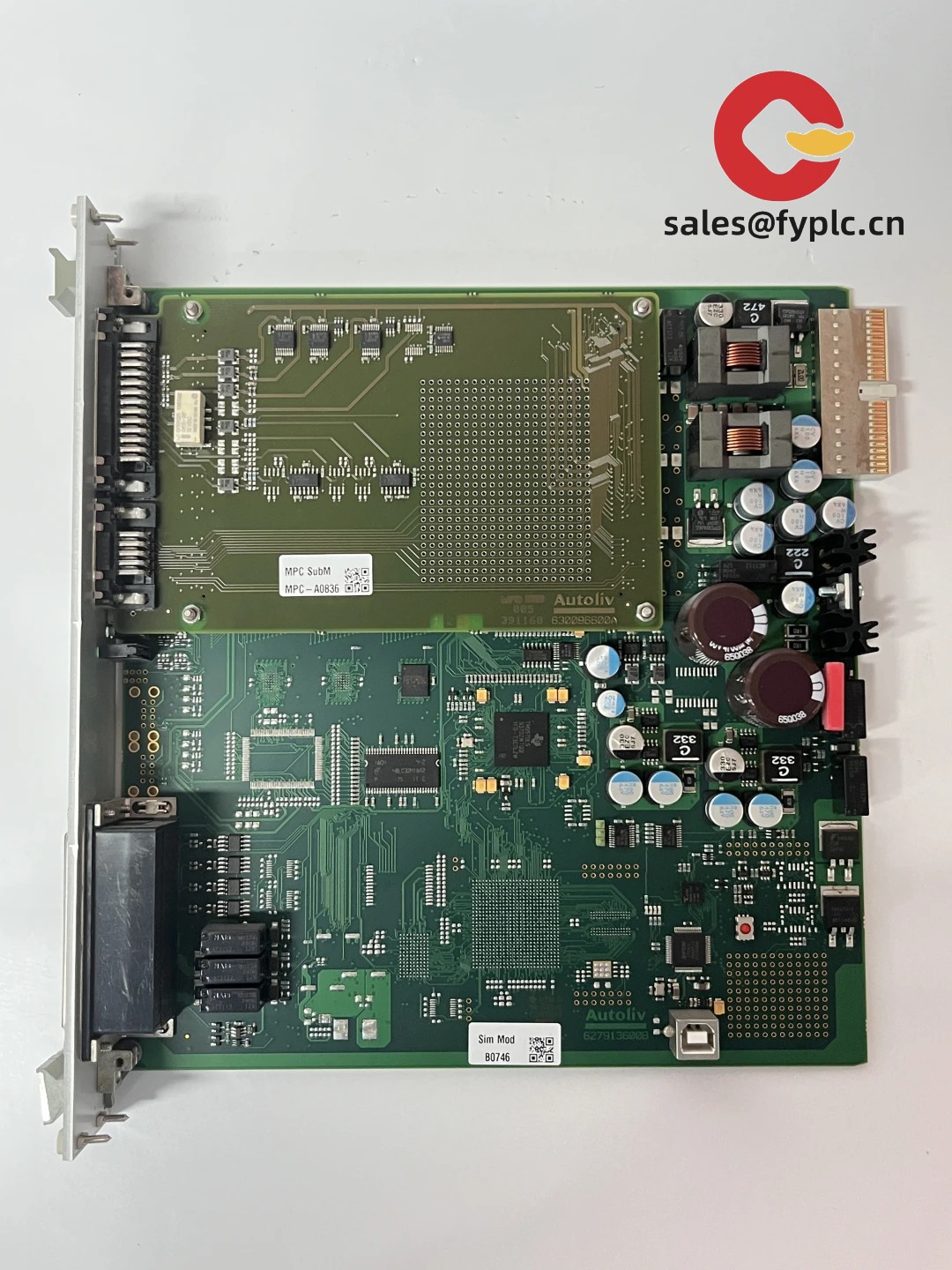

Autoliv Sim.Mod. B0760 (627913600B) – Simulation Module for Airbag/Restraint ECU Testing

The Autoliv Sim.Mod. B0760, part number 627913600B, is a simulation module used in restraint system testing—typically to emulate airbag squibs, seatbelt pretensioners, and related diagnostic lines during ECU validation or end-of-line checks. From my experience, teams value it for stable, repeatable loads and fault simulation without risking live pyrotechnic devices. You might notice that it integrates cleanly into existing test benches, which makes changeovers faster and cuts downtime during model switches.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

- Packaging: Anti-static and shock-protected, suitable for international transit

Key Features

- Restraint circuit emulation – Simulates airbag squib and pretensioner loads so you can test ECUs without pyrotechnic risks.

- Fault injection capability – Open/short conditions can be introduced to validate diagnostic behavior and DTC handling.

- Stable, repeatable loads – Precision components help keep test results consistent across stations and time.

- Harness-friendly integration – Typically plugs into existing Autoliv-style jigs or ATE racks to reduce rework.

- Safety-first design – Passive simulation approach and clear I/O segregation help prevent accidental deployment scenarios.

- Serviceable in the field – In many cases, contact wear parts can be cleaned or swapped to extend life between overhauls.

Technical Specifications

| Brand / Model | Autoliv Sim.Mod. B0760 (Part No. 627913600B) |

| HS Code | 903180 (Other measuring or checking instruments, appliances and machines) |

| Primary Function | Simulation module for airbag/pretensioner circuits and related diagnostic lines in ECU test benches |

| Power Requirements | Typically passive; where required, draws low-voltage power from the host test rack/backplane (no external PSU) |

| Operating Temperature | 0 to 40°C (lab/ATE environment) |

| Signal I/O Types | Resistive load emulation for squibs/pretensioners, analog sense lines, digital fault lines (open/short), CAN/LIN pass-through in many setups |

| Communication Interfaces | Via host fixture; supports ECU communication through CAN/LIN pass-through and discrete I/O as implemented by the test rack |

| Installation Method | Plug-in to test fixture/rack; secured with guide rails or captive screws (varies by ATE platform) |

| Dimensions & Weight | Compact module format suited for dense ATE or bench setups |

Application Fields

This module is typically used in:

- Airbag ECU end-of-line test stations (simulate firing loads and verify diagnostics)

- Engineering validation and DV/PV rigs for new restraint platforms

- Service and repair benches for automotive safety electronics

- Training or lab setups where live pyrotechnics are not permitted

A test engineer told us they swapped in the B0760 during a model year change and shaved about half a day off fixture rework because the harness mapping stayed consistent. That seems to be the common feedback—less fiddling, more testing.

Advantages & Value

- Safety and compliance – Removes live charge handling from routine tests, aligning with lab safety policies.

- Consistency across lines – Repeatable electrical characteristics help reduce false rejects and re-runs.

- Compatibility – Works smoothly with Autoliv-style harnessing and most mixed-vendor ATE racks.

- Lower operating cost – Extends fixture life and minimizes consumables compared with live-device testing.

- Responsive support – We assist with mapping to your pin-out and can pre-check against your test plan.

Installation & Maintenance

- Environment: Install in an ESD-safe cabinet with basic ventilation; avoid moisture and conductive dust.

- Wiring: Use shielded harnesses for diagnostics; label all connectors to match ECU pin-outs before power-up.

- Safety: Ensure no live pyrotechnic devices are connected while using simulation loads; lockout/tagout during re-cabling.

- Routine checks: Verify simulated load values at scheduled intervals; clean edge connectors with approved contact cleaner.

- Calibration: Where applicable, record load-tolerance measurements annually to maintain traceability.

- Firmware: If your rack uses a controller for fault scripting, keep the test script/firmware versions aligned with your MES.

Quality & Certifications

- Typically supplied in CE-compliant test environments; RoHS-compliant components are commonly used

- Manufacturing and supply chain commonly align with ISO 9001 practices

- Warranty: 365 days (repair/replace terms apply)

Reviews

There are no reviews yet.