Description

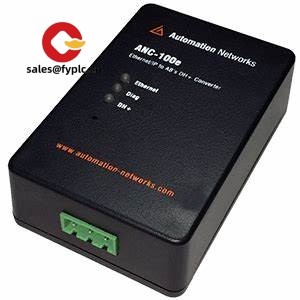

Automation Networks ANC-100e – Ethernet-to-DH+ bridge for Allen‑Bradley PLCs and HMIs

You might notice that “ANC-100e” isn’t an Allen‑Bradley catalog number. It’s a compact gateway from Automation Networks, widely used to connect Allen‑Bradley PLC‑5 and SLC 5/04 systems on DH+ (“blue hose”) to modern Ethernet networks. From my experience, it’s a practical way to get FactoryTalk, historians, or ControlLogix controllers talking to legacy DH+ nodes without touching the existing ladder logic. Typically, you mount it on a DIN rail, give it 24 VDC, set your DH+ baud rate and node, and you’re collecting data in minutes.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in‑stock items; no more than 1 month at the latest

- Payment: 50% advance; full payment before delivery

- Express delivery options: FedEx, UPS, DHL

Key Features

- Ethernet–DH+ Bridging – Links modern Ethernet clients and PACs to legacy DH+ devices (PLC‑5, SLC 5/04, PanelView on DH+).

- Multi‑rate DH+ – Supports common DH+ baud rates (typically 57.6 / 115.2 / 230.4 kbps) for mixed‑generation networks.

- 10/100 Ethernet – Standard RJ‑45 port for plant Ethernet; easy to drop into an existing controls VLAN.

- Explicit Messaging (CIP/PCCC) – Works with common Allen‑Bradley messaging and RSLinx/FactoryTalk clients in many cases, so you don’t rewrite PLC code.

- Web‑based Configuration – Browser access for setup, firmware updates, and basic diagnostics; quicker than serial-only tools.

- Industrial Build – DIN‑rail mounting, 24 VDC supply, DH+ port isolation for noisy panels.

- Diagnostics & LEDs – Status indicators and traffic counters help you verify comms and spot mis‑configurations fast.

- Firmware Upgradeable – Field‑updatable firmware to keep pace with site standards and security practices.

Technical Specifications

| Brand / Model | Automation Networks ANC-100e (Allen‑Bradley DH+ compatible) |

| HS Code | 8517.62 (Data transmission apparatus) |

| Power Requirements | 24 VDC nominal (typically 9–30 VDC), < 4 W |

| Operating Temperature | 0 to 60 °C (32 to 140 °F) typical panel environment |

| Signal Input/Output Types | 1 × DH+ channel (terminal connection), 1 × RJ‑45 Ethernet 10/100Base‑TX; status LEDs |

| Communication Interfaces | DH+ (57.6/115.2/230.4 kbps), TCP/IP, EtherNet/IP explicit messaging (PCCC bridging) |

| Installation Method | DIN‑rail mounting; panel enclosure (IP20) with proper ventilation |

| Dimensions & Weight | Compact DIN‑rail module; lightweight for crowded cabinets |

Application Fields

Plants that still rely on DH+ but need Ethernet access for SCADA, MES, or controller‑to‑controller messaging. It fits well in:

- Modernizing PLC‑5 and SLC 5/04 lines while adding historians or dashboards

- Bridging ControlLogix on EtherNet/IP to legacy DH+ devices for reads/writes

- Connecting PanelView terminals and legacy HMIs to plant Ethernet (for data collection or remote diagnostics)

- Industries such as food & beverage, automotive, metals, water/wastewater, and pulp & paper

Advantages & Value

- Non‑intrusive migration – In many cases, no PLC logic changes; preserves validated processes.

- Time savings – Web setup and clear LEDs shorten commissioning and troubleshooting.

- Compatibility – Plays nicely with common Rockwell tooling (RSLinx/FactoryTalk, MSG instructions) for DH+ access.

- Cost control – Avoids immediate rip‑and‑replace of DH+ infrastructure; phased upgrades become practical.

- Risk reduction – Electrical isolation and dedicated DH+ port help protect controllers on noisy networks.

- Supportability – Firmware upgrades and straightforward diagnostics make long‑term maintenance easier.

Installation & Maintenance

- Panel & power – Mount on DIN rail in a ventilated enclosure (IP20). Supply clean 24 VDC with proper grounding.

- DH+ wiring – Use shielded “blue hose” (e.g., Belden 9463 or equivalent). Set unique node addresses and the correct baud rate to match the segment. Keep stubs short and follow Rockwell DH+ cabling guidelines.

- Ethernet – Connect to a managed switch where possible; segregate with VLANs/QoS for control traffic.

- Safety – De‑energize circuits before wiring. Observe ESD precautions when touching terminals.

- Maintenance – Periodically back up config, review event logs, and update firmware during scheduled downtime. Inspect terminations and shielding annually; dust off the module during panel PMs.

Quality & Certifications

- Conformity: CE and RoHS (typical for this gateway class); FCC Class A emissions

- Manufacturing quality: Built for industrial control cabinets; designed for 24/7 operation

- Warranty: 12 months (365 days)

Supporting Components (recommended)

- 24 VDC DIN‑rail power supply sized for the gateway and panel margin

- DH+ “blue hose” cable (Belden 9463 or equivalent) and appropriate terminations/connectors

- Industrial RJ‑45 patch leads; managed switch with VLAN support for controls

- DIN‑rail and labeling kit for clean panel integration

Reviews

There are no reviews yet.