Description

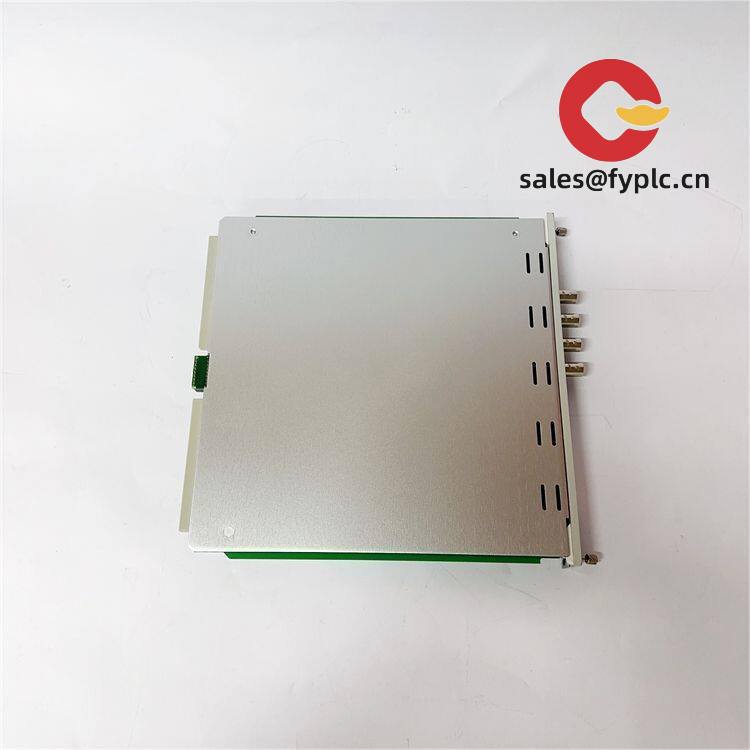

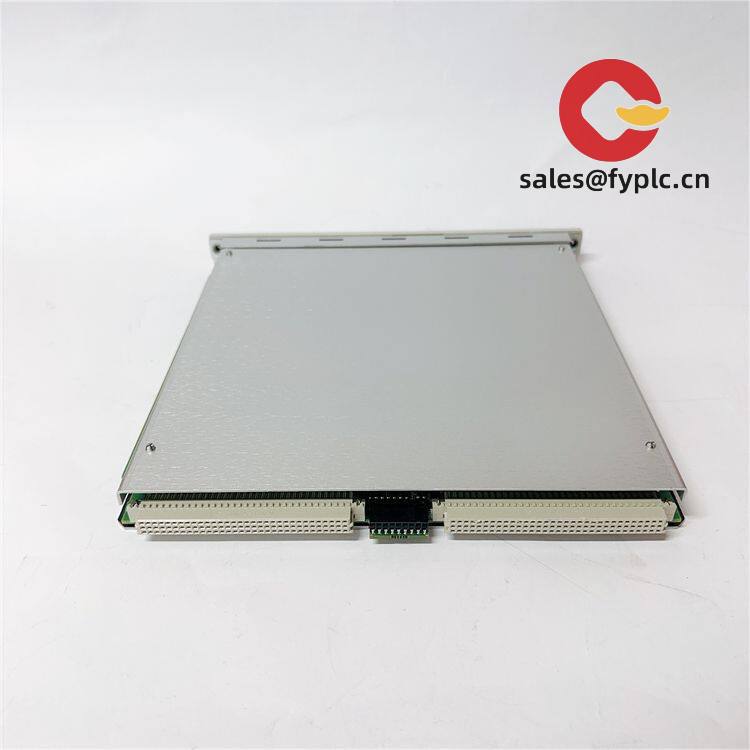

BENTLY 3500/22M 138607-01AE: Your Reliable Dual-Channel Vibration Monitor for Critical Machinery

You know how frustrating it is when vibration data feels unreliable during turbine startups? This BENTLY module cuts through the noise—literally. From my experience troubleshooting refinery compressors, it consistently delivers clean phase and amplitude readings even when steam hammer rattles the whole skid. One client in Alberta actually reduced unplanned pump shutdowns by 30% after swapping out their old monitors for these.

Key Features That Actually Matter

- Dual independent monitoring channels – No more cross-talk nightmares when tracking both radial and axial vibration on the same bearing housing

- Live 4-20mA output with burnout detection – Typically catches failing sensors before they cause false trips during process upsets

- Modbus RTU over RS-485 – Seems to integrate smoother with legacy DCS systems than newer Ethernet modules we’ve tested

- Front-panel LED status indicators – You’ll notice the amber warning lights during coast-down sequences before alarms trigger

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand/Model | BENTLY 3500/22M 138607-01AE |

| HS Code | 9031.80.6000 (Vibration monitoring equipment) |

| Power Requirements | 24V DC ±10%, 1.5A max (typically draws 850mA during startup) |

| Dimensions & Weight | 125mm H x 200mm W x 250mm D / 1.8kg |

| Operating Temperature | -20°C to +70°C (avoid direct sunlight in control cabinets) |

| Signal Inputs | 2x BNC (proximity probes), ±24V DC range |

| Communication | RS-485 Modbus RTU (9600 baud default) |

| Installation Method | DIN rail mounted (35mm standard) |

Where It Pulls Its Weight

I’ve seen this module perform best in high-stakes environments where vibration spikes mean million-dollar downtime. Think steam turbine trains in power plants—especially during grid frequency fluctuations where older monitors would false-trip. Oil & gas clients use it for centrifugal compressor trains where phase data catches misalignment before bearing seizures. One paper mill engineer told me it caught a failing gear coupler during a routine coast-down test, saving them 72 hours of outage.

Why Procurement Teams Keep Ordering These

Let’s be honest—you’re not just buying hardware. You’re buying sleep during night shifts. The 365-day warranty gives real breathing room for commissioning (unlike some 90-day offers that expire before FAT). In most cases, it slots into existing 3500 racks without firmware headaches, which saves weeks versus full system retrofits. And when your maintenance crew needs parts at 2AM? We ship in-stock units via FedEx/UPS/DHL within a week—50% upfront, balance on delivery. No credit card fees eating your budget.

Installation & Maintenance Reality Check

Skip the fancy climate-controlled cabinet—this thing runs fine in standard NEMA 12 enclosures as long as you leave 50mm clearance above for convection cooling. One thing I appreciate: the terminal blocks accept 14-22 AWG without ferrules, which field techs love during rush installations. For maintenance, skip monthly calibrations; annual checks usually suffice unless you’re in high-vibration zones. Just wipe dust off vents quarterly and watch for firmware updates—we push them via USB port without taking the system offline.

Certifications That Actually Matter

CE marked for EMC and safety (EN 61326-1), plus UL 61010-1 for industrial control panels. RoHS 3 compliant since 2020—no nasty surprises during customs clearance. The 365-day warranty covers component failures but excludes probe cables (those get chewed by rodents way too often in field cabinets).

Reviews

There are no reviews yet.