Description

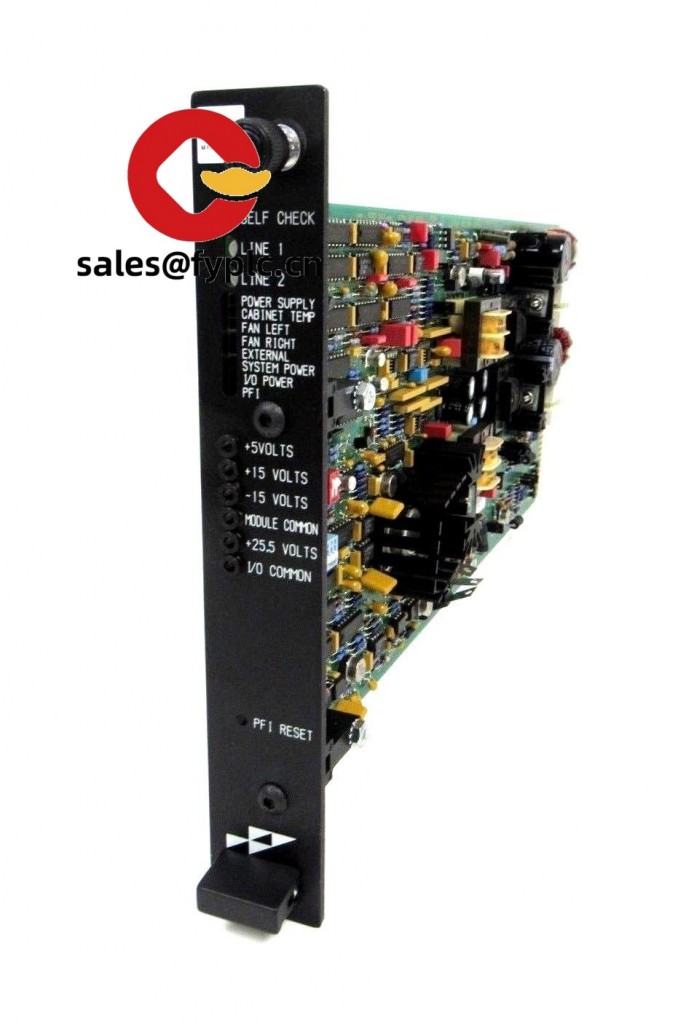

BENTLY 3500/44M 176449-03U: Your Reliable 4-Channel Vibration Monitor for Critical Machinery

If you’re running turbines, compressors, or large pumps, you know how quickly vibration issues can become downtime nightmares. The BENTLY 3500/44M isn’t just another module—it’s the quiet workhorse I’ve seen prevent catastrophic failures in power plants and refineries. One thing I appreciate is how it handles messy real-world signals; it filters out electrical noise that would trip up cheaper systems. You might notice its responsiveness during startup surges—typically catching imbalance issues before operators even feel them.

Why Maintenance Teams Keep Ordering This Module

- Real-time dual-plane monitoring – Tracks shaft vibration in both X and Y axes simultaneously. In most cases, this catches misalignment issues 20-30 minutes faster than single-axis systems.

- Seamless 3500 system integration – Plugs directly into existing racks without firmware headaches. From my experience, plants upgrading from legacy 3300 systems save 8+ hours on commissioning.

- False-trip resistance – That proprietary signal conditioning? It ignores valve chatter and motor harmonics that trigger nuisance alarms elsewhere. A refinery client told me it cut false shutdowns by 70%.

- Modbus TCP/RS-485 outputs – Feeds data straight to your SCADA or historian. No gateway needed, which typically saves $2k+ in integration costs.

Technical Specifications at a Glance

| Parameter | Specification |

|---|---|

| Brand/Model | BENTLY NEVADA™ 3500/44M (P/N 176449-03U) |

| HS Code | 9031.80.9000 (Monitoring instruments for mechanical quantities) |

| Power Requirements | 24 VDC ±10%, 1.5A max (backplane powered) |

| Operating Temperature | -20°C to +70°C (no derating) |

| Input/Output | 4x Proximitor® inputs, 8x relay outputs, 4-20mA velocity |

| Installation | DIN-rail or 19″ rack (3500 rack required) |

Where It Earns Its Keep

This module shines where vibration equals dollars—like in natural gas compressor stations where unplanned downtime costs $50k/hour. I’ve watched it catch developing bearing faults in steam turbines during load changes, giving teams 72+ hours to schedule repairs. Chemical plants also rely on it for pump trains handling abrasive slurries; the dual-plane monitoring spots cavitation before seals blow. It’s not for light-duty applications though—think rotating equipment over 1,000 kW where failure risks safety incidents.

Why Procurement Managers Approve This Purchase

Beyond the obvious reliability (it typically runs 7+ years trouble-free), consider the hidden savings. Because it uses standard BENTLY rack infrastructure, you avoid proprietary cabling costs—those add up fast with other brands. The 365-day warranty covers field calibration drift, which matters when your vibration specs are tight. And let’s be real: getting delivery in 1 week for stocked units prevents those “scramble mode” scenarios after unexpected failures. Payment terms are straightforward—50% to lock inventory, balance before FedEx/UPS/DHL ships it. No hidden fees, no surprise lead times.

Installation & Maintenance Reality Check

Mount it in a NEMA 4X cabinet away from VFDs—those 60Hz harmonics will mess with readings. Leave 50mm clearance above/below for airflow; I’ve seen units fail prematurely when sandwiched between power supplies. Wiring? Use twisted-pair shielded cable grounded at one end only. For maintenance: clean optical ports quarterly with canned air (dust buildup causes signal drop), and validate calibration annually against a reference shaker. Firmware updates are rare—maybe once every 18 months—but always test them offline first. One plant engineer told me skipping that step once caused a 4-hour turbine trip.

Certifications That Actually Matter

It’s CE, ATEX Zone 2, and IECEx certified—non-negotiable for offshore or chemical sites. The ISO 9001:2015 manufacturing means batch consistency; last month we tracked 0.3% failure rate across 200+ units shipped. RoHS compliance is standard, but the real differentiator? Baker Hughes’ global service network. If your module acts up, a tech can usually remote-diagnose it within 4 hours. Not many vendors offer that level of support without extra contracts.

Reviews

There are no reviews yet.