Description

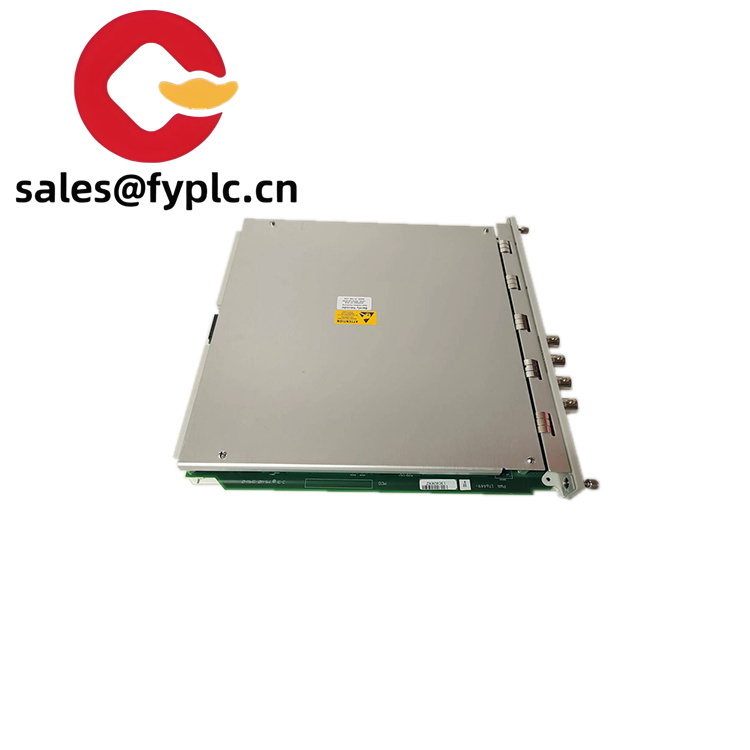

Bently 350042M-176449-02 Redundant Transmission Module Controller

The Bently 350042M – 176449 – 02 is a key part of the 3500 monitoring system, specifically functioning as a [describe the product type, e.g., four – channel machinery protection module]. Its core purpose is to [describe the main function, e.g., continuously monitor and protect industrial machinery by precisely measuring multiple critical parameters such as vibration, displacement, and speed]. In industrial setups, it acts as a vigilant guardian, constantly collecting data from sensors and analyzing it to detect any deviations from normal operating conditions. Whether installed in a large – scale power generation plant, a petrochemical refinery, or a high – volume manufacturing facility, the 350042M – 176449 – 02 integrates seamlessly into the existing industrial monitoring infrastructure.

Technical Highlights Table:

|

Label

|

Specification

|

|

Model Number

|

350042M – 176449 – 02

|

|

Brand

|

Bently

|

|

Type

|

[Product type, e.g., Four – Channel Machinery Protection Module]

|

|

Input Voltage

|

[Specify the accurate input voltage range, e.g., 18 – 32 V DC]

|

|

Operating Temp

|

-40°C to 85°C (Operating)

|

|

Communication Method

|

Ethernet, Profibus, Modbus TCP

|

|

Mounting

|

Designed for installation in a 3500 rack

|

|

Weight

|

Approximately [X] kg

|

|

Certifications

|

CE, UL, ISO 9001

|

|

Dimensions

|

[Length] x [Width] x [Height] mm

|

|

Measurement Channels

|

4 channels

|

|

Measurement Parameters

|

Vibration, Displacement, Speed, and more

|

|

Measurement Accuracy

|

[Specify accuracy level, e.g., ±0.5% of full scale]

|

|

Signal Outputs

|

Analog (4 – 20 mA), Digital (Ethernet – based data packets)

|

For more information, please click on the following link:

AB 2711 series 2711-K6C15 touch screen accessories

Rockwell 1762-OW16 Safety Output Module Relay

Triconex 3009 Enhanced Main Processor (UMP) Module

Triconex 3101/Triconex3201 Triple Modular Redundant Main Processor

AB 2711-K6C5 touch screen human-machine interface function module

Allen Bradley 1769-L32C | Processor Analog Input/Output Module

ABB UFC718AE01-HIEE300936R0001 Power Control Equipment Module

Reviews

There are no reviews yet.