Description

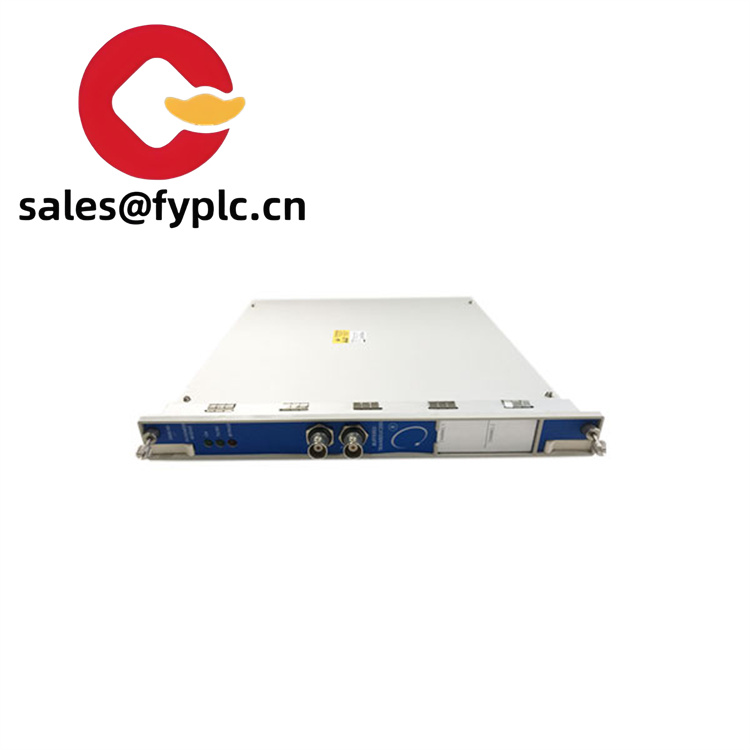

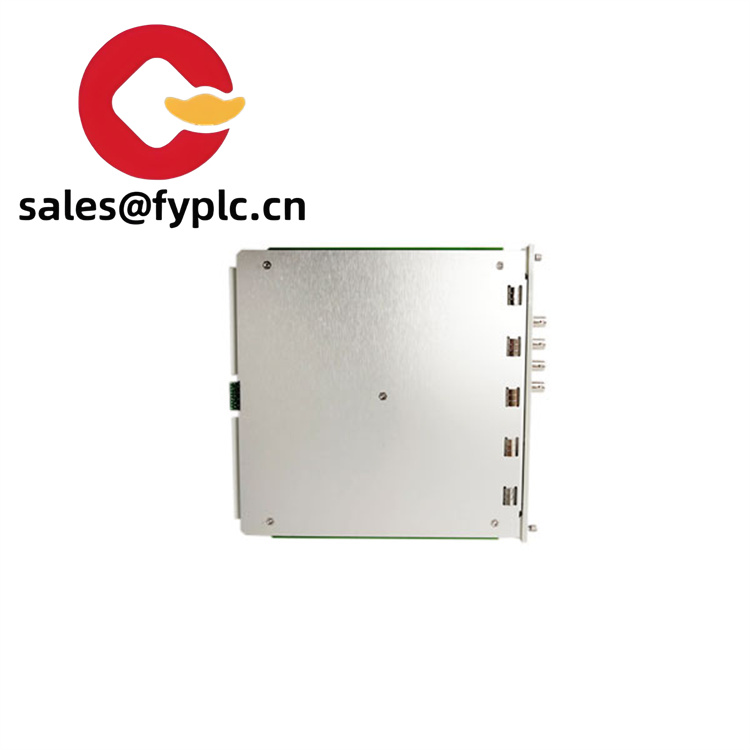

Bently 350045 Channel Position Monitoring Module

In the realm of industrial automation, maintaining the structural integrity of rotating equipment is paramount to prevent catastrophic failures and ensure operational continuity. The BENTLY 350045 Position Monitor Module stands as a cornerstone solution, engineered to deliver real-time insights into machinery health through advanced axial position, differential expansion, and valve position monitoring. As part of Bently Nevada’s renowned 3500 Series, this 4-channel module integrates seamlessly into predictive maintenance frameworks, supporting applications in power generation, oil refining, and chemical processing. Its robust design and configurable alarm logic make it indispensable for safeguarding turbines, compressors, and other high-value assets against misalignment, thermal stress, and mechanical wear.

| Label | Specification |

|---|---|

| Model Number | 350045 |

| Brand | Bently Nevada |

| Type | 4-Channel Axial Position & Differential Expansion Monitor |

| Input Voltage | 24V DC |

| Operating Temp | -40°C to +70°C |

| Communication Method | RS-485 (Modbus RTU), Analog (4–20 mA) |

| Mounting | DIN rail |

| Weight | 0.9 kg |

| Certifications | CE, ISO 9001 |

| Dimensions | 2.6 cm x 25.8 cm x 24 cm |

| IP Rating | IP65 |

| Protocols Supported | Modbus RTU, Bently Nevada Proprietary Protocol |

The BENTLY 350045 excels in precision and adaptability, making it ideal for mission-critical applications. Its advanced signal conditioning delivers ±0.2% measurement accuracy, ensuring reliable detection of even subtle deviations from baseline conditions . The module’s wide operating temperature range (-40°C to +70°C) and IP65 rating safeguard against dust, moisture, and extreme environments, while electromagnetic compatibility (EMC) minimizes interference in high-noise settings like steel mills or petrochemical plants .

The BENTLY 350045 plays a pivotal role in industries where thermal expansion and axial movement pose significant risks. In oil refining, it monitors compressor casing expansion to prevent seal failure during start-up/shutdown cycles, ensuring compliance with API 617 standards. Similarly, in power generation, the module tracks turbine rotor axial position to avoid blade-to-stator contact, protecting multimillion-dollar assets from catastrophic damage .

Compatible and Related Models

For more information, please click on the following link:

ABB PCD232A Exciter Control Module Unit

Motorola MVME2400 Sandwich Board PCI Processor

NI PCI-5421 Signal Acquisition Card Signal Generator

PROSOFT MVI56E-MNETC Communication Multi Series Module

GE PCH1026 Vibration Sensor Digital Structural Vibration Monitor

Reviews

There are no reviews yet.