Description

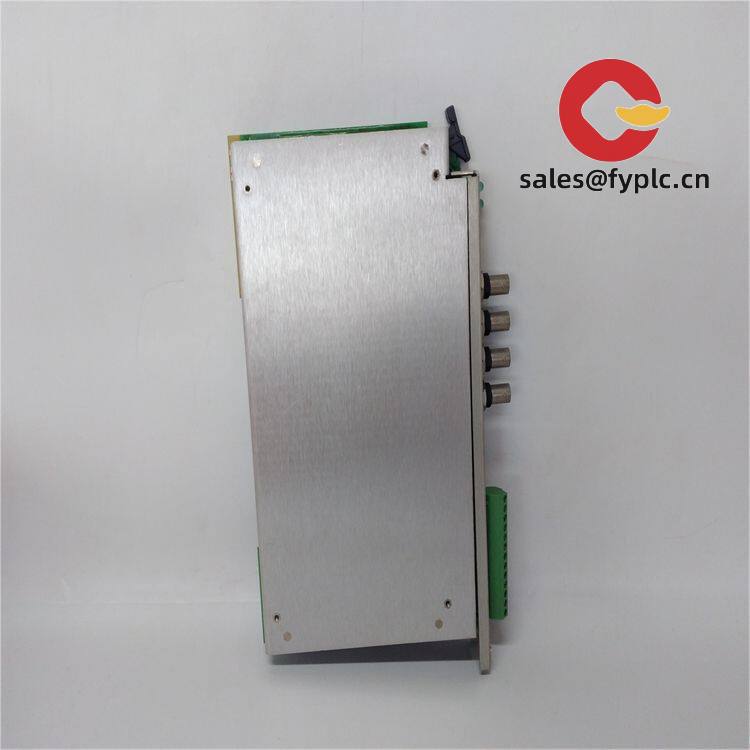

Bently Nevada 125388-01 Half-Height Module – Compact I/O interface for machinery condition monitoring racks

The Bently Nevada 125388-01 is a half-height plug-in module designed for Bently Nevada rack-based monitoring systems. From my experience, this module is typically used where a compact footprint and straightforward rack integration are important—think turbine trains, compressors, or large pumps where you want dependable connectivity without consuming a full-height slot. You might notice that many teams use it as a service-friendly I/O or interface position within their condition monitoring rack to keep channel density high and changeout times low.

Our Order Process & Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment, full payment before delivery

- Shipping: FedEx, UPS, DHL

Key Features

- Half-height form factor: Conserves rack space while maintaining standard Bently Nevada handling and installation practices.

- Backplane-powered: No external power feed; draws power via the system backplane for clean wiring and easier commissioning.

- Service-friendly design: Front-insert, secure with retaining hardware; typically a quick swap during planned outages.

- Rack integration: Works within Bently Nevada rack-based monitoring architectures; communication handled via the internal backplane.

- Status indication: Front indicators (where applicable) provide quick visual checks to reduce troubleshooting time.

- Industrial build quality: Built for continuous operation in plant environments; conformal-coat variants may exist depending on build code (–01).

Technical Specifications

| Brand / Model | Bently Nevada 125388-01 (Half-height module) |

| HS Code | 9031.80 (Measuring or checking instruments – other) |

| Power Requirements | Supplied via system backplane; no external power connection |

| Operating Temperature | Typically 0 to +65°C, non-condensing environment recommended |

| Signal I/O | Rear rack I/O connection; signal types depend on system configuration |

| Communication Interface | Internal backplane interface within Bently Nevada rack |

| Form Factor | Half-height, plug-in front module with retaining hardware |

| Installation Method | Front insertion into Bently Nevada monitoring rack; secure and connect via backplane |

| Certifications (typical) | CE, RoHS; UL/CSA recognition in many cases |

Application Fields

Built for continuous-duty monitoring systems, the 125388-01 fits plants where reliability matters more than frills. Typical sites include oil & gas compressor stations, steam or gas turbine halls, petrochemical pumps and blowers, as well as paper mills and mining drives. One maintenance lead told us they swapped a 125388-01 during a planned outage and brought the train back online in minutes—the half-height footprint made the spare strategy simpler.

Advantages & Value

- Reliability: Designed for continuous operation in harsh industrial environments.

- Compatibility: Integrates with Bently Nevada rack architectures via backplane—no special wiring tricks in most cases.

- Cost control: Half-height format helps increase channel density and reduce cabinet space costs.

- Serviceability: Fast replacement and straightforward checks reduce downtime during outages.

- Support: We assist with part verification (build code, revision) before shipment to avoid misfits.

Installation & Maintenance

- Cabinet standards: Install the rack in a 19-inch cabinet with proper earthing; keep at least 25 mm clearance for airflow.

- Environment: Clean, dry, and within the stated temperature range; avoid corrosive gas exposure.

- Power and wiring: Use the approved Bently Nevada rack power supply; route signal wiring separately from power to minimize noise.

- Safety: De-energize the rack or place the system in a permissive state before module changeout to prevent trips.

- Routine checks: Inspect terminal tightness and connectors quarterly; clean dust with dry air; verify firmware and configuration at the system level if applicable.

- Spare strategy: Keep at least one half-height spare on site for critical trains to shorten MTTR.

Quality & Certifications

The 125388-01 is supplied new or professionally inspected (depending on sourcing) and is typically compliant with CE and RoHS requirements; UL/CSA recognition is common across this family. Manufacturer policies usually provide a standard warranty; we cover the unit with a 365-day guarantee and functional testing before dispatch.

Tip: Part numbers with suffixes (like “-01”) can indicate specific build options. If you share your existing rack’s module map or build code, we’ll double-check compatibility before shipment.

Reviews

There are no reviews yet.