Description

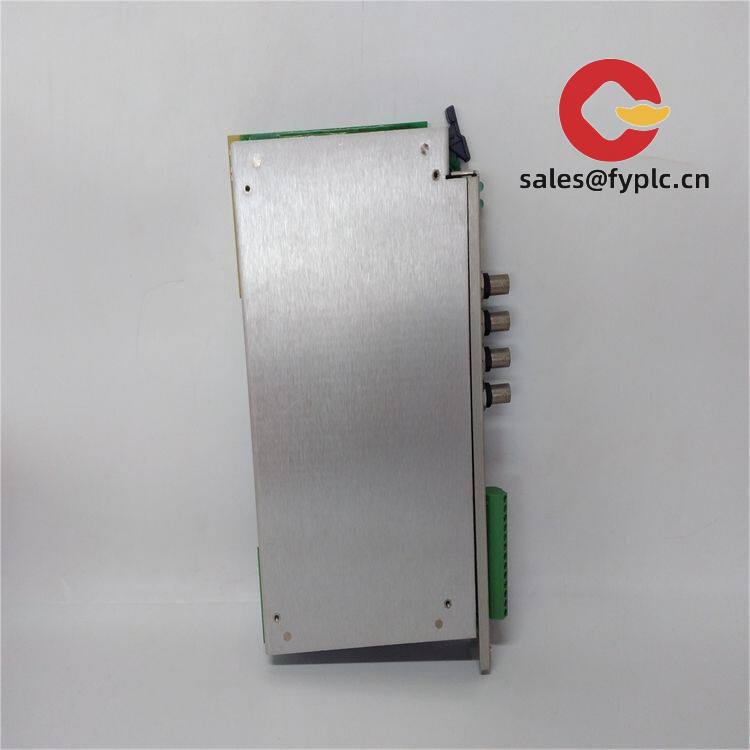

Bently Nevada 125696-01 4-Channel Relay Module – Trusted alarm and trip outputs for 3500 machinery protection racks

The Bently Nevada 125696-01 is a 4-channel relay module designed for the 3500 series rack, providing clean, configurable dry-contact outputs for alarms, shutdowns, and interlocks. From my experience, it’s the go-to choice when you need reliable relay signaling from vibration and condition monitoring measurements to your DCS/ESD or annunciator panels. You might notice that the configuration flexibility (latching, voting, and contact state) typically reduces nuisance trips and makes compliance testing a lot easier.

Company’s Order Placement Process and Guarantees

-

- – Warranty: 365 days

-

- – Delivery: 1 week if in stock; no more than one month at the latest

-

- – Payment: 50% advance payment; full payment before delivery

- – Express options: FedEx, UPS, DHL

Key Features

- Four independent relay outputs – Each channel provides a dry-contact output for alarm, trip, or interlock signaling.

- Configurable contact behavior – SPDT (Form C) contacts; typically configurable as normally energized/de-energized and NO/NC to fit site standards.

- Alarm logic and voting – Supports common logic (e.g., OR/AND groupings) so you can implement simple voting schemes without extra hardware.

- Latching or non-latching – Set per application; many plants prefer latching trips with manual reset for audits and safety workflows.

- Rack-powered – No external power supply; the module draws from the 3500 backplane for tidy cabinet layouts.

- Status indication – Clear front-module status makes commissioning faster and troubleshooting more straightforward.

- Single-slot footprint – Saves space and simplifies I/O assignment in dense racks.

- Designed for industrial environments – Works reliably in control room conditions with stable performance over time.

Technical Specifications

| Brand / Model | Bently Nevada 125696-01 (4-Channel Relay Module for 3500) |

| HS Code | 8537.10 – Boards/panels for electric control (≤1000 V) |

| System Compatibility | Bently Nevada 3500 rack system |

| Power Requirements | Powered via 3500 backplane; no external supply required |

| Channels | 4 relay outputs, SPDT (Form C), dry contacts |

| Signal I/O Types | Dry-contact relay outputs for alarms/trips; field wiring via rear I/O terminals |

| Communication Interfaces | Configuration through the rack; no dedicated fieldbus on the module |

| Operating Temperature | Typically 0 to +65°C (control room environment) |

| Installation Method | Single-slot plug-in module; rear I/O with screw terminals on the rack’s I/O module |

| Dimensions & Weight | Standard 3500 single-slot form factor; typical weight under 1 kg |

Recommended Supporting Components

- Bently Nevada 3500/05 System Rack – The chassis for housing monitor and relay modules; choose slot count according to channel density.

- Bently Nevada 3500/15 Power Supply – Reliable rack power; many sites keep a spare for uptime assurance.

- Bently Nevada 3500/22M TDI – Typically used for rack configuration and data interface to software; streamlines setup and diagnostics.

- Bently Nevada 3500/92 Communications Gateway – Modbus communications to DCS/PLC for system-level integration when needed.

One thing I appreciate is how cleanly the 4-channel relay module ties into these standard rack elements—wiring stays organized and future expansions remain straightforward.

Application Fields

Common in machinery protection and plant safety where deterministic alarm outputs are required:

- Steam and gas turbines – trip relays linked to vibration/overspeed alarms.

- Compressors, pumps, and fans – start-permissive and shutdown logic to prevent damage.

- Refining and petrochemical units – interlocks to ESD/SIS for equipment protection.

- Power generation and paper mills – annunciation to DCS/PLC for operator awareness.

In many cases, plants map two channels to alarms and two to trips, with simple voting to reduce spurious trips during transient conditions.

Advantages & Value

- Reliability – Proven module architecture designed for continuous operation in critical control environments.

- Compatibility – Seamless with the 3500 ecosystem; no surprises on wiring or configuration.

- Cost Efficiency – Consolidates multiple alarm functions into one single-slot module; helps standardize spares.

- Configuration Flexibility – Voting, latching, and contact-state options let you match site standards without extra hardware.

- Support – Easier commissioning and maintenance with standard rack tools and clear status indications.

Installation & Maintenance

- Panel/Cabinet – Install in a clean, ventilated control cabinet; follow standard 3500 rack mounting and grounding practices.

- Wiring – Use the rear I/O terminals; maintain separation from high-voltage conductors and label alarm/trip circuits clearly.

- Contact Ratings – Use as dry-contact signal interfaces into DCS/ESD input cards; drive higher loads via interposing relays if required.

- Configuration – Set channel assignment, latching, and voting using the standard 3500 rack configuration tool; document setpoints and logic.

- Safety – De-energize circuits when landing wires; verify function with loop checks. You might notice that a proof-test schedule reduces surprises later.

- Routine Maintenance – Periodic functional tests of each relay output, inspection of terminal tightness, and cleaning of the front panel and ventilation paths.

Quality & Certifications

- CE and UL/cUL compliance (industrial control equipment)

- RoHS compliant in most configurations

- Manufacturer warranty policies apply; sales warranty from us: 365 days

If you’re standardizing a 3500 rack or replacing legacy relay cards, this module seems to be the safest drop-in path—minimal rework, predictable behavior, and clean integration to your control system.

Reviews

There are no reviews yet.