Description

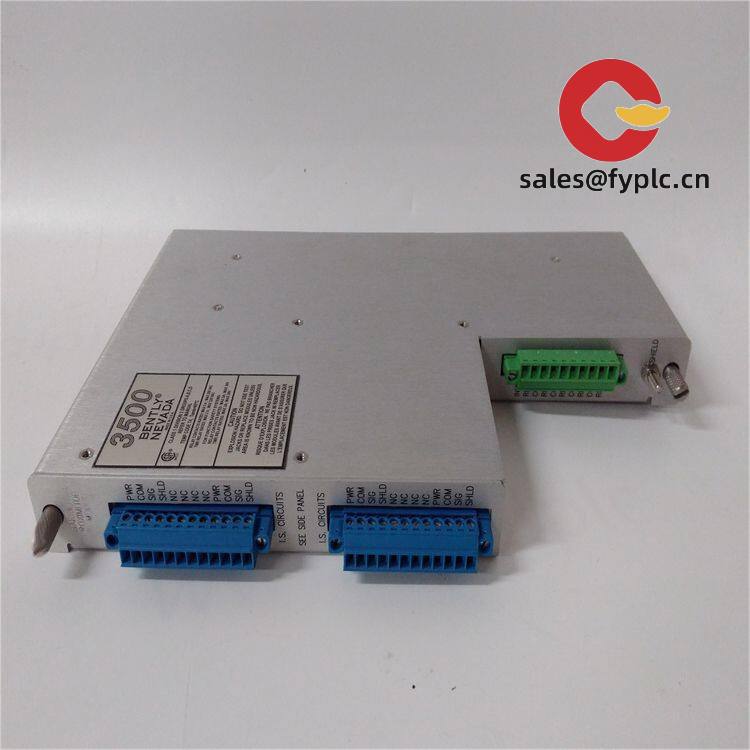

Bently Nevada 132417-01 Vibration Monitoring Module – Machine Protection and Condition Monitoring for Critical Rotating Assets

The Bently Nevada 132417-01 is a dedicated vibration monitoring module designed for continuous protection and trending of rotating machinery. From my experience, it’s typically deployed in Bently Nevada 3500 series racks to watch over bearings, shafts, and casing vibration in real time, feeding both trip logic and plant-wide condition monitoring. You might notice that it balances two priorities quite well: fast, reliable machine protection and clean data for predictive maintenance systems.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Continuous vibration monitoring – Designed for round-the-clock protection of turbines, compressors, pumps, and fans where shutdown risk must be minimized.

- Multi-sensor compatibility – Works with proximity probes and seismic/accelerometer inputs (depending on I/O option), making it easy to standardize across mixed fleets.

- Dual-level alarms – Alert and Danger setpoints per channel are typically available for precise trip logic and operator awareness.

- Buffered outputs – Buffered dynamic signal available on the I/O module for portable analyzers and diagnostics without disturbing the process.

- System integration – Communicates through the rack to the 3500/22M comms interface for Ethernet connectivity to DCS, PLC, or condition monitoring software.

- Proven reliability – Industrial-grade design with long service life; seems to be a common choice in API 670-style machine protection architectures.

Technical Specifications

| Brand / Model | Bently Nevada 132417-01 |

| Product Type | Vibration Monitoring Module (for Bently Nevada machine protection racks) |

| HS Code | 903180 (Measuring/monitoring instruments) |

| Power Requirements | Supplied via the Bently Nevada rack backplane (no external power to the front module) |

| Signal I/O Types | Dynamic vibration inputs from proximity probes or accelerometers (per I/O option); buffered output available on the I/O module; OK/Alarm/status via rack |

| Communication Interfaces | Via the system communications module (e.g., 3500/22M) for Ethernet/Modbus TCP and condition monitoring software connectivity |

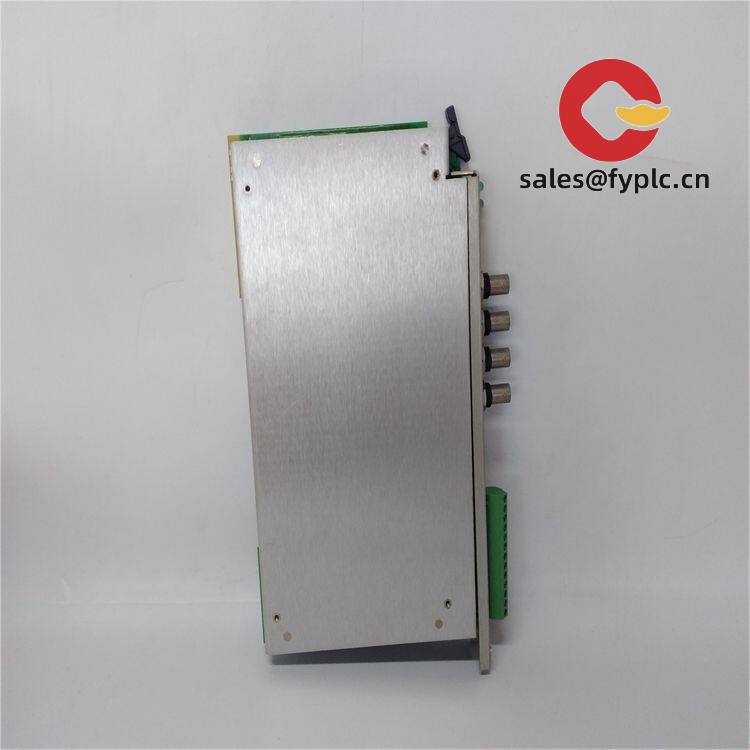

| Installation Method | Front monitor card + matching rear I/O module; installs in standard Bently Nevada 19-inch rack slot with screw/plug terminals on the I/O |

| Operating Temperature | Typically 0 to +65 °C for rack-mounted modules (refer to the specific datasheet for exact limits) |

| Dimensions & Weight | Standard Bently Nevada rack-slot module (front card + rear I/O); same form factor as other 3500 monitors |

Application Fields

This module fits best where continuous vibration protection and trending is non-negotiable:

- Oil & gas: gas compressors, turbine trains, pipeline pump stations

- Power generation: steam/gas turbines, generator bearings, ID/FD fans

- Chemicals & refining: critical pumps, agitators, and expanders

- Pulp & paper, mining & metals: large motors, blowers, and mill drives

- Water & wastewater: high-duty pumping assets in unattended stations

A maintenance lead at a combined-cycle plant told us: “We standardized on this monitor across two units. The buffered output makes field analysis straightforward, and our trip logic has been rock solid.”

Advantages & Value

- Compatibility – Works within the Bently Nevada protection architecture, simplifying spares and training.

- Reliability – Industrial design with proven uptime in harsh environments, which in many cases reduces nuisance trips.

- Lifecycle savings – Standardized modules mean faster replacement and less engineering effort during turnarounds.

- Data clarity – Clean vibration signals and buffered outputs support better diagnostics and earlier fault detection.

- Integration flexibility – Communicates through the rack to DCS/PLC/SCADA and condition monitoring platforms without awkward gateways.

Installation & Maintenance

- Panel/Rack – Install in a Bently Nevada rack mounted in a clean, dry cabinet; allow ventilation and avoid high EMI sources.

- I/O Pairing – Ensure the correct rear I/O module for your sensor type (proximity or accelerometer) and wiring style.

- Wiring – Use shielded, twisted pairs for sensor leads; ground shields at one end; maintain tight routing away from power cables.

- Configuration – Set Alert/Danger setpoints, filtering, and logic per machine standards; verify OK/status before startup.

- Routine care – Periodically check terminal torque, clean dust from the rack, verify sensor bias/OK, and back up configuration files.

- Firmware – When applicable, keep system firmware aligned across rack modules; update during scheduled outages.

- Safety – De-energize the rack slot before changing I/O wiring; follow site LOTO and ESD handling practices.

Quality & Certifications

- Manufacturer quality system: ISO 9001

- Typical compliance: CE marking; UL/cUL for industrial control equipment

- RoHS: commonly compliant for monitoring electronics (check the exact build revision)

- Manufacturer warranty: typically 1 year (may vary by region and contract)

One thing I appreciate is how easily this module drops into existing Bently Nevada racks without rethinking the full protection strategy. If your scope includes proximity probes (shaft vibration/position) or accelerometers (casing vibration), this model streamlines both protection and diagnostics with minimal wiring changes.

Reviews

There are no reviews yet.