Description

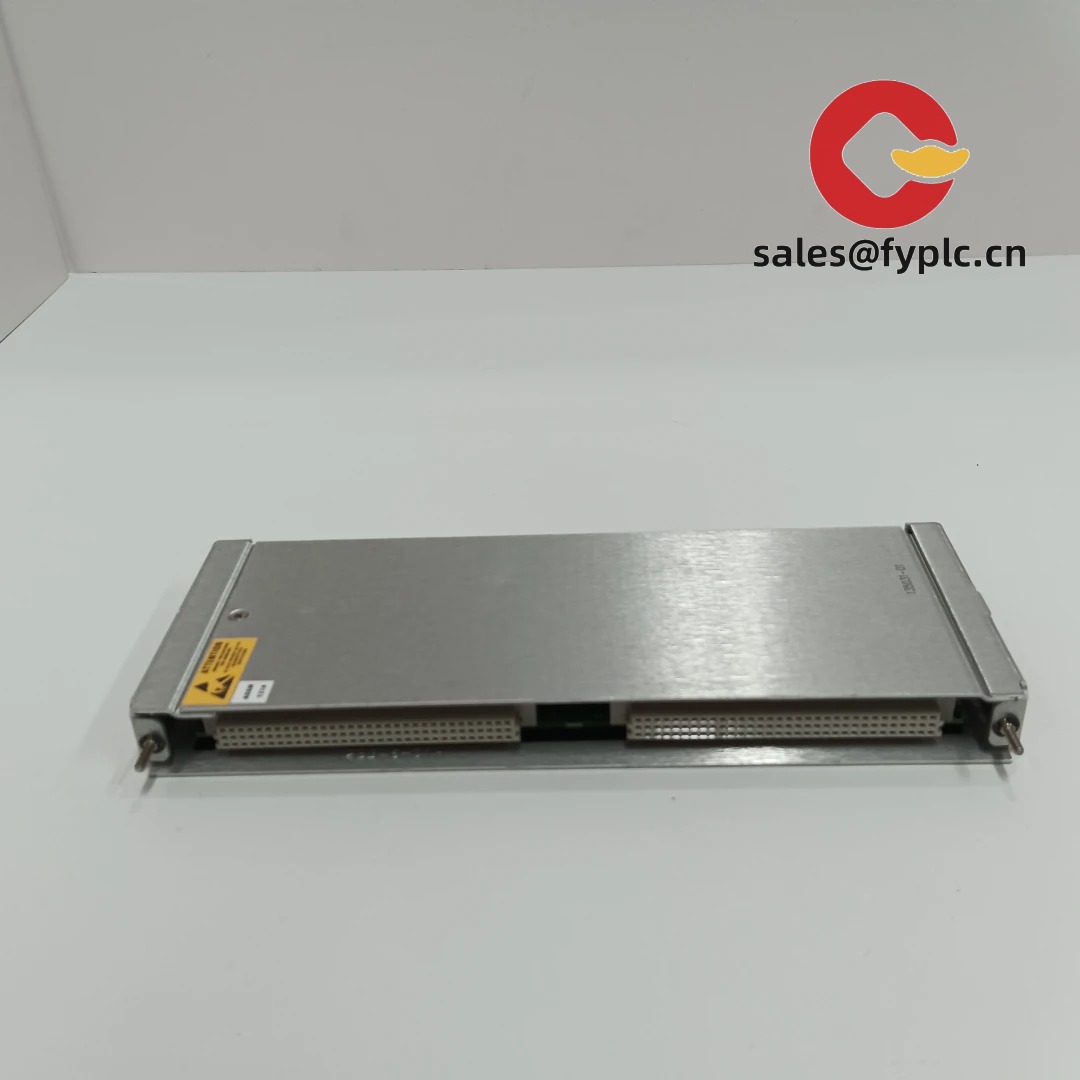

Bently Nevada 135031-01 Rack Interface I/O Module – Reliable rack communications for 3500 Series protection systems

The Bently Nevada 135031-01 is the Rack Interface I/O Module typically paired with the 3500/22M TDI to provide stable rack-wide communications, status signaling, and external contacts for plant systems. From my experience, this part is chosen as a like-for-like replacement during planned turnarounds, or as a strategic spare to keep a 3500 rack online with minimal downtime.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Purpose-built for 3500 racks: Works with 3500/22M TDI to handle rack communications and status signaling in most installations.

- Stable Ethernet/serial connectivity: Typically provides 10/100Base‑T Ethernet and a service serial port to interface with System 1 software or plant DCS gateways.

- Rack health and control contacts: Commonly includes terminals used for Rack OK status, Remote Reset, and similar dry-contact functions (varies by configuration).

- Plug-and-play serviceability: Rear I/O form factor slides into the rack backplane, keeping wiring tidy and change-outs quick.

- Industrial temperature range: Designed for control cabinets in harsh areas; suitable for continuous operation in many cases.

- Backwards-compatible design: Fits standard 3500 Series architecture without special adapters.

- Low maintenance: No periodic calibration; basic visual checks and connector tightening usually suffice.

Technical Specifications

| Brand / Model | Bently Nevada 135031-01 (Rack Interface I/O Module for 3500 Series) |

| HS Code | 9032.89 (Automatic regulating or controlling instruments; final HS code may vary by region) |

| Power Requirements | Powered via 3500 rack backplane; no external power supply required |

| Operating Temperature | Typically -30°C to +65°C (aligned with 3500 Series environmental ratings) |

| Signal I/O Types | Dry-contact terminals for rack status/control (e.g., Rack OK, Remote Reset; configuration dependent) |

| Communication Interfaces | Ethernet 10/100Base‑T (RJ-45) and a service serial port (RS‑232) in most cases |

| Installation Method | Rear-mounted I/O card; mates to 3500 rack backplane and the 3500/22M TDI |

| Dimensions & Weight | Standard 3500 I/O module footprint; occupies one rear I/O position |

Application Fields

You’ll typically find the 135031-01 in critical machinery protection setups where continuous data and rack status are essential:

- Oil & Gas: compressors, pumps, and turbo machinery in upstream and downstream facilities

- Power Generation: steam and gas turbines, balance-of-plant rotating assets

- Chemical & Petrochemical: process pumps, fans, and blowers with DCS integration

- Pulp & Paper / Mining: high-duty rotating equipment where uptime is paramount

“Swapping in the 135031-01 cut our rack comms troubleshooting from hours to minutes. It was a straight fit behind the TDI.” — Maintenance Supervisor, gas-fired power plant

Advantages & Value

- Reliability under load: Stable rack communications reduce nuisance trips and data loss during transient events.

- Compatibility assurance: Designed for the 3500 architecture; no surprises with wiring or connectors.

- Cost-effective maintenance: Replace the I/O module instead of disturbing the entire rack—less risk and less downtime.

- Lifecycle support: Easier to keep critical spares; simplifies shutdown planning and recovery.

- Integration-ready: Interfaces cleanly to plant networks and historians through the TDI.

Installation & Maintenance

- Mounting: Rear of 3500 rack; ensure the 3500/22M TDI is properly seated before securing the I/O module.

- Cabinet & ventilation: Install in a clean, dry control cabinet with adequate airflow; avoid heat sources and condensation.

- Wiring: Use shielded twisted pairs for control contacts where applicable; maintain proper grounding and segregation from power cables.

- Network: For Ethernet, use industrial-rated CAT5e or higher; keep cable runs within recommended lengths; verify link speed/duplex on the switch.

- Safety: De-energize the rack before removal/installation; observe ESD precautions; confirm terminal labeling prior to reapplying power.

- Routine checks: Quarterly visual inspection of terminals and shields; clean dust with dry air; verify Rack OK contact operation during scheduled tests.

- Firmware alignment: Keep TDI firmware and configuration backups current; in many cases, this prevents mismatch alarms after maintenance.

Quality & Certifications

- CE marked; UL/cUL recognition typically applicable to the 3500 Series assemblies

- RoHS compliance in most markets

- Manufacturing quality aligned with ISO-based processes

- 365-day warranty and functional testing prior to shipment

Commonly Paired Components

- Bently Nevada 3500/22M TDI (Transducer Interface) – primary rack communications module

- Bently Nevada 3500/25 Keyphasor Module – phase reference for speed/phase measurements

- Bently Nevada 3500/40M, 3500/42M series – dynamic measurement modules

- Bently Nevada 3500 Power Supply Modules – AC or DC options for the rack

If you’re replacing a failed I/O or building a spare kit, the 135031-01 seems to be the practical choice—straightforward install, predictable results, and no surprises with 3500 rack wiring.

Reviews

There are no reviews yet.