Description

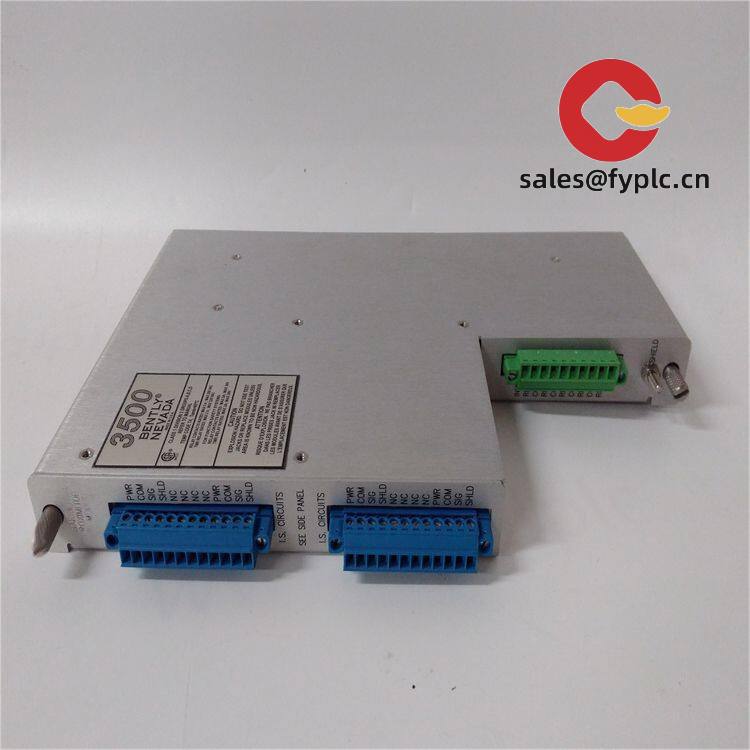

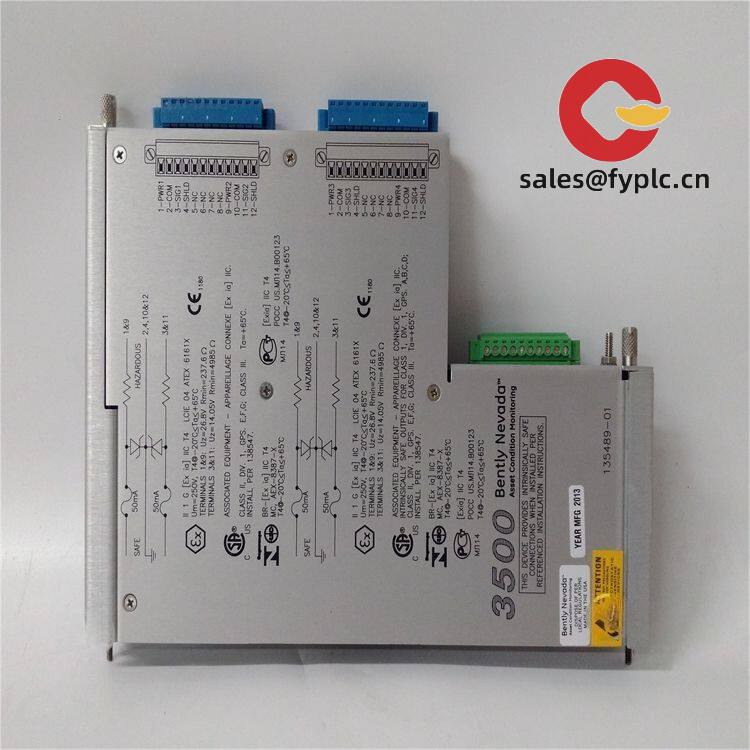

Bently Nevada 135489-01 I/O Module – Rear I/O termination for 3500 machinery protection racks

The Bently Nevada 135489-01 is a rear I/O module used with the 3500 series monitors to terminate field wiring, provide buffered outputs, and route status/alarm signals through the rack. From my experience, it’s the piece that makes on-skid wiring clean and reliable—especially when you need consistent terminations for proximity, seismic, and Keyphasor inputs with minimal downtime during maintenance.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express: FedEx, UPS, DHL

Key Features

- 3500 rack compatibility – Designed to mount on the rear of Bently Nevada 3500 racks, matching the associated front monitor.

- Clean field terminations – Screw/plug terminal connections for sensors and outputs simplify panel wiring and reduce commissioning time.

- Buffered outputs – You might notice that buffered BNC/terminal outputs (where applicable) make route-based data collection faster without disturbing protection logic.

- 4–20 mA proportional outputs – Typically available per channel on relevant monitor/I/O pairings for trending in DCS/PLC.

- Status/alarm routing – Passes OK, alert, and danger states through the rack so trips and events are handled consistently.

- Serviceability in the cabinet – Rear access form factor keeps front monitor access clear; technicians can isolate channels quickly during checks.

- Rugged design – Built for industrial panels; in many cases, it seems to be more tolerant to electrical noise than generic terminal solutions.

Technical Specifications

| Brand / Model | Bently Nevada 135489-01 I/O Module (for 3500 system) |

| HS Code | 9032.89 – Other automatic regulating or controlling instruments and apparatus |

| Power Requirements | Powered via 3500 rack backplane; no external power supply required |

| Operating Temperature | Typically -30 to +65 °C (3500 series environmental range) |

| Signal I/O Types | Field terminations for proximity/seismic/Keyphasor inputs (per paired monitor), buffered outputs, 4–20 mA proportional outputs (where applicable), relay interfacing via associated relay modules |

| Communication Interfaces | Onboard: none; rack-level comm via 3500/22M Communications Gateway or 3500/32M TDI |

| Installation Method | Rear-mounted I/O; occupies the rear slot directly behind its associated 3500 front monitor; pluggable/screw terminal wiring |

| Dimensions & Weight | Standard 3500 rear I/O form factor; depth approx. 240 mm; weight approx. 0.25–0.30 kg |

Application Fields

This I/O module is typically paired with 3500 monitors (e.g., Proximitor/Seismic, Keyphasor, Temperature) across:

- Oil & Gas – compressors, gas turbines, pumps, and expanders

- Power Generation – steam/gas turbines, generators, balance-of-plant assets

- Petrochemical & Chemical – process pumps and blowers

- Pulp & Paper, Mining, Water – large rotating machinery and critical fans

One thing I appreciate is how it keeps route-based data collection straightforward. A maintenance engineer told us they rely on the built-in buffered outputs to grab diagnostics without touching the protection settings—saves them a field trip or two every month.

Advantages & Value

- Reliability – Proven hardware ecosystem with consistent channel integrity and stable connections.

- Compatibility – Works within the 3500 platform; wiring layouts match standard Bently Nevada practices, reducing engineering time.

- Cost & time savings – Faster commissioning, fewer re-terminations, and ready access to buffered signals for diagnostics.

- Technical support – We help confirm monitor/I/O pairing and terminal maps before shipment to avoid panel rework.

Installation & Maintenance

- Cabinet & environment – Install in a clean, ventilated control cabinet; maintain ambient temperature within the typical 3500 range; avoid conductive dust and moisture.

- Mounting – Seat the 135489-01 into the rear slot directly behind the corresponding front monitor; tighten retention hardware evenly.

- Wiring – Use shielded, twisted pairs for transducer inputs; ground shields at one end; label channels clearly to match monitor configuration.

- Safety – De-energize wiring circuits before changes. ESD protection is recommended when handling modules. For hazardous areas, use only within the certified zone ratings of the complete 3500 assembly.

- Maintenance – Periodically check terminal tightness, clean dust with dry air, verify 4–20 mA scaling in the DCS, and keep rack firmware (TDI/22M) current as per site policy.

Quality & Certifications

- CE compliant; typically UL/cUL for control equipment; RoHS alignment for lead content

- Manufactured under ISO 9001 quality systems (manufacturer)

- Warranty: 365 days

Need help verifying that 135489-01 matches your specific 3500 monitor and terminal map? Send the front-module model (e.g., 3500/42M, 3500/40M) and we’ll confirm the exact I/O pairing before you place the order.

Reviews

There are no reviews yet.