Description

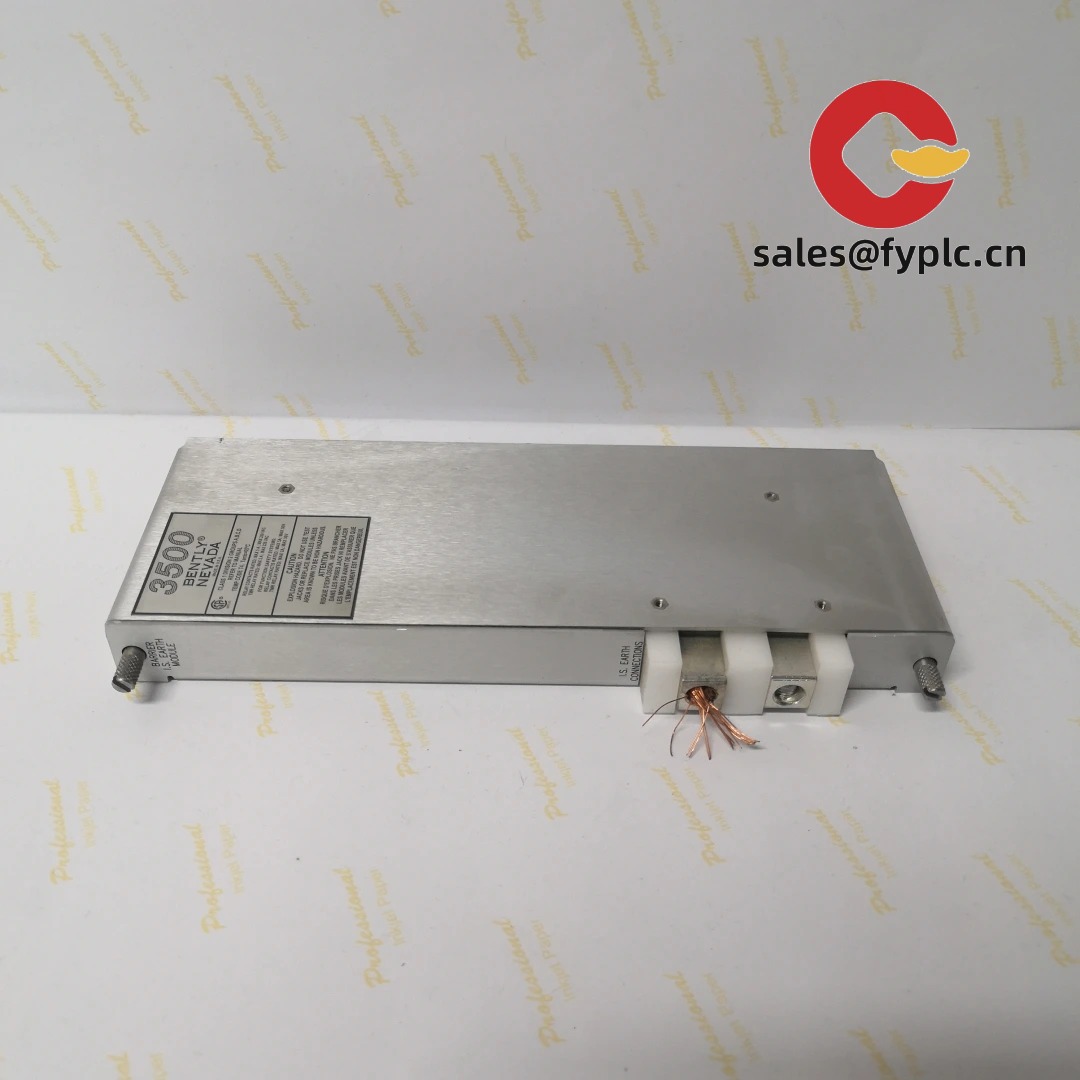

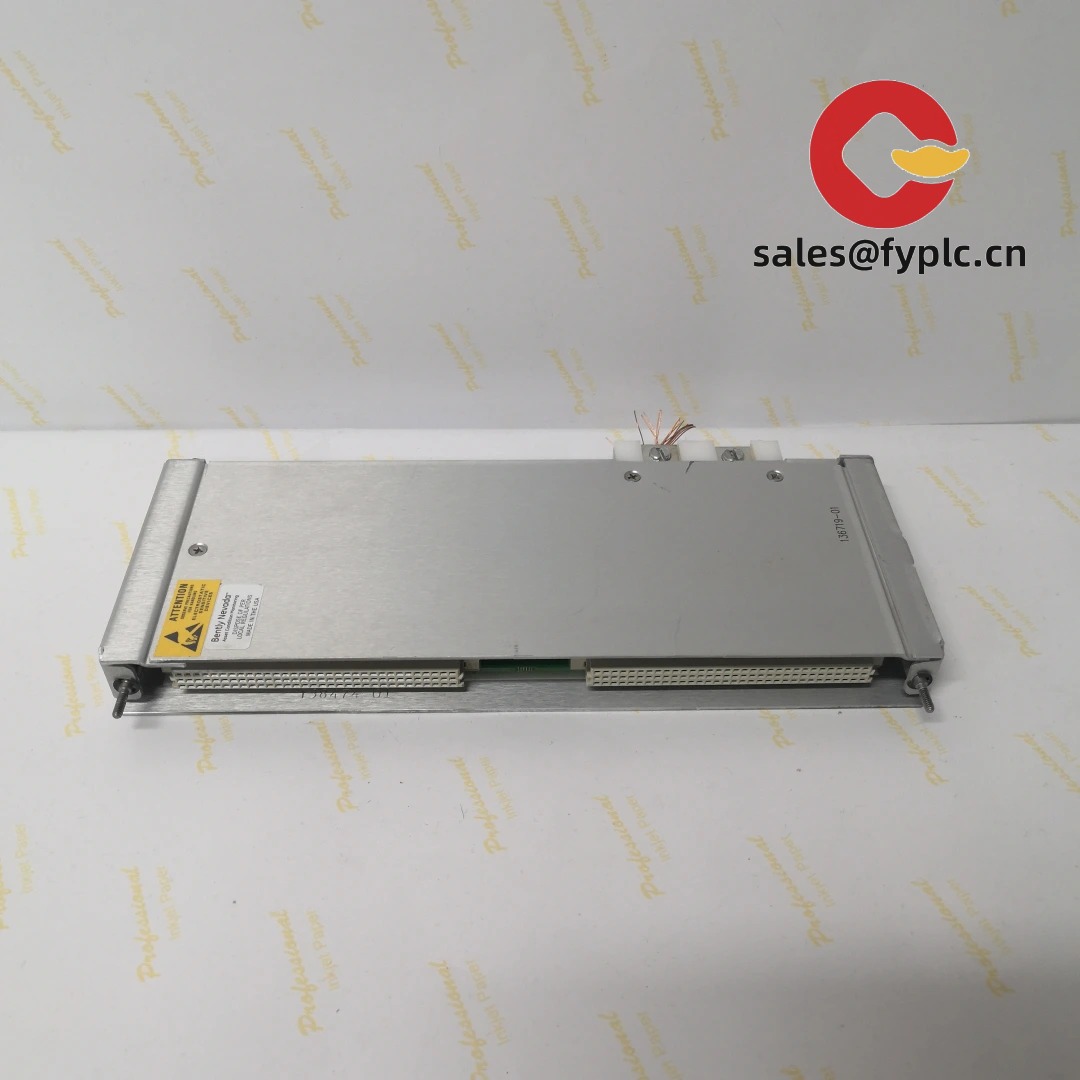

BENTLY NEVADA 136719-01 – Temperature Monitor Module for 3500 Series Machinery Protection

If you’re standardizing on the 3500 rack, the BENTLY NEVADA 136719-01 is a dependable temperature monitoring module for continuous machine protection and trending. From my experience, it slots straight into existing 3500 frames and works with your RTD or thermocouple sensors to raise timely alarms before heat-related faults escalate. You might notice that it integrates neatly with the 3500/22M TDI for data collection, so maintenance teams see the temperatures they care about inside the same platform they already trust.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Multi-sensor support: Accepts common RTD and thermocouple inputs, so you can reuse existing probes on pumps, compressors, and turbines.

- Continuous protection: Real-time monitoring with configurable alarms helps catch bearing heating, seal degradation, or process upsets early.

- 3500 rack integration: Powered by the 3500 backplane and communicates through the 3500/22M TDI—no extra network card on the module.

- Channel-level diagnostics: Sensor OK checking and channel status help distinguish wiring faults from genuine temperature events.

- Flexible configuration: Per‑channel input type selection, filtering, and alarm setpoints to match your plant standards.

- Service-friendly I/O: Rear I/O with removable terminals typically reduces downtime during probe replacement.

Technical Specifications

| Brand / Model | BENTLY NEVADA 136719-01 (3500 Series Temperature Monitor Module) |

| HS Code | 9032.89 (automatic regulating or controlling instruments, other) |

| Power Requirements | Supplied via 3500 rack backplane (with 3500/15 power supply); no external power to the module |

| Dimensions & Weight | Approx. 241 mm (D) × 25 mm (W) × 228 mm (H); ~0.5 kg typical 3500 monitor form factor |

| Operating Temperature | 0 to +65 °C (typical for 3500 monitors) |

| Signal Input Types | RTD (Pt100 / Pt1000, 2‑ or 3‑wire); Thermocouple (J, K, E, T, N, R, S, B), channel-selectable |

| Signal Output Types | Status and alarms via rack backplane; relay outputs handled by 3500 relay modules |

| Communication Interfaces | 3500 backplane to 3500/22M TDI (Ethernet access via TDI); local LEDs for channel status |

| Installation Method | Front-pluggable module with matching rear I/O; tool-free module insertion; field wiring on removable terminal blocks |

Application Fields

Typically used on bearing housings, motor windings, lube oil circuits, and seal areas where temperature rise is an early indicator of trouble. In refineries and petrochemical plants it seems to be a favorite for critical pumps and compressors. Power generation users often pair it with vibration monitors to protect steam and gas turbines. I’ve also seen it on paper machine dryer cans and large HVAC chillers where trending helps plan shutdown windows.

Advantages & Value

- Reliability: Designed for continuous duty in the 3500 platform—stable, predictable behavior under plant conditions.

- Compatibility: Works with standard RTD/TC types and the wider 3500 ecosystem (3500/22M TDI, 3500/33 Relay, 3500/15 Power Supply).

- Cost savings: Reuses existing sensors and wiring in many cases; reduces nuisance trips with proper OK checking and alarm filtering.

- Supportability: Configuration and diagnostics through familiar 3500 toolsets simplify commissioning and audits.

A maintenance lead at a fertilizer plant put it simply: “We added temperature channels on three hot-running pumps. The early warning averted two unplanned outages in the first quarter.”

Installation & Maintenance

- Panel & environment: Install in a standard 3500 rack within a clean, ventilated cabinet. Keep ambient within the specified range and allow airflow around the rack.

- Wiring: Use shielded cable for thermocouples; maintain proper polarity. For RTDs, match 2- or 3‑wire configuration and keep lead lengths consistent for accuracy.

- Grounding & noise: Single-point ground and correct shield termination reduce drift and spurious alarms.

- Safety: De-energize the rack slot before inserting or removing modules. Verify sensor circuits are de-energized in classified areas.

- Routine care: Periodically verify channel calibration against a known reference, clean terminals, check tightness, and review alarm setpoints during outages.

- Firmware/Config: Keep module configuration backed up; coordinate firmware compatibility with the 3500/22M TDI to avoid mismatches.

Quality & Certifications

- Manufactured to industrial quality standards; CE compliant

- Typically meets RoHS; UL/CSA certifications available on the 3500 platform

- Manufacturer warranty practices apply; our supply warranty is 365 days as stated above

One thing I appreciate is how seamlessly the 136719-01 drops into mixed racks—vibration on one slot, temperature on the next—so you can expand protection without redesigning the cabinet. If you’d like, we can also supply complementary modules such as 3500/22M TDI, 3500/33 Relay, and 3500/15 Power Supply to round out the build.

Reviews

There are no reviews yet.