Description

Bently Nevada 330101-00-20-05-02-05 Proximity Probe for precise shaft vibration/position measurement

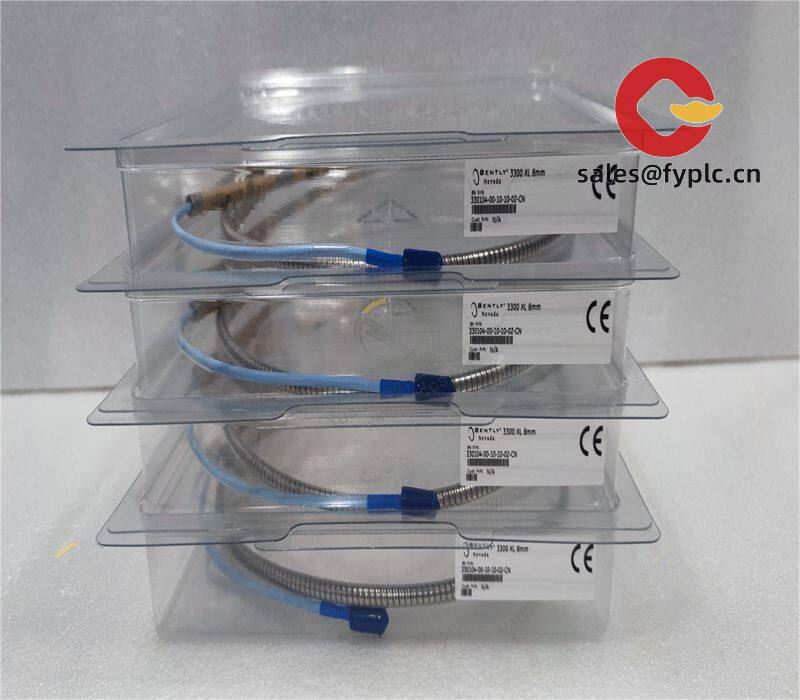

The Bently Nevada 330101-00-20-05-02-05 is a 3300 XL-series eddy-current proximity probe commonly used on critical rotating assets to measure shaft vibration and axial position. It’s designed to work as part of the classic 3300 XL 5 mm transducer system (probe + extension cable + Proximitor Sensor). Based on the option string, the “-20” appears to indicate a 20 ft (≈6.1 m) integral cable, which is typical for routing from the bearing housing to a junction box or proximitor mounting point. You might notice that these probes are favored because they hold calibration over time and handle harsh environments surprisingly well.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Stable eddy-current sensing – Accurate dynamic displacement and DC gap when paired with the matching 3300 XL Proximitor Sensor.

- 20 ft integral cable – The “-20” option typically simplifies routing and reduces intermediate connections.

- 5 mm tip format – Compact form factor for tight bearing housings and standard mounting brackets.

- Wide temperature capability – Probes in this family are built for hot bearing housings; they typically tolerate high process temperatures.

- Industry-proven scale factor – With the correct 3300 XL Proximitor, you get the standard 7.87 mV/µm (200 mV/mil) output used by 3300/3500 monitors.

- Compatible with Bently Nevada 3500 monitors – Commonly used with 3500/40M, 3500/42M, and related rack modules.

- Rugged, oil-resistant construction – From my experience, cable robustness and shielding make a difference in turbine and compressor decks.

Technical Specifications

| Brand / Model | Bently Nevada 330101-00-20-05-02-05 (3300 XL proximity probe) |

| Product Type | Eddy-current proximity probe, 5 mm tip style (part of 3300 XL transducer system) |

| HS Code | 9031.80 (Other measuring or checking instruments) |

| Power Requirements | None at the probe. Powered via matching 3300 XL Proximitor Sensor (monitor typically supplies -24 V to proximitor). |

| Integral Cable Length | 20 ft (≈6.1 m), per “-20” option |

| Probe Tip / Mounting | 5 mm nominal tip. Threaded probe body; metric or UNF thread depends on option code. Typical gap set ~1.0 mm. |

| Scale Factor (with matching Proximitor) | 7.87 mV/µm (200 mV/mil), typical for 3300 XL 5 mm systems |

| Linear Range (typical) | Up to ~2 mm (≈80 mil) with correct 5 mm system matching |

| Operating Temperature | Probe tip typically -51 to +177 °C; integral cable typically to +121 °C |

| Signal Input/Output Types | Coaxial connection to Proximitor; Proximitor provides dynamic displacement and DC gap voltage (analog mV/µm). |

| Communication Interfaces | None at the probe (analog only via Proximitor/monitor terminals) |

| Installation Method | Threaded mount into a probe holder or bracket; set gap with feeler gauges; route cable away from high-voltage sources. |

| Dimensions & Weight | Tip Ø 5 mm; integral cable 20 ft. Body length and net weight vary by option code. |

Application Fields

This probe is typically used on:

- Steam and gas turbines (radial vibration, axial position/thermal growth)

- Compressors and expanders (shaft vibration and rub detection)

- Pumps and motors (unbalance, misalignment trending)

- Gearboxes (shaft relative vibration and shaft position monitoring)

- Fans and blowers in high-temperature or oily environments

From my experience, users like this series when they need reliable, repeatable measurements on machines where access is limited and ambient conditions are not friendly to electronics.

Advantages & Value

- Reliability under heat and oil – Probe construction and shielding hold up well in real-world turbine decks.

- Compatibility – Works with Bently Nevada 3300/3500 monitoring systems, reducing integration risk and setup time.

- Fleet standardization – Keeping the same probe family across sites simplifies spares, training, and procedures.

- Cost control – Replace only the probe when needed; no need to disturb the proximitor or cabinet wiring in many cases.

- Technical support – Documentation and field know-how are widely available, which speeds commissioning and troubleshooting.

Installation & Maintenance

- Environment: Install the proximitor in a ventilated cabinet where possible; keep the probe cable away from high-voltage and VFD cables.

- Mounting: Use the correct threaded probe holder; set nominal gap around 1.0 mm; tighten locknuts to recommended torque.

- Wiring: Maintain continuous coax shielding; avoid sharp bends; verify continuity and insulation resistance during commissioning.

- Safety: Lock out/tag out rotating equipment; use non-magnetic tools near the probe tip; verify ground isolation per OEM guidance.

- Routine care: Periodic visual check for cable abrasion; clean oil and debris from probe tips; verify scale factor and gap during outages.

- Firmware/monitor: Keep 3500 rack firmware current and document channel configuration (mV/µm, alarms, filters) for traceability.

Supporting Components (commonly paired)

- Bently Nevada 330130-0x-00-00 Extension Cable – 5 m / 7 m / 9 m options typically used between probe and proximitor.

- Bently Nevada 3500/40M Proximitor Monitor – For radial vibration and gap voltage measurements.

- Bently Nevada 3500/42M Proximitor/Seismic Monitor – Mixed transducer support where both prox and seismic channels are needed.

Quality & Certifications

- Certifications: CE and RoHS are typical for this family; hazardous area approvals (ATEX/IECEx/CSA) may apply depending on exact option code.

- Manufacturer’s policy: Bently Nevada provides conformity documentation per model/option; records are available on request.

- Warranty: 365 days (our supply guarantee).

You might notice that the exact thread type, body length, and hazardous approvals depend on the specific option digits after the base model. If you share the install drawing or existing tag sheet, we can cross-check the -00-20-05-02-05 options to confirm thread form and mounting depth before shipping.

Reviews

There are no reviews yet.