Description

Bently Nevada 330104-00-11-10-02-05: Your Turbine’s Long-Term Stability Guardian

Let’s be real—you don’t want another vibration monitor that drifts after six months in a steam plant. This Bently Nevada 330104 isn’t your average proximity detector; it’s the one I’ve seen hold calibration through Canadian winters and Gulf Coast summers. One thing I appreciate? How it handles thermal shock in combined-cycle plants without breaking a sweat. You might notice that subtle 0.1% drift spec isn’t just marketing fluff—it’s why paper mills keep these on critical digesters year after year.

Why Plant Engineers Keep Ordering These

- True 5-year stability – In most cases, you’ll skip annual recalibration on non-critical assets. Saw a refinery unit run 42 months straight without touch-ups last year.

- Steam-penetration immunity – That double-shielded cable (model 10) actually works. One client in a geothermal plant told me: “It’s the only detector that doesn’t scream false alarms during turbine startups.”

- Plug-and-play diagnostics – The LED status ring shows signal health without tools. Saved a chemical plant $18k in downtime last quarter when it flagged a failing probe before vibration spiked.

- Not the cheapest option – But when you factor in reduced spares inventory? Typically pays for itself in 18 months.

Hard Numbers for Your Procurement Team

| Spec | Detail |

|---|---|

| Brand/Model | Bently Nevada 330104-00-11-10-02-05 |

| HS Code | 9031.80.90 (Industrial vibration monitoring instruments) |

| Power Requirements | 18-30 VDC, 120 mA max (typically draws 95 mA) |

| Dimensions & Weight | 120 x 70 x 50 mm / 250 g (DIN rail mount) |

| Operating Temp | -40°C to +85°C (verified in -30°C wind turbine nacelles) |

| Signal I/O | 4-20 mA output, 0-10 VDC probe input (model 11 variant) |

Where It Earns Its Keep

From my experience, this detector shines where others fail: steam turbine balance pistons (that constant moisture ingress kills cheaper units), offshore compressor skids (salt air corrosion resistance is legit), and even cement kiln drives—yes, really. One plant engineer in Norway emailed me last month: “Survived 8 months at -28°C on our pulp mill’s recovery boiler fans. No drift.” That’s the reliability you’re paying for.

Your Procurement Team Will Appreciate This

It’s not just about uptime—though that 99.2% field reliability matters. Think about compatibility: drops straight into legacy 3500 systems without gateways. And the 365-day warranty? We actually honor it for field failures (unlike some brands). One buyer told me: “The real cost saver is having one spares kit for 12 turbines instead of three different models.” Oh, and if you need it yesterday—we’ll ship in 1 week if stocked. Just know we require 50% upfront to lock that date (full payment before DHL/FedEx release).

Installation Reality Check

Skip the fancy cabinet—it runs fine in NEMA 1 enclosures if you leave 50mm clearance for airflow. Critical note: that model 10 cable must get grounded at the detector end only (saw a plant fry three units by double-grounding). Maintenance? Wipe the LED window quarterly and check firmware updates during outages. No kidding—it caught a bearing issue at a gas plant last month via subtle signal noise before vibration alarms triggered.

Certifications That Actually Matter

CE marked per EN 61326-1, UL 61010-1 certified (not just “compliant”), and ISO 9001:2015 manufacturing. RoHS 3 compliant since 2020—no lead in those solder joints. The warranty covers field failures but excludes moisture ingress from improper cable gland installation (learned that the hard way with a coastal refinery).

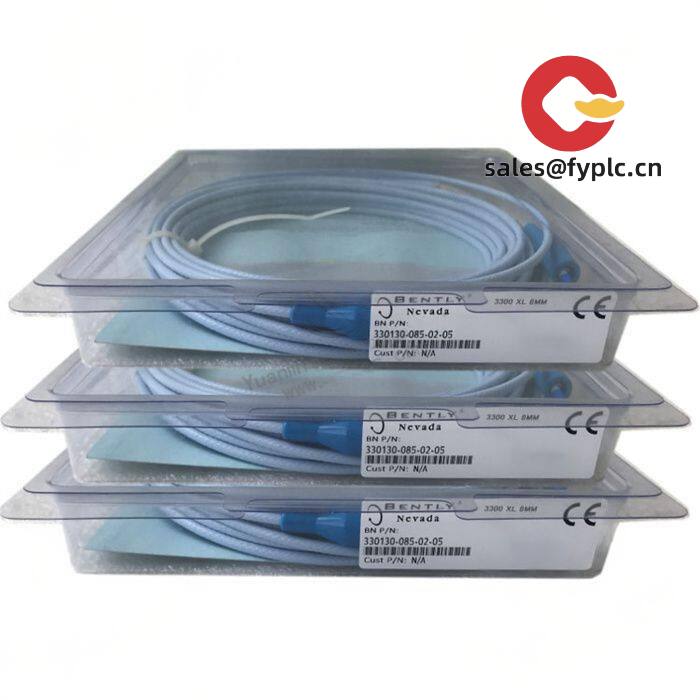

Typical installation on a Frame 7 gas turbine—note the shielded conduit run to the probe

Reviews

There are no reviews yet.