Description

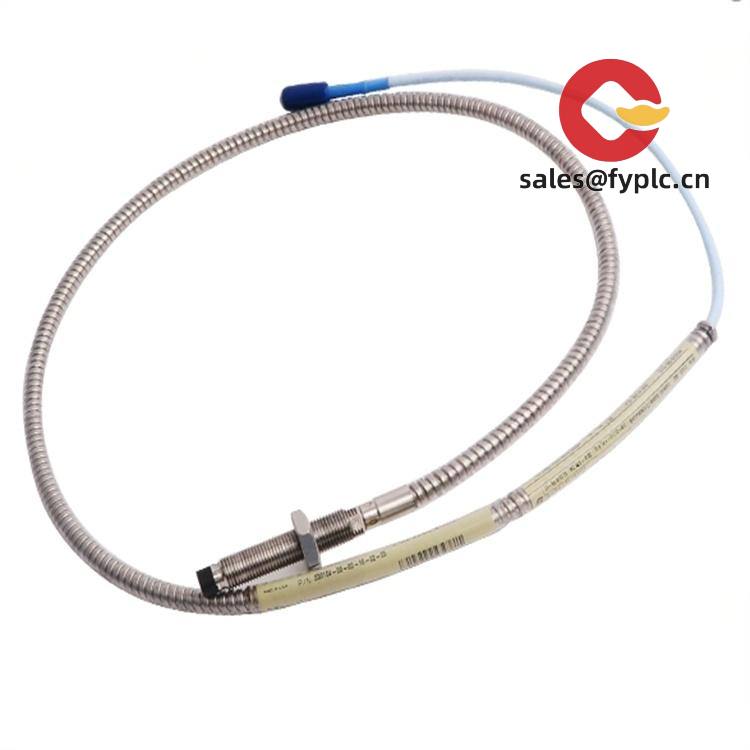

Bently Nevada 330104-05-11-10-02-CN – 8 mm Proximity Probe for 3300 XL Transducer Systems

The Bently Nevada 330104-05-11-10-02-CN is part of the 3300 XL proximity transducer system, designed for non-contact measurement of shaft vibration and axial position on critical rotating machinery. From my experience, this 8 mm probe is the go-to choice for steam turbines, compressors, and large motors where reliable dynamic signal pickup and stable gap control matter day in, day out. Pair it with a 3300 XL Proximitor sensor and an appropriate extension cable to build a complete transducer chain that ties directly into Bently Nevada 3500/3300 monitoring systems.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment, full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- 8 mm probe tip – A mainstream size for medium-to-large machinery, providing robust dynamic signal and dependable gap measurements.

- 5 m integral cable (code “05”) – Typically used to assemble 5 m systems or mixed-length systems depending on the extension cable chosen.

- 3300 XL system compatibility – Works with 3300 XL Proximitor sensors and Bently Nevada 3500/3300 monitors for direct shaft vibration and position inputs.

- Stable sensitivity – Standard 8 mm system sensitivity is typically 200 mV/mil (≈ 7.87 mV/µm) when used with matching Proximitor and extension cable.

- Industrial-grade temperature capability – Probe assembly is designed for harsh environments commonly found on hot-end turbomachinery.

- Threaded mounting with locknuts – Simple, repeatable installation; you might notice fewer re-gapping cycles after shutdowns when the mount is done right.

- Backwards-fit with installed bases – In many cases, this model drops into existing 3300 XL setups without changing monitors or software.

Technical Specifications

| Brand / Model | Bently Nevada 330104-05-11-10-02-CN (8 mm proximity probe) |

| HS Code | 903180 (Measuring/monitoring instruments, other) |

| Power Requirements | Supplied via matching 3300 XL Proximitor sensor (–24 Vdc nominal from the monitoring system) |

| Sensitivity (system) | Typically 200 mV/mil (≈ 7.87 mV/µm) with the correct Proximitor and extension cable |

| Linear Range (system) | Typically up to 80 mils (≈ 2.0 mm) for 8 mm systems on steel targets |

| Operating Temperature | Probe: typically –35°C to +177°C; Proximitor (for reference): typically –35°C to +65°C |

| Dimensions & Weight | 8 mm tip diameter; integral cable length 5 m (code “05”). Weight varies with cable routing; contact for exact figure. |

| Signal I/O Types | Eddy-current probe input to Proximitor; gap (DC) and dynamic vibration (AC) outputs from Proximitor to monitor |

| Communication Interfaces | Not applicable (analog transducer system) |

| Installation Method | Threaded probe mount with locknuts; Proximitor typically mounted on panel or DIN rail; gapping via feeler gauges/target |

| Thread / Tip | 8 mm tip; thread per model code. This variant commonly uses a standard threaded sleeve for machine brackets. |

| System Compatibility | 3300 XL Proximitor sensors (e.g., matching 8 mm units) and Bently Nevada 3500/3300 monitoring systems |

Application Fields

You’ll typically see the 330104 used on:

- Steam and gas turbines – radial vibration, axial position, and differential expansion points

- Compressors and expanders – rotor dynamics and machine protection

- Large induction motors and generators – bearing vibration and shaft position trending

- Gearboxes and fans – coupling monitoring and early fault detection

Advantages & Value

- Reliability – The 3300 XL family is known for long service life; fewer nuisance alarms when the system is matched correctly.

- Compatibility – Seamless fit with installed Bently Nevada racks, which usually cuts commissioning time.

- Lifecycle cost – Stable calibration means less frequent rework; spare parts are straightforward to stock across units.

- Technical support – Clear selection between probe, extension cable, and Proximitor reduces mix-ups. We can help cross-check your cable lengths and thread options before shipment.

One thing I appreciate is how predictable the gap and dynamic response are when the system uses the correct combination: 330104 probe + matching 3300 XL Proximitor + the right-length 330130 extension cable. A maintenance lead recently shared that swapping to matched 5 m systems eliminated a persistent drift issue on a hot compressor train.

Installation & Maintenance

- Mounting – Install the probe in a rigid, properly threaded bracket; locknuts should be snug but not over-torqued. Maintain orthogonal orientation to the shaft target.

- Gapping – Set the probe-to-target gap per system guidelines (typically mid-range of linear region). Verify gap voltage at the monitor after thermal stabilization.

- Cabling – Route cables away from high-voltage conductors and VFD outputs. Avoid tight bends; use protective conduit in high-traffic areas.

- Cabinet & ventilation – Mount Proximitor sensors in a clean enclosure with adequate ventilation; follow IP rating and temperature limits.

- Safety – Lock out machinery during installation; confirm no contact between probe tip and rotating surfaces.

- Routine maintenance – Inspect probe tip cleanliness during outages, confirm gap voltage, and check connectors. Firmware updates are not applicable to the probe, but it’s good practice to keep your monitor firmware current.

Quality & Certifications

- CE conformity

- RoHS compliance

- UL/CSA recognition (varies by subcomponent and region)

- Manufacturer’s standard quality system (ISO-based)

- Warranty: 365 days

Commonly Paired Components (for a complete system)

- Bently Nevada 330130 – 3300 XL extension cable (length to match probe for total system length)

- Bently Nevada 3300 XL Proximitor Sensor – matching 8 mm unit for the 330104 probe

- Bently Nevada 3500 or 3300 series monitors – machine protection and condition monitoring

Note: The code string “-05-11-10-02-CN” defines specific options (such as cable length and mechanical details). If you’re replacing an installed probe, sharing your existing code helps ensure a perfect match.

Reviews

There are no reviews yet.