Description

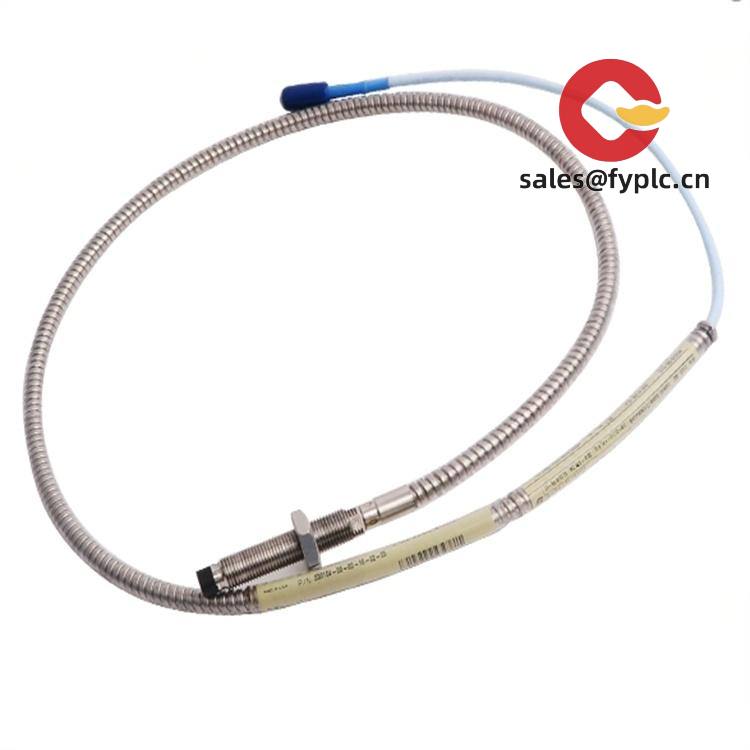

Bently Nevada 330104-11-22-10-02-CN – 3300 XL 5 mm Proximity Probe for Vibration and Shaft Position Monitoring

The Bently Nevada 330104-11-22-10-02-CN is part of the 3300 XL Proximity Transducer System. It’s the compact 5 mm proximity probe that pairs with an extension cable and a 3300 XL Proximitor Sensor to deliver API 670–class vibration, shaft position, and thrust measurements. From my experience, the 5 mm form factor is ideal when you’re tight on space around bearings or seals but still need the full linear range and sensitivity typically expected from a Bently Nevada system. The “-CN” suffix usually indicates a China-market documentation/marking variant; performance and function remain the same in most cases.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- 5 mm compact probe – Fits constrained mounting locations while maintaining a wide linear range for precise shaft gap and vibration.

- 3300 XL system compatibility – Designed to work with 3300 XL extension cables and Proximitor Sensors for a complete proximity transducer system.

- API 670 style performance – Sensitivity typically around -200 mV/mil (-7.87 mV/µm) with excellent linearity when used with the matched driver.

- Rugged, field-proven construction – Withstands harsh rotating machinery environments; shielding and robust cable help reduce electrical noise.

- Flexible system lengths – Probe + extension cable combinations typically available in 5 m, 7 m, or 9 m system lengths to match site standards.

- Common thread options – Often supplied with M8 × 1 mounting (other thread options exist by code), easing retrofit work.

Technical Specifications

| Brand / Model | Bently Nevada 330104-11-22-10-02-CN (3300 XL 5 mm Proximity Probe) |

| HS Code | 9031.80 (Measuring or checking instruments, other) |

| Power Requirements | Via 3300 XL Proximitor Sensor: 24 Vdc nominal, ~35 mA typical (driver powered; probe itself passive) |

| Operating Temperature | Probe: typically -51 to +177 °C; Proximitor: typically -35 to +85 °C |

| Signal I/O Types | Input: Eddy-current probe signal; Output (from Proximitor): DC gap + dynamic vibration, approx. -200 mV/mil (-7.87 mV/µm) |

| Communication Interfaces | Analog only (no digital comms) |

| Dimensions & Weight | 5 mm tip; probe length and cable length per order code; driver module dimensions typical of 3300 XL Proximitor form factor; weight varies by cable length |

| Installation Method | Threaded probe mount (commonly M8 × 1), locknut and sleeve; extension cable to 3300 XL Proximitor Sensor; driver bulkhead/DIN options |

| Typical System Lengths | 5 m, 7 m, or 9 m (probe + extension cable) |

| Compliance | API 670 style performance when paired with matching 3300 XL components |

Application Fields

You’ll typically see the 330104 used on critical rotating assets where space is restricted:

- Steam and gas turbines – radial vibration and differential expansion (with appropriate mounting)

- Compressors and expanders – shaft vibration and axial position (thrust) monitoring

- Pumps and fans – bearing housing vibration in compact housings

- Gearboxes – shaft relative vibration and runout measurement

- Motors and generators – shaft position and vibration in tight end-bell areas

Advantages & Value

- Proven reliability – The 3300 XL family is widely deployed; spare parts and know-how are easy to source.

- Form-factor flexibility – 5 mm probe lets you instrument locations where an 8 mm probe won’t fit, without sacrificing linear range in most cases.

- Compatibility – Works with 3300 XL Proximitor Sensors and integrates cleanly with Bently Nevada 3500/3701 series monitors.

- Lifecycle cost – Fewer nuisance trips thanks to stable sensitivity and good immunity to electrical noise means lower downtime costs long term.

- Quality control – Tight manufacturing tolerances help maintain channel-to-channel consistency, which makes multi-point balancing easier.

Installation & Maintenance

One thing I appreciate is how predictable the setup is when you follow API 670 practices. Typical gap is set around 1.0 mm (40 mil) on steel targets. You might notice that careful cable routing pays off—keep probe/extension cables away from high-voltage runs and use proper shielding termination at the Proximitor.

- Mounting – Thread the probe into the sleeve or bracket (commonly M8 × 1), lock it with the nut, and verify the linear range with a calibrated target.

- Environment – Install the Proximitor in a ventilated cabinet or protected enclosure; avoid condensation and direct heat sources.

- Wiring – Use the specified 3300 XL extension cable; do not mix lengths beyond the designated system length. Verify continuity and shielding.

- Safety – De-energize the cabinet before wiring; confirm hazardous area approvals for your site if required.

- Routine checks – Periodically confirm gap voltage, inspect connectors for corrosion, clean probe tips if buildup occurs, and document baseline vibration spectra for comparison.

Quality & Certifications

- CE and RoHS compliant (typical for 3300 XL family)

- UL/CSA recognition on associated drivers and assemblies, where applicable

- Designed to meet API 670 performance requirements when used as a complete system

- Manufacturer’s warranty: 365 days (our supply terms)

Related and Supporting Components

- Bently Nevada 3300 XL Proximitor Sensor (5 mm/8 mm compatible driver)

- Bently Nevada 330130 series Extension Cables (typical system lengths 5 m / 7 m / 9 m)

- Bently Nevada 330103 (8 mm probe) – alternative when more robust tip or different mounting thread is preferred

- Mounting sleeves, locknuts, and armor options for cable protection

Field feedback

“We swapped to the 330104 5 mm probes on a split-case pump where space was tight. Signal quality stayed consistent, and we matched the 7 m system length to the existing proximitor without reengineering the cabinet. Trip levels lined up with our API 670 settings with minimal re-tuning.”

Reviews

There are no reviews yet.