Description

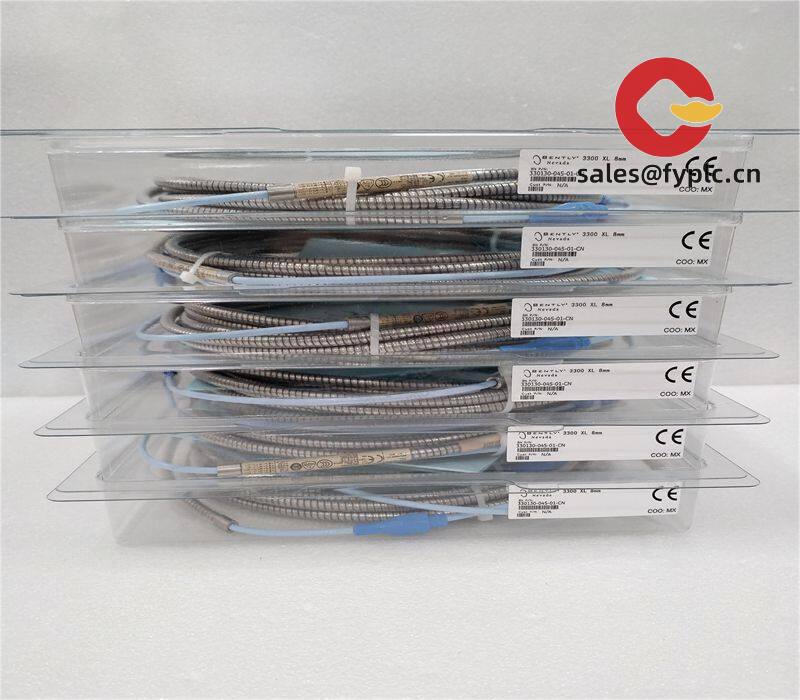

Bently Nevada 330106-05-30-10-02-CN Reverse-Mount Flexible Proximity Probe for Vibration and Shaft Position

The Bently Nevada 330106-05-30-10-02-CN is a reverse‑mount, flexible proximity probe designed for tight spaces and high-reliability condition monitoring. It integrates into the 3300 series proximity measurement system for accurate shaft vibration, axial position, and clearance (gap) measurements on rotating machinery. One thing I appreciate is how the reverse-mount format simplifies installation from the inside of a machine case, especially where traditional forward‑mount probes are hard to access.

The “-30” code typically indicates a 30‑ft (≈9.1 m) integral cable, which is a common length in refineries and power plants. The “CN” suffix, in many cases, denotes a regional variant (often packaging or documentation) with the same sensing performance. From my experience, this model pairs cleanly with 3300 series Proximitor sensors and 330130 extension cables to deliver the standard 200 mV/mil scaling engineers expect.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock items; no more than one month at the latest

- Payment method: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Reverse‑mount design – Installs from inside the machine case, ideal where external access is limited or where protection from external damage is needed.

- Flexible integral cable – The -30 code indicates long-reach cabling (approx. 30 ft), helpful for routing through crowded cabinets or long conduit runs.

- Non‑contact eddy‑current sensing – Stable shaft vibration/position measurements on conductive targets, typically steel shaft journals.

- System compatibility – Designed to work with 3300 series Proximitor sensors and 330130 extension cables for standard scale factors (often 200 mV/mil / 7.87 mV/µm).

- Industrial durability – Rugged probe construction for turbines, compressors, and pumps where high temperatures and vibration are routine.

- API 670 style practices – Supports typical machine protection architectures used across oil & gas, petrochem, and power generation.

Technical Specifications

| Brand / Model | Bently Nevada 330106-05-30-10-02-CN (Reverse‑mount, flexible proximity probe) |

| HS Code | 9031.80 (Measuring or checking instruments, other) |

| Power Requirements | Probe is passive; powered via compatible 3300 series Proximitor sensor (driver) |

| Signal I/O | Non‑contact eddy‑current input to metallic target; Proximitor output is voltage proportional to gap/vibration (typically 200 mV/mil / 7.87 mV/µm with matched components) |

| Integral Cable Length | Approx. 30 ft (≈9.1 m), per “-30” length code |

| Operating Temperature | Probe components are typically rated for elevated industrial temperatures; consult exact datasheet for the installed variant. Many 3300‑series probes operate in the range around -51 to +121/177 °C depending on tip/cable. |

| Communication Interfaces | N/A (analog eddy‑current measurement chain via Proximitor) |

| Installation Method | Reverse‑mount threaded bushing with locknut; set gap to spec and route cable to Proximitor/extension cable |

| Dimensions & Weight | Reverse‑mount probe tip; weight varies with cable length (typically light, manageable for panel routing) |

Application Fields

This probe is used on medium to large rotating assets where continuous condition monitoring matters:

- Steam and gas turbines – shaft vibration and axial position (thrust) measurements

- Compressors and expanders – radial vibration monitoring for protection systems

- Pumps and fans – bearing housing and shaft dynamic behavior

- Generators and motors – runout, eccentricity, and relative shaft movement

- Petrochemical and refinery trains – API 670 machine protection architectures

A maintenance lead from a combined-cycle plant told us this reverse‑mount format “saved hours during outages” because the probe could be serviced from the bearing housing interior without disassembling nearby pipework. That seems to be a common theme on compact, higher‑speed compressors too.

Advantages & Value

- Reliability in harsh service – Designed for elevated temperature and vibration; stable readings over long cable runs.

- Full ecosystem compatibility – Works with established 3300 series drivers and extension cables, reducing integration risk.

- Lifecycle efficiency – Reverse‑mount often cuts downtime for adjustments, which typically translates into real maintenance savings.

- Traceable performance – Standard mV/mil scaling with matched components helps with cross‑site configuration consistency.

- Procurement confidence – Widely adopted in API 670 environments; parts support and field familiarity are strong.

Compatible Accessories & System Components

- Bently Nevada 3300 series Proximitor sensor – Drives the probe and provides the conditioned voltage output used by monitoring racks or PLCs.

- Bently Nevada 330130 Extension Cable – Common extension cable used to reach the Proximitor in the control panel while maintaining calibrated system length.

- Monitoring hardware – Compatible with Bently Nevada monitoring systems (e.g., machine protection racks) that accept standard 200 mV/mil inputs.

Installation & Maintenance

- Mounting – Install via the reverse‑mount bushing; tighten the locknut to manufacturer torque. Ensure correct probe target material (typically steel) and adequate target area.

- Gap setting – Set the static gap per system spec (commonly around 1.0–2.0 mm for 8 mm systems). Verify with a voltmeter at the Proximitor output during setup.

- Cable routing – Route away from high‑voltage noise sources; observe bend radius and avoid sharp edges. Use conduit or armor where needed.

- Cabinet environment – House Proximitor/monitoring electronics in a ventilated control cabinet; maintain clean, dry conditions.

- Safety – Lockout/tagout rotating equipment before any probe work. Confirm no rub/strike risk at full rotor growth.

- Routine maintenance – Periodic visual checks for cable abrasion, connector integrity, and secure mounting. Functional checks and calibration verification during outages are typically sufficient.

- Firmware/recordkeeping – Update monitoring system firmware when applicable and record probe system length and scale factors in the asset file.

Quality & Certifications

- Manufacturer quality systems typically align with ISO standards for industrial sensors.

- CE and RoHS compliance are commonly available for Bently Nevada proximity components used in industrial environments.

- Warranty: 365 days (provided by our sales channel as stated above).

If you need confirmation on the exact temperature class or thread/bushing details for 330106-05-30-10-02-CN, share your machine drawing or existing part code—we’ll match the probe and total system length so your scale factor stays within spec.

Reviews

There are no reviews yet.