Description

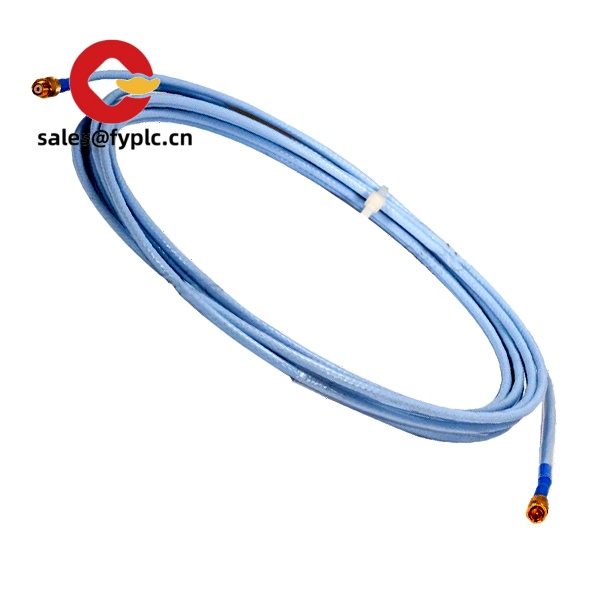

Bently Nevada 330130-040-02-00 – 40 ft Extension Cable for 3300 XL Proximity Transducer Systems

The Bently Nevada 330130-040-02-00 is a 40 ft (12.2 m) extension cable used to connect a 3300 XL proximity probe to its Proximitor sensor. From my experience, this cable is the “quiet link” in the chain—its shielding and connector design help preserve the tiny eddy-current signals that drive accurate vibration and shaft position measurements on turbines, compressors, and critical rotating assets. You might notice that it drops into existing 3300 XL installations without surprises, which is exactly what maintenance teams want when the clock is ticking.

Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: typically 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- 40 ft (12.2 m) factory-terminated cable – Sized for common machine-train layouts, reducing splices and noise pickup.

- Designed for 3300 XL proximity systems – Ensures signal integrity between probe and Proximitor sensor.

- ClickLoc-style coaxial connectors – Self-locking design typically resists loosening under vibration.

- Robust shielding – Helps maintain low-noise, low-drift measurements over longer runs.

- Ruggedized construction – Built for industrial environments around steam and gas turbines, compressors, and large motors.

- Consistent calibration chain – Keeps transducer system scaling intact when replacing like-for-like cables.

Technical Specifications

| Brand / Model | Bently Nevada 330130-040-02-00 |

| HS Code | 8544.42 (electrical conductors, voltage ≤1000V, fitted with connectors) |

| Power Requirements | Not applicable (passive extension cable) |

| Length | 40 ft (12.2 m) |

| Operating Temperature | Typically -46 to +80°C (-51 to +176°F), depending on cable jacket option |

| Signal I/O Type | Low-level eddy-current probe signal (probe-to-Proximitor connection) |

| Communication Interfaces | None (analog sensor extension cable) |

| Connectors | Coaxial, self-locking style (ClickLoc-type), factory-terminated |

| Installation Method | Routed in cable trays/conduit, connects between 3300 XL probe and Proximitor sensor |

Application Fields

Typically used wherever the 3300 XL proximity transducer system is installed:

- Steam and gas turbines (bearing and thrust position monitoring)

- Centrifugal and reciprocating compressors (radial vibration and rod drop)

- Large motors, generators, and gearboxes (shaft vibration/position)

- API 670-compliant protection systems and condition monitoring racks

“We swapped to 330130-040-02-00 cables during a 48-hour outage. The readings stabilized immediately, and our proximity channels stopped drifting. No rework needed.” — Maintenance supervisor at a combined-cycle plant

Advantages & Value

- Assured compatibility – Built for 3300 XL systems, reducing troubleshooting time after installation.

- Signal reliability – Shielding and connector design help cut noise pickup on longer runs.

- Lower lifecycle cost – Fewer nuisance alarms and less time chasing intermittent faults.

- Procurement confidence – Stable item code with consistent quality across batches.

- Support-ready – Documentation and application guidance available for common machine layouts.

Installation & Maintenance

- Environment – Route in trays or metallic conduit where possible; avoid hot surfaces and aggressive chemicals.

- Separation – Keep sensor cabling away from high-voltage/motor power cables to minimize EMI.

- Bend radius – Use gentle sweeps and avoid tight bends or repeated flexing; secure at intervals to prevent vibration fretting.

- Connectors – Hand-tighten self-locking connectors until seated; do not over-torque. Keep mating faces clean and dry.

- Grounding – Follow Bently Nevada grounding/shielding practices for the 3300 XL system to preserve measurement fidelity.

- Routine checks – Inspect routing and strain relief during outages; verify channel stability after any cable replacement.

Quality & Certifications

- CE and RoHS compliance for typical Bently Nevada transducer assemblies

- Manufactured under ISO 9001 quality systems (manufacturer-level)

- Manufacturer’s warranty is typically 1 year; sales warranty provided: 365 days

Reviews

There are no reviews yet.