Description

Bently Nevada 3500-05-01-03-00-00-00-1 — Dual-Channel Monitor Module for Critical Machinery Protection

Let’s cut to the chase: this isn’t just another rack-mounted monitor — it’s the backbone of many turbine, compressor, and large motor protection systems you’ll find in refineries, power plants, and LNG terminals. From my experience supporting field engineers over the past decade, the 3500-05 is one of those modules people quietly rely on — not flashy, but rarely replaced unless upgraded. It’s built to sit in a 3500 rack, continuously watching vibration, speed, and position signals — and tripping machinery *before* catastrophic failure happens.

Key Features

- Dual independent monitoring channels — Each channel handles its own sensor input (e.g., proximity probes or accelerometers), with separate alarm and danger thresholds. You might notice that this redundancy helps avoid single-point failures during calibration or probe drift.

- Configurable via 3500 Rack Manager or System 1 software — No need for a laptop at the cabinet every time. In most cases, changes can be pushed remotely — though I’d still recommend verifying logic in situ before startup.

- Real-time status LEDs + relay outputs — Four front-panel LEDs show OK, Alarm, Danger, and Fault states per channel. Two Form-C relays per channel let you interface directly with emergency shutdown (ESD) systems — no extra signal conditioning required.

- Hot-swappable design — Pull it out and swap it mid-run without powering down the entire rack. One thing I appreciate is how cleanly the module reboots and resynchronizes — typically under 8 seconds.

Technical Specifications

| Parameter | Specification |

|---|---|

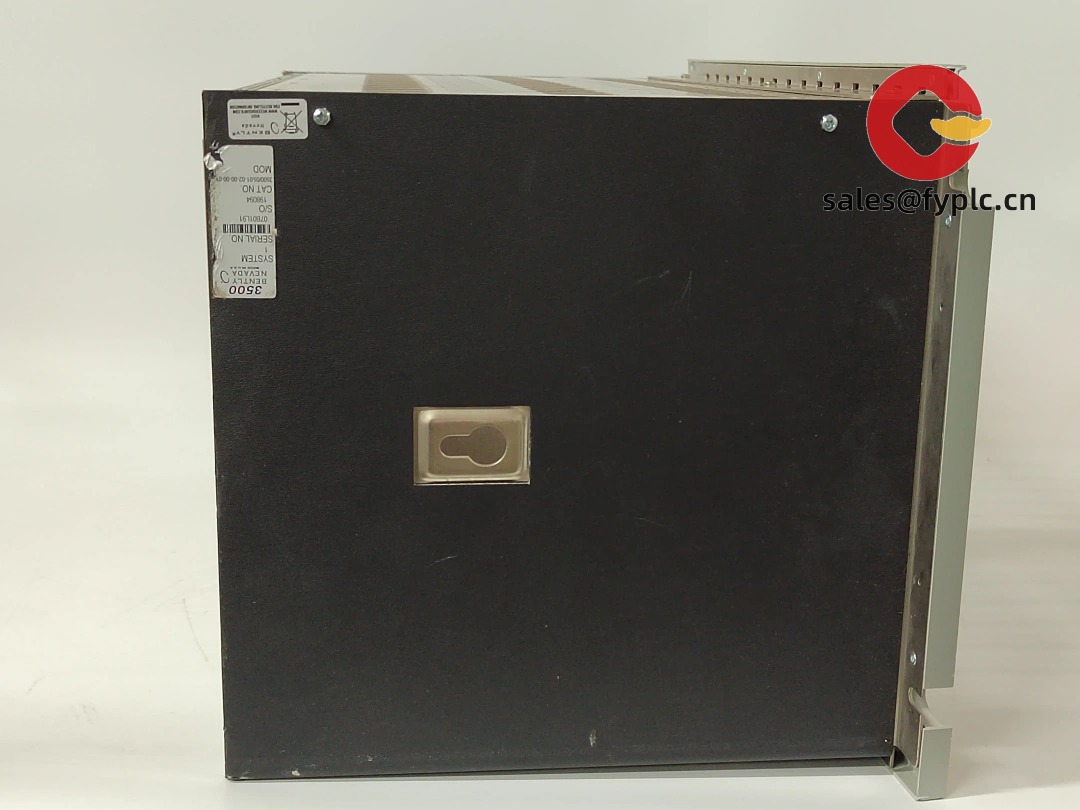

| Brand / Model | Bently Nevada 3500-05-01-03-00-00-00-1 |

| HS Code | 8531.80.90 (Monitoring & control instruments for industrial processes) |

| Power Requirements | +24 VDC nominal (±10%), supplied from 3500 rack backplane; typical draw: 180 mA |

| Dimensions & Weight | 21.6 cm H × 11.4 cm W × 24.1 cm D (8.5″ × 4.5″ × 9.5″); ~1.2 kg |

| Operating Temperature | 0 °C to +60 °C (derated above 50 °C) |

| Signal Input Types | Two channels, each accepting: proximity probe (–24 VDC bias), velocity (AC-coupled), or accelerometer (IEPE) inputs |

| Signal Output Types | 4 isolated relay outputs (2 per channel); 4–20 mA output optional via 3500-22 or 3500-25 modules |

| Communication Interfaces | RS-485 (Modbus RTU) to rack supervisor; Ethernet via 3500/22 or 3500/25 gateway modules |

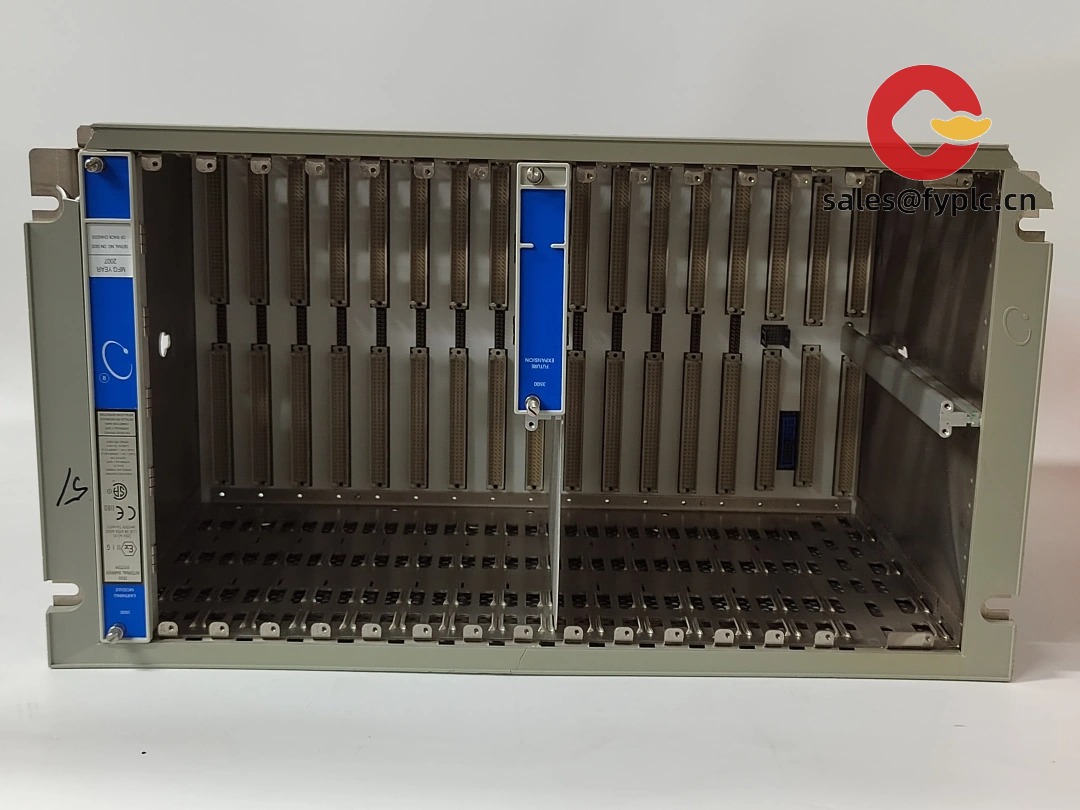

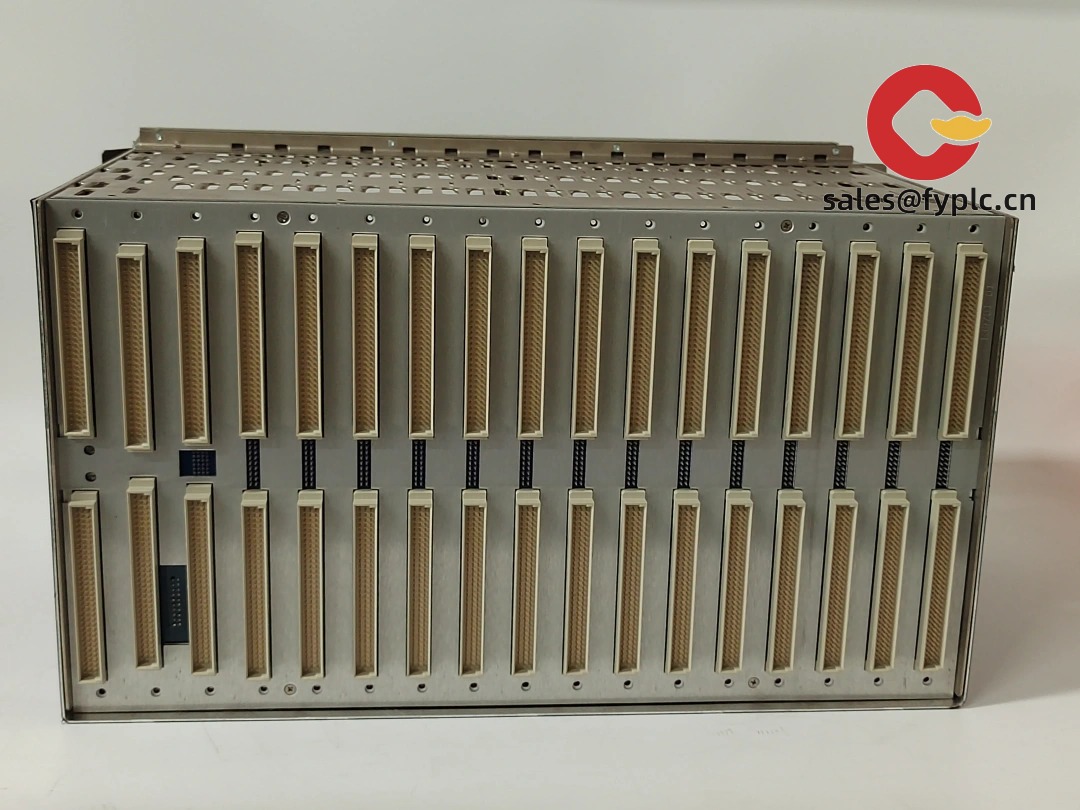

| Installation Method | Mounts into standard Bently Nevada 3500 rack (3500/15, 3500/20, etc.); requires rack power and supervisor module |

Application Fields

This module shows up where uptime isn’t just preferred — it’s contractual. Think steam turbines in combined-cycle power plants, centrifugal compressors in ethylene crackers, or critical feedwater pumps in nuclear support systems. A refinery client once told me they’d lost $2.3M in downtime during a single unplanned trip — and after installing dual 3500-05s with staggered alarm setpoints, their forced outage rate dropped by 68% over 18 months. It’s also used in offshore platforms, where environmental harshness demands proven reliability over novelty.

Advantages & Value

If you’re evaluating this for procurement, here’s what stands out: First, compatibility is baked in — no custom firmware or gateways needed to talk to legacy 3500 racks or newer System 1 deployments. Second, spare parts availability remains strong (unlike some discontinued 177x-series modules). Third, while not the lowest-cost option on paper, the TCO tends to be lower over 5+ years — fewer false trips mean less diagnostic labor, and fewer hardware swaps mean less engineering change control overhead. And yes — it supports partial stroke testing (PST) when configured with appropriate relays and timing logic.

Installation & Maintenance

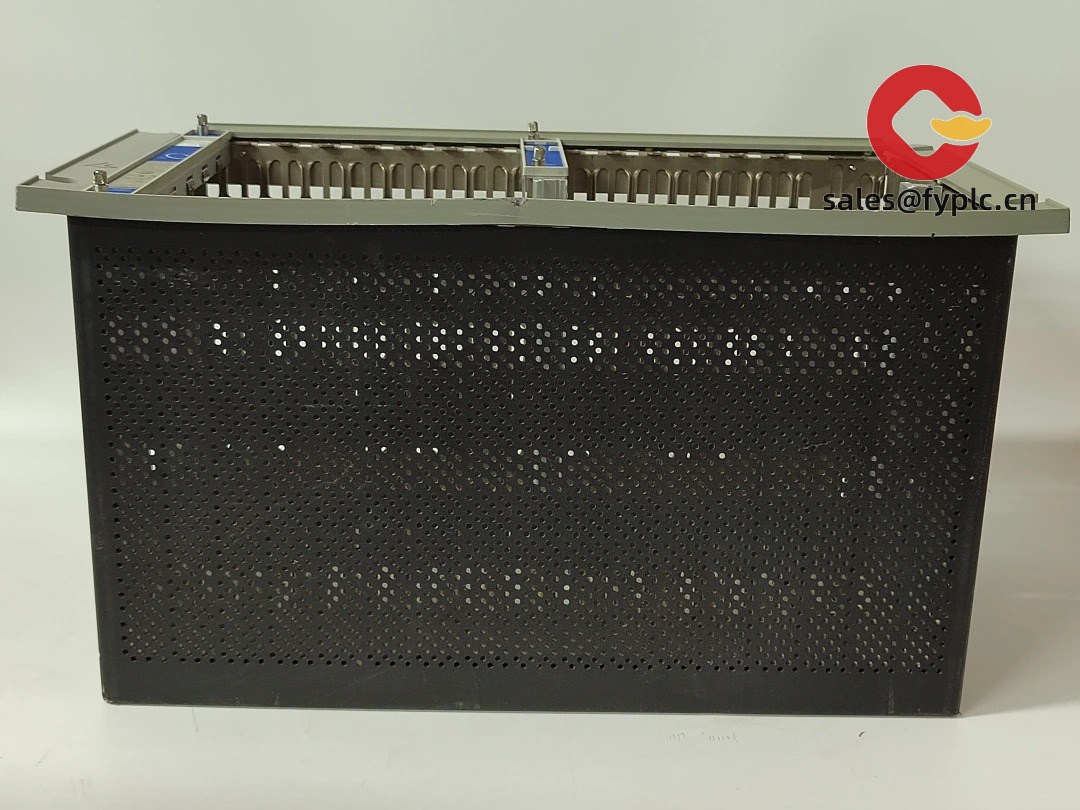

Install only in a NEMA 12 or IP54-rated cabinet with forced-air ventilation — ambient airflow should exceed 0.5 m³/min near the rack. Keep cable runs for proximity probes under 300 m (shielded twisted pair, 100 Ω impedance), and always ground shields at the rack end only. For safety: de-energize the rack supervisor before inserting or removing the module, even though it’s hot-swap capable. Routine maintenance? Check relay contact resistance annually (should be < 50 mΩ), clean dust filters every 6 months, and verify calibration against a known reference source every 12–18 months. Firmware updates are rare — the current version (v6.22) has been stable since 2021, and GE/Baker Hughes hasn’t issued a mandatory update for this model since then.

Quality & Certifications

Certified to UL 61010-1 (2nd Ed.), CE (EMC & LVD directives), ATEX II 2G Ex ib IIC T4 Gb (for use in Zone 1 hazardous areas), and RoHS 3 compliant. Backed by a full 365-day warranty — covering both parts and labor if installed per GE’s published guidelines. Note: This doesn’t include sensor calibration services or System 1 license renewals, which are handled separately.

Our Order Placement Process & Guarantees:

• Warranty: 365 days from date of shipment

• Delivery: 1 week for in-stock units (we keep 3500-05 variants in active rotation)

• Lead time: Up to 4 weeks maximum if requiring factory rebuild or special configuration

• Payment: 50% advance, balance prior to dispatch

• Shipping: Fedex, UPS, or DHL — fully tracked, with customs documentation pre-filled (including HS code 8531.80.90)

Reviews

There are no reviews yet.