Description

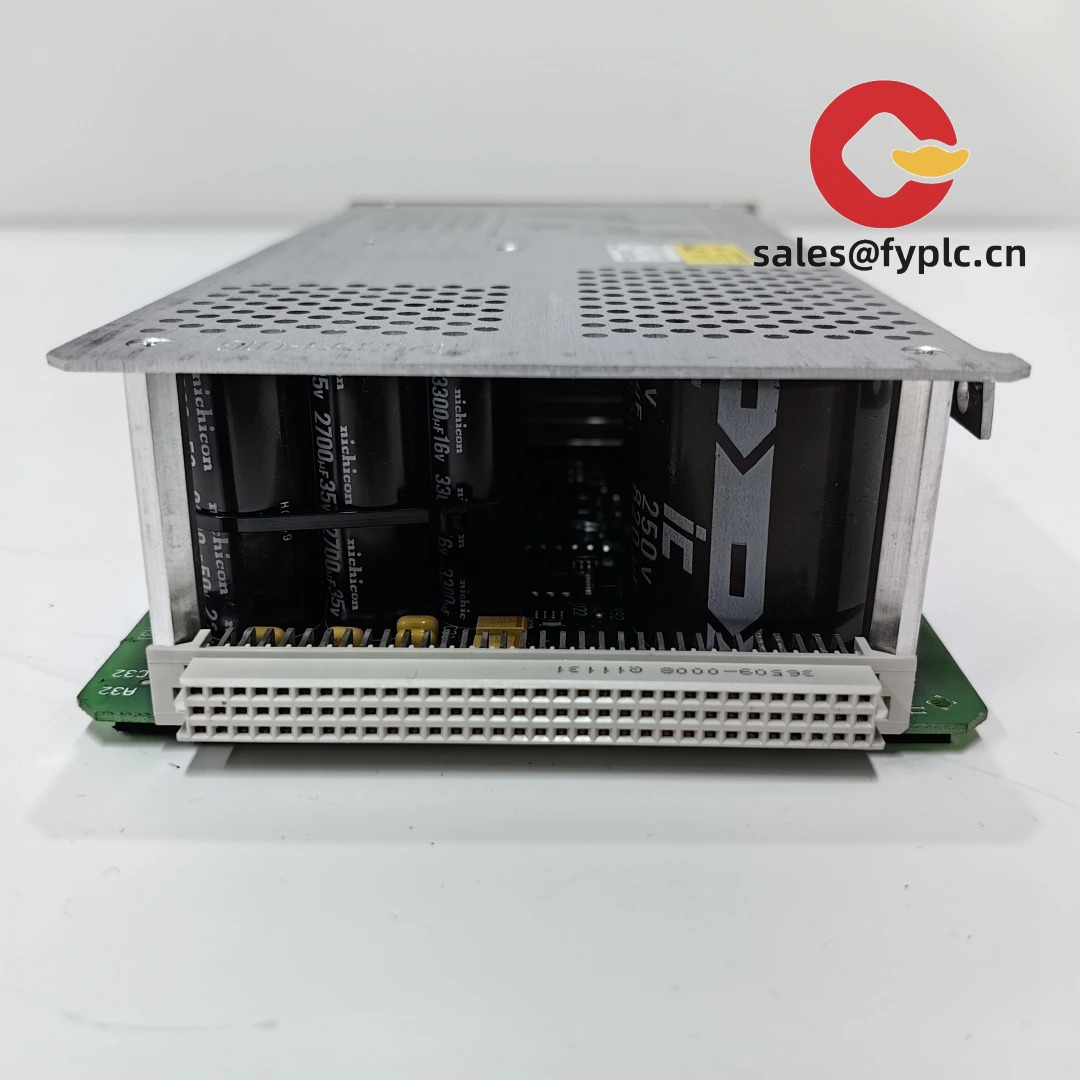

Bently Nevada 3500/15 114M5335-01 – Rack Monitor for Machinery Protection Systems

If you’re running rotating equipment in oil & gas, power generation, or large-scale industrial processing, the Bently Nevada 3500/15 monitor is typically a go-to for reliable shaft vibration and position monitoring. From my experience, this particular model—114M5335-01—shows up most often in turbine-driven systems where uptime matters and failure isn’t an option.

One thing I appreciate is how it integrates into the broader 3500 framework. It’s not just a standalone module; it’s part of a scalable protection ecosystem that lets plants standardize on one platform across multiple asset types. You might notice that in many cases, teams prefer it over third-party alternatives simply because of long-term support and spare parts availability.

Key Features

- Dual-channel monitoring: Handles two independent sensor inputs (typically from eddy current probes), ideal for radial shaft vibration or axial thrust position.

- Configurable alarm logic: Supports user-defined trip points, delay settings, and bypass options during startup or maintenance windows.

- Modbus RTU communication: Enables integration with DCS or SCADA via RS-485 interface—handy when you need remote diagnostics without full 4-20mA replication.

- Live monitoring with self-diagnostics: Continuously checks internal circuitry and sensor health, reducing false alarms and unplanned outages.

- Redundant power input: Accepts dual 24 VDC supplies, which seems to be critical in mission-critical environments where single-point failures aren’t acceptable.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Bently Nevada / 3500/15 (114M5335-01) |

| HS Code | 85371090 – Automatic controls for industrial process applications |

| Power Requirements | Dual 18–32 VDC, redundant operation supported |

| Dimensions & Weight | Standard 3500 rack module: ~125 mm H × 25 mm W × 200 mm D / ~0.4 kg |

| Operating Temperature | 0°C to 70°C (ambient) |

| Signal Input/Output Types | Two differential eddy-current probe inputs; 4–20 mA output per channel; relay outputs for alarms/trips |

| Communication Interfaces | RS-485 Modbus RTU (optional) |

| Installation Method | Snap-in module for Bently Nevada 3500 rack chassis (backplane powered and communicative) |

Application Fields

This module tends to appear in high-value rotating assets—especially steam turbines, compressors, and centrifugal pumps found in refineries, LNG terminals, and combined-cycle power plants. In many cases, it’s used as part of a larger machinery protection system (MPS) where precise shaft movement detection can prevent catastrophic bearing damage. One customer told me they replaced older 3300 monitors with these after experiencing noise interference issues—the digital filtering here seems to make a noticeable difference in signal stability.

Advantages & Value

Procurement teams usually favor this model due to its compatibility with existing 3500 racks and proven track record in harsh environments. While there are cheaper vibration monitors out there, the real cost advantage comes from reduced engineering time during integration and lower risk of misconfiguration. Firmware updates are backward-compatible more often than not, which helps extend lifecycle planning. Also, having direct access to technical documentation and configuration tools like System 1 software adds value—especially during troubleshooting.

Installation & Maintenance

You’ll want to install this in a standard 3500 rack housed within a control cabinet meeting IP54 or better. Ventilation should allow for heat dissipation—don’t stack other high-power modules directly adjacent. Wiring must follow shielded twisted-pair practices, especially for probe cabling, to avoid EMI issues. Grounding at a single point is recommended. For maintenance, periodic calibration every 12–18 months is typical, though some sites stretch it based on historical performance. Don’t skip firmware checks—newer versions sometimes include improved fault detection algorithms.

Quality & Certifications

The unit carries CE, UL, and CSA certifications, and complies with RoHS directives. It’s designed and tested under ISO 9001 quality processes. The manufacturer warranty covers defects in materials and workmanship for 365 days from shipment date. Repairs or replacements are handled through authorized service centers, but field-replaceable units minimize downtime.

Ordering note: In-stock units ship within one week. Delivery takes no longer than four weeks if backordered. Payment requires 50% upfront, balance before dispatch. We typically use FedEx, UPS, or DHL for express delivery depending on destination and urgency.

Reviews

There are no reviews yet.