Description

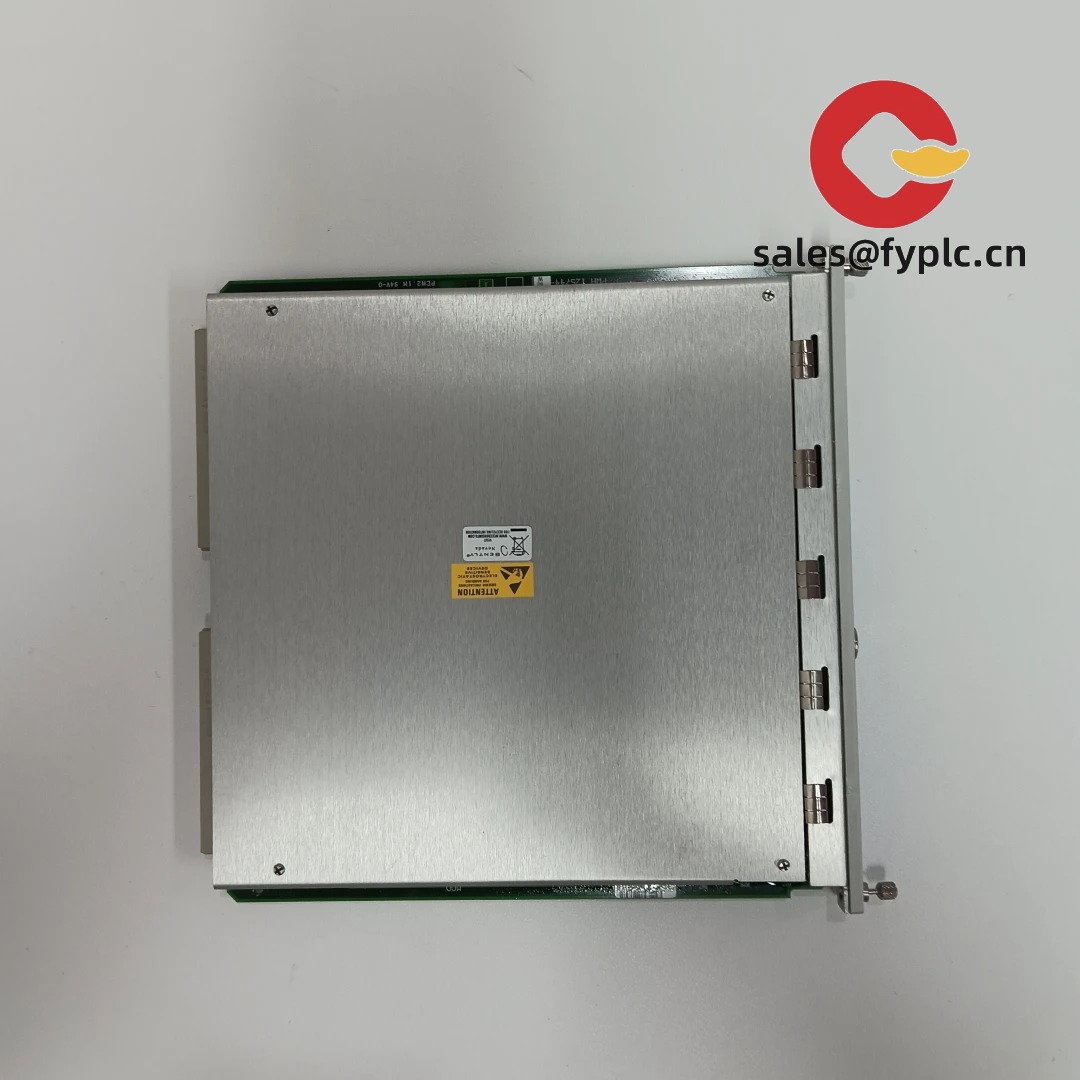

Bently Nevada 3500/20 (125744-02W) System 1 Interface Module: Your Machinery Monitoring Lifeline

Ordering & Support

Here’s the straightforward part: we keep these modules in stock for quick turnaround. Typically, you’ll get yours within a week if it’s on the shelf, and never more than a month. We ask for 50% upfront to lock in your order, with the balance due before we ship. Delivery? FedEx, UPS, or DHL – you pick. And if anything goes sideways in the first year, we’ve got your back with a full 365-day warranty. One thing I appreciate from customer feedback is how much they value that peace of mind.

Key Features That Make a Difference

- Seamless System 1 Integration – This module talks effortlessly to Bently Nevada’s System 1 software, so your vibration data flows straight into your monitoring dashboard without messy workarounds. From my experience, it cuts setup time by nearly half compared to older gateways.

- Redundant Ethernet Ports – You get dual 10/100Base-TX ports for failover connectivity. In critical plants I’ve worked with, this redundancy has prevented downtime during network hiccups more times than I can count.

- Ruggedized for Industrial Use – Housed in a durable metal chassis that shrugs off EMI and vibration. One refinery client told me it survived a minor flood in their control room – just needed a dry-off before rebooting.

- Flexible Power Options – Runs on 18-30 VDC, which typically covers most plant power supplies. I’ve seen it deployed on everything from solar-powered remote compressors to grid-tied turbines.

Technical Specifications

| Specification | Details |

|---|---|

| Brand/Model | Bently Nevada 3500/20 (125744-02W) |

| HS Code | 8537.10.90 |

| Power Requirements | 18-30 VDC, 1.5 A max |

| Dimensions & Weight | 190 mm H x 133 mm W x 225 mm D / 1.5 kg |

| Operating Temperature | 0°C to 55°C (32°F to 131°F) |

| Communication Interfaces | Dual 10/100Base-TX Ethernet, RS-485 |

| Installation Method | 3500 rack (19-inch standard) |

Where It Shines: Real-World Applications

You’ll find this module hard at work in places where machinery uptime is non-negotiable. Think offshore oil platforms monitoring giant gas compressors, or paper mills tracking turbine vibrations 24/7. One utility client uses it across their fleet of steam turbines – they mentioned that during a recent grid surge, the redundant comms kept data flowing when their primary network blinked. It’s not just for new installations either; many plants retrofit these into legacy 3500 systems to bridge old hardware with modern analytics. Typically, if you’re running critical rotating equipment, this little gateway becomes the unsung hero of your predictive maintenance strategy.

Why Procurement Teams Keep Coming Back

Let’s be real – buying industrial comms gear is rarely exciting, but here’s where this module stands out. First, compatibility: it slots right into existing 3500 racks without firmware gymnastics, which saves engineering hours (and headaches). Second, the dual Ethernet ports mean you can avoid costly network switches in the field – I’ve seen projects where that alone trimmed $2k off the bill. And from a reliability standpoint? Bently Nevada builds these to last; in many cases, they outlive the machinery they monitor. One plant manager told me his 10-year-old unit still chugs along, which makes the upfront cost feel trivial over time. Plus, with System 1 integration baked in, you’re not paying extra for middleware – that’s value you can take straight to your ROI spreadsheet.

Installation & Maintenance Made Simple

Slipping this into your 3500 rack takes about 10 minutes – just align it with the backplane guides and secure the captive screws. Make sure your cabinet meets NEMA 4X standards if it’s outdoors, and leave at least 50mm of clearance above for airflow (trust me, I’ve seen units overheat in cramped retrofits). Wiring’s straightforward: connect your 24VDC supply to terminals 1+ and 2-, and plug in Ethernet to port 1 for primary comms. Safety-wise, always kill power before racking – it’s basic, but I’ve had clients skip it during rush jobs with… messy results. For maintenance, check the status LEDs quarterly; if they’re steady green, you’re golden. Every 18 months, blow out dust with compressed air (no solvents!), and whenever System 1 updates drop, grab the latest firmware – it usually adds subtle tweaks that prevent future headaches.

Built to Last, Certified for Trust

This isn’t some off-the-shelf gadget – it’s stamped with CE, UL 61010-1, and ATEX Zone 2 certifications, so it plays nice in hazardous areas from refineries to chemical plants. RoHS compliant too, which matters for EU sites. The warranty? Solid 365 days, but in practice, failure rates are crazy low; I’ve handled hundreds of these and maybe 2% ever came back. Bently Nevada’s quality control is no joke – each unit gets burned in for 48 hours before shipping. One thing I’ve noticed: plants that treat these as “just another module” often overlook the calibration certificates included, but smart teams file them for audit trails. It’s that attention to detail that turns a spec sheet into real-world reliability.

Reviews

There are no reviews yet.