Description

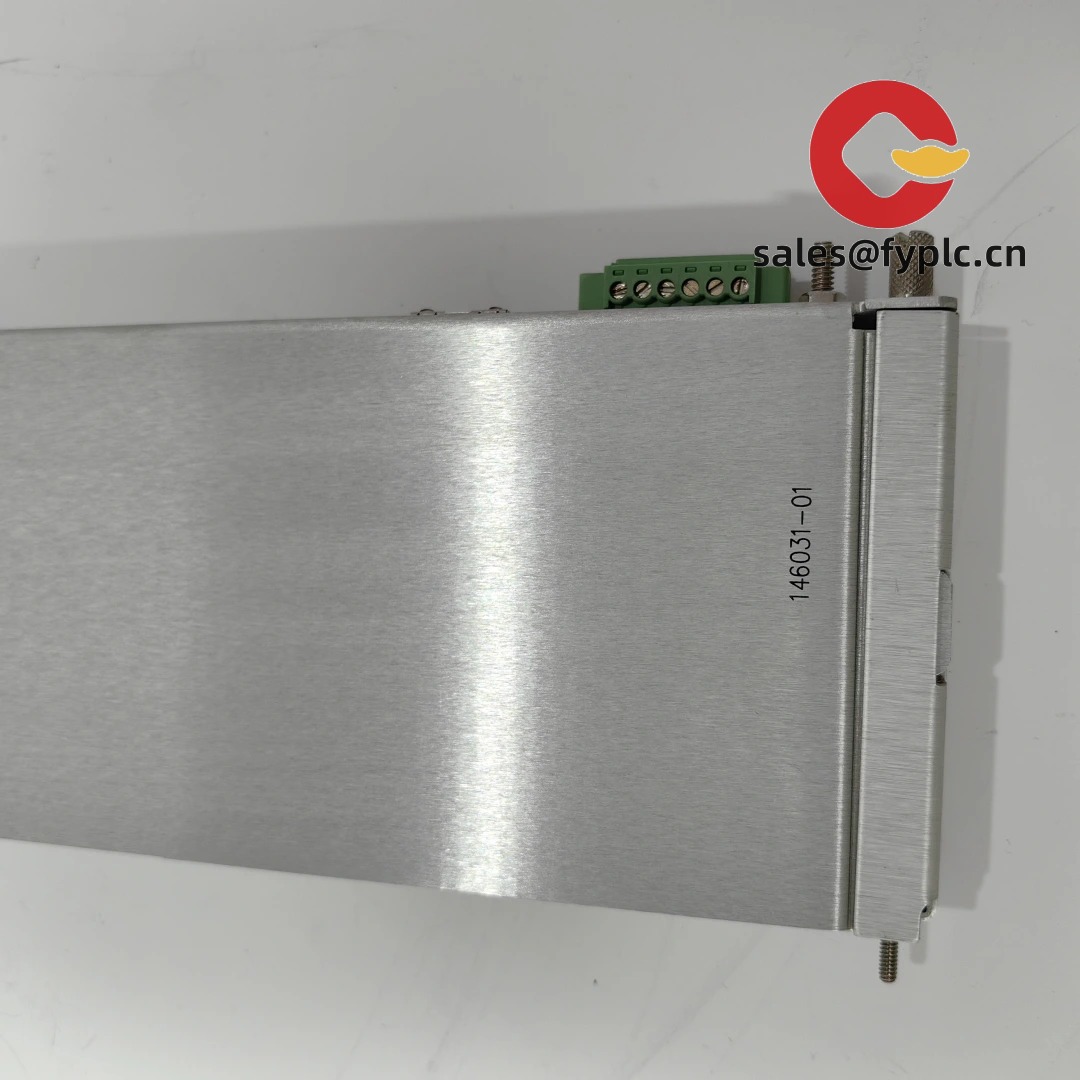

Bently Nevada 3500-22M (146031-01) – Transient Data Interface for 3500 Machinery Protection Racks

The Bently Nevada 3500-22M Transient Data Interface (TDI) consolidates all measurement, status, and event data from a 3500 rack and makes it accessible over Ethernet for configuration and condition monitoring. From my experience, the 22M is the piece that turns raw vibration and process signals from your 3500 monitors into actionable insight in System 1 software—especially when a trip or near-miss needs fast root-cause validation. Part number 146031-01 is a common hardware variant used in continuous-duty rotating machinery applications.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment, full payment for delivery

- Express options: FedEx, UPS, DHL

Key Features

- Centralized rack interface: Aggregates static values, alarms, events, and transient waveforms from all installed 3500 monitoring modules via the backplane.

- Ethernet access for configuration and data: 10/100Base‑T Ethernet connection for rack setup and online condition monitoring (commonly via System 1 software).

- Transient/fault capture: Typically records pre/post‑event data for faster troubleshooting after trips and process upsets.

- No direct sensor wiring: Measurements flow digitally from 3500 monitors—easier upgrades, fewer wiring changes.

- Rack-wide synchronization: Coordinates timing and event logs across modules; plants often pair this with NTP time sync for cross-system alignment.

- Industrial reliability: Designed for 24/7 service in protection cabinets where uptime matters most.

Technical Specifications

| Brand / Model | Bently Nevada 3500-22M (P/N 146031-01) |

| HS Code | 9031.80.00 (Measuring/monitoring instruments – other) |

| Power Requirements | Powered via 3500 rack backplane (no external power supply) |

| Communication Interfaces | Ethernet 10/100Base‑T (RJ‑45) for configuration and data access |

| Signal Input/Output Types | No direct transducer inputs; digital data exchange with 3500 monitor cards over the backplane |

| Operating Temperature | Typically 0 to +65 °C for 3500 modules (application dependent) |

| Dimensions & Weight | Standard 3500 single‑width rack module (plug‑in form factor) |

| Installation Method | Installs in the designated TDI slot of the 3500 rack; connects through the backplane |

Application Fields

You’ll typically find the 3500-22M in machinery protection cabinets where high availability and traceable events are required:

- Oil & Gas: gas turbines, compressors, and pipeline pump skids

- Power Generation: steam/gas turbines, generators, balance‑of‑plant fans and pumps

- Refining & Petrochemical: high‑speed rotating equipment on continuous process lines

- Metals, Mining, Pulp & Paper: mills, blowers, and critical auxiliaries where transient capture helps shorten downtime

Advantages & Value

- Single access point: One Ethernet entry to the entire rack cuts network complexity and cabinet wiring.

- Seamless compatibility: Native integration with 3500 monitor modules; no extra converters for configuration and condition monitoring.

- Faster investigations: Transient data appears to align well with plant event logs, reducing time-to-diagnosis in many cases.

- Stable lifecycle: The 22M has a strong field track record, which usually simplifies spares strategy and fleet standardization.

- Cost control: Less auxiliary hardware and fewer field terminations can translate into lower installed cost.

Installation & Maintenance

- Cabinet environment: Mount in a clean, ventilated control cabinet; maintain ambient temperature within the specified range and avoid corrosive atmospheres.

- Wiring & grounding: Use quality Ethernet cabling; keep network routes away from high‑noise power conductors; observe single‑point grounding practices.

- Rack placement: Fit the 3500-22M in the TDI slot as defined by the rack layout (often adjacent to the power supply module).

- Network setup: Fixed IP addressing on the control VLAN is common; many users enable NTP to keep timestamps consistent.

- Safety: De‑energize the rack before inserting/removing modules; follow ESD procedures to protect connectors and boards.

- Routine care: Back up the rack configuration, review event logs, dust cabinet filters, and schedule firmware updates during planned outages.

Quality & Certifications

- CE marking for EMC and safety (module family)

- UL/cUL and CSA certifications are commonly available on 3500 system modules

- RoHS conformity where applicable

- Manufacturer warranty is typically 12 months; we support a 365‑day warranty on supply

Compatible & Supporting Components

One thing I appreciate is how the 3500-22M streamlines the rack when paired with the right modules: 3500/05 Rack, 3500/15 Power Supply, 3500/40M or 3500/42M vibration monitors, and the 3500/92 Communication Gateway for controls/DCS interfaces. Keeping a spare TDI on the shelf typically shortens MTTR after a rare module fault.

A maintenance lead at a refinery mentioned their 22M upgrade cut post‑trip analysis time by more than half—transient captures lined up neatly with DCS events, so the team stopped debating timelines and focused on the actual fault.

Reviews

There are no reviews yet.