Description

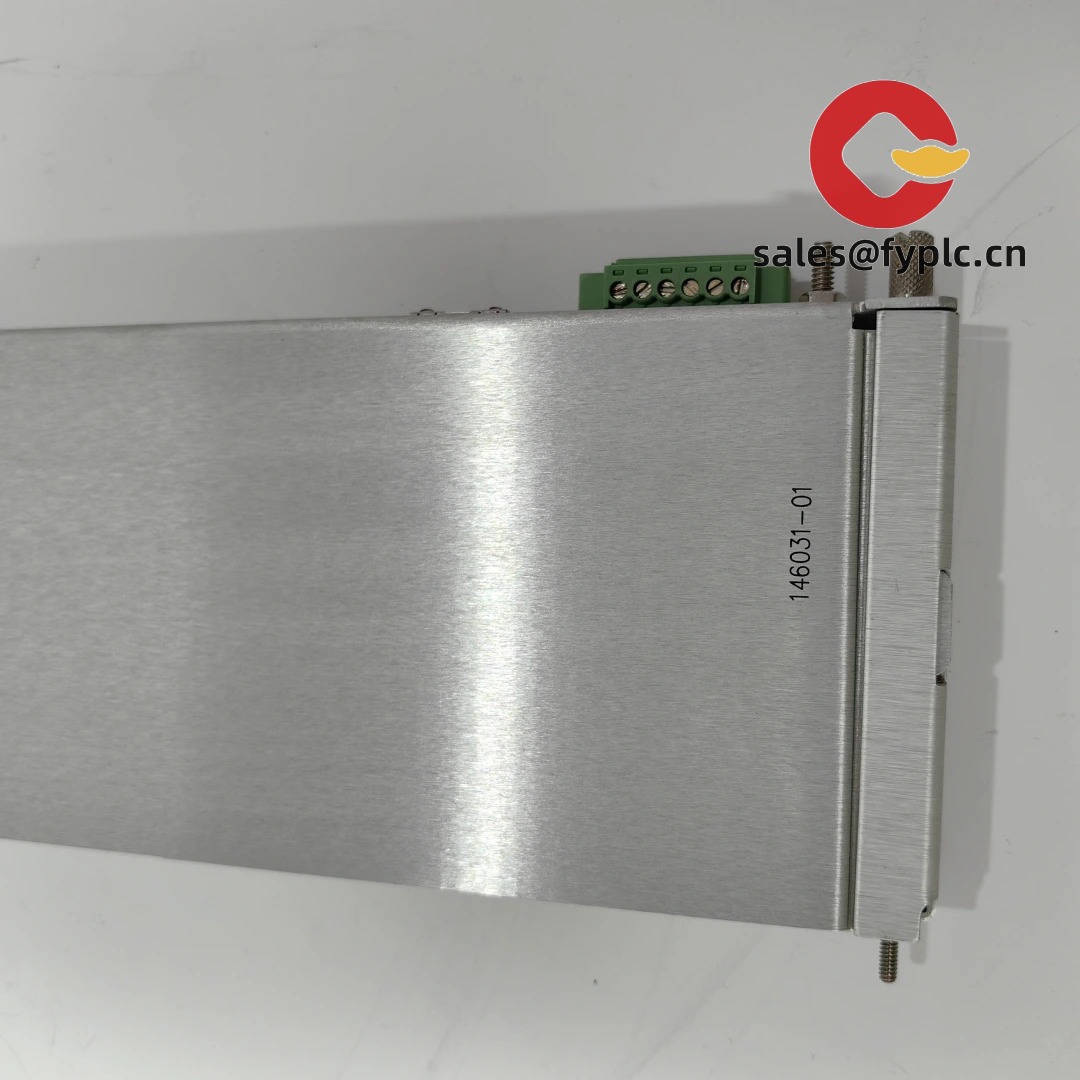

Bently Nevada 3500/22M Vibration Monitor (Model 146031-01) — High-Integrity Shaft Monitoring for Critical Rotating Equipment

Used across refineries, power plants, and large compressor stations for over two decades, the Bently Nevada 3500/22M is one of those modules you rarely hear about—until it’s missing. It’s not flashy, but it’s the quiet watchdog inside the 3500 rack that continuously validates proximity probe signals, calculates vibration severity (peak-to-peak, RMS, 0–100 kHz), and triggers shutdowns *before* a bent shaft or bearing failure takes out a $2M turbine. Model 146031-01 is the latest revision—backwards compatible with legacy 3500 systems, but with improved noise immunity and tighter channel synchronization.

Key Features

- Dual-channel monitoring with independent alarm logic: Each channel handles its own probe (typically radial X/Y or axial position + vibration), with fully configurable high/low alarms and danger trips—no shared thresholds forcing compromises between sensitivity and nuisance tripping.

- Real-time signal validation & health checking: Monitors probe gap voltage, bias current, and cable integrity in real time; flags “probe open”, “short”, or “drift” conditions before they corrupt trend data—something many users only appreciate after a false trip during startup.

- Integrated relay outputs (4 total): Two form-C relays per channel—typically wired for Alarm 1, Alarm 2, Danger, and OK status—so you’re not juggling external relay modules just to meet API 670 requirements.

- Hot-swappable & rack-aware: Pulls configuration directly from the 3500 rack controller (e.g., 3500/15 or 3500/25); no manual dip-switch setup. From my experience, this cuts commissioning time by ~40% compared to older 1772-style monitors.

- Enhanced EMI resilience: The -01 revision includes revised filtering on the input stage—particularly helpful in facilities where VFDs or welding operations used to cause intermittent spikes on older 146031-00 units.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Bently Nevada / 3500/22M (146031-01) |

| HS Code | 8531.80.90 (Monitoring and control instruments for industrial processes) |

| Power Requirements | +24 VDC nominal (rack-supplied); operates from 20–30 VDC; typical draw: 180 mA |

| Dimensions & Weight | 173 mm H × 42 mm W × 227 mm D (6.8″ × 1.7″ × 8.9″); ~520 g |

| Operating Temperature | 0 °C to +60 °C (derated above 50 °C; condensation-free environment required) |

| Signal Input | Two independent 10–50 mV/mm proximity probe inputs (−10 to −26 VDC bias); supports standard 3-wire eddy-current probes (e.g., 3300 XL, 3309xx) |

| Signal Output | 4 x Form-C relays (2A @ 30 VDC resistive); 2 x 4–20 mA process outputs (channel-selectable) |

| Communication Interface | Embedded in 3500 rack architecture; communicates via backplane to 3500/15 or 3500/25 controller; no standalone Ethernet or serial port |

| Installation Method | DIN-rail mounted inside Bently Nevada 3500 rack (standard 19″ cabinet); requires rack controller and power supply module |

Application Fields

This isn’t a general-purpose monitor—it’s built for places where vibration misreads cost downtime, safety incidents, or regulatory penalties. You’ll find it on steam turbines in combined-cycle plants (monitoring thrust position and differential expansion), on centrifugal compressors in petrochemical trains (where phase analysis helps distinguish imbalance from misalignment), and increasingly in wind turbine gearboxes—though that usually requires supplemental firmware (v4.12+) and careful probe placement. One customer in Alberta told us their 3500/22M caught a developing bearing defect 72 hours before oil debris spiked—giving them time to schedule a planned outage instead of an emergency shutdown.

Advantages & Value

If you’re evaluating replacements or spares, here’s what typically matters most: First, interchangeability. The 146031-01 drops into any existing 3500 rack without reconfiguration—unlike some third-party clones that require jumper changes or firmware hacks. Second, support continuity: Baker Hughes still issues security patches and firmware updates for this model (latest is v4.15, released Q2 2024), and spare parts like front-panel membranes remain available through authorized channels. Third, total cost of ownership: While it’s pricier than a generic PLC analog module, the integrated diagnostics, API 670 compliance out-of-the-box, and reduced engineering time for alarm logic validation often justify the premium—especially when your reliability team tracks MTTR in minutes, not hours.

Installation & Maintenance

Mount only in a grounded, NEMA 12 or IP54-rated cabinet with ≥150 mm clearance above/below the module for convection cooling. Avoid locations near large transformers or variable-frequency drives unless shielded conduit and ferrites are used on all probe cables. Wiring must follow Bently Nevada’s 3500 System Installation Guide—especially grounding: probe shields terminate at the module end only (not at both ends), and the rack chassis ground must be ≤5 Ω to earth. For maintenance: verify relay operation quarterly using the front-panel test button; clean dust filters every 6 months (compressed air only—no solvents); and check calibration drift annually with a certified calibrator (±0.5% full scale is typical after 2 years). Firmware updates should only be performed during scheduled maintenance windows—and always backed up first.

Quality & Certifications

Certified to CE (2014/30/EU EMC Directive, 2014/35/EU LVD), UL 61010-1 (3rd Ed.), ATEX II 2G Ex ib IIC T4 Gb (for use in Zone 1 hazardous areas when installed per manual), and RoHS 3 compliant. ISO 9001:2015 quality system certified at manufacturing site. Comes with a full 365-day warranty covering parts and labor—no pro-rata clauses, no “exclusions for improper installation” fine print. If it fails under normal operating conditions within that year, we replace it outright.

Our Order Placement Process & Guarantees:

• Warranty: Full 365-day coverage—no questions asked if failure occurs under spec.

• Delivery: In-stock units ship within 1 week; non-stock lead time capped at 30 days.

• Payment: 50% advance, balance due before dispatch.

• Shipping: FedEx, UPS, or DHL express—fully insured, with real-time tracking.

• Note: We pre-test each 3500/22M before shipping—including relay cycling, input sweep, and alarm threshold verification—so what arrives is ready for rack insertion.

Reviews

There are no reviews yet.