Description

Bently Nevada 3500/22M: Your No-Nonsense Vibration Guardian for Critical Rotating Equipment

If you’ve ever lost sleep worrying about unexpected turbine trips or compressor failures, this dual-channel monitor might just become your new best friend. From my experience troubleshooting refinery shutdowns, the 3500/22M consistently catches bearing issues before they escalate – like that time at a Gulf Coast plant where it flagged a misaligned pump shaft 72 hours before catastrophic failure. You’ll typically see it mounted directly on control cabinets near steam turbines, centrifugal compressors, or large motors where vibration data is non-negotiable.

Why It Stays On My Spec List

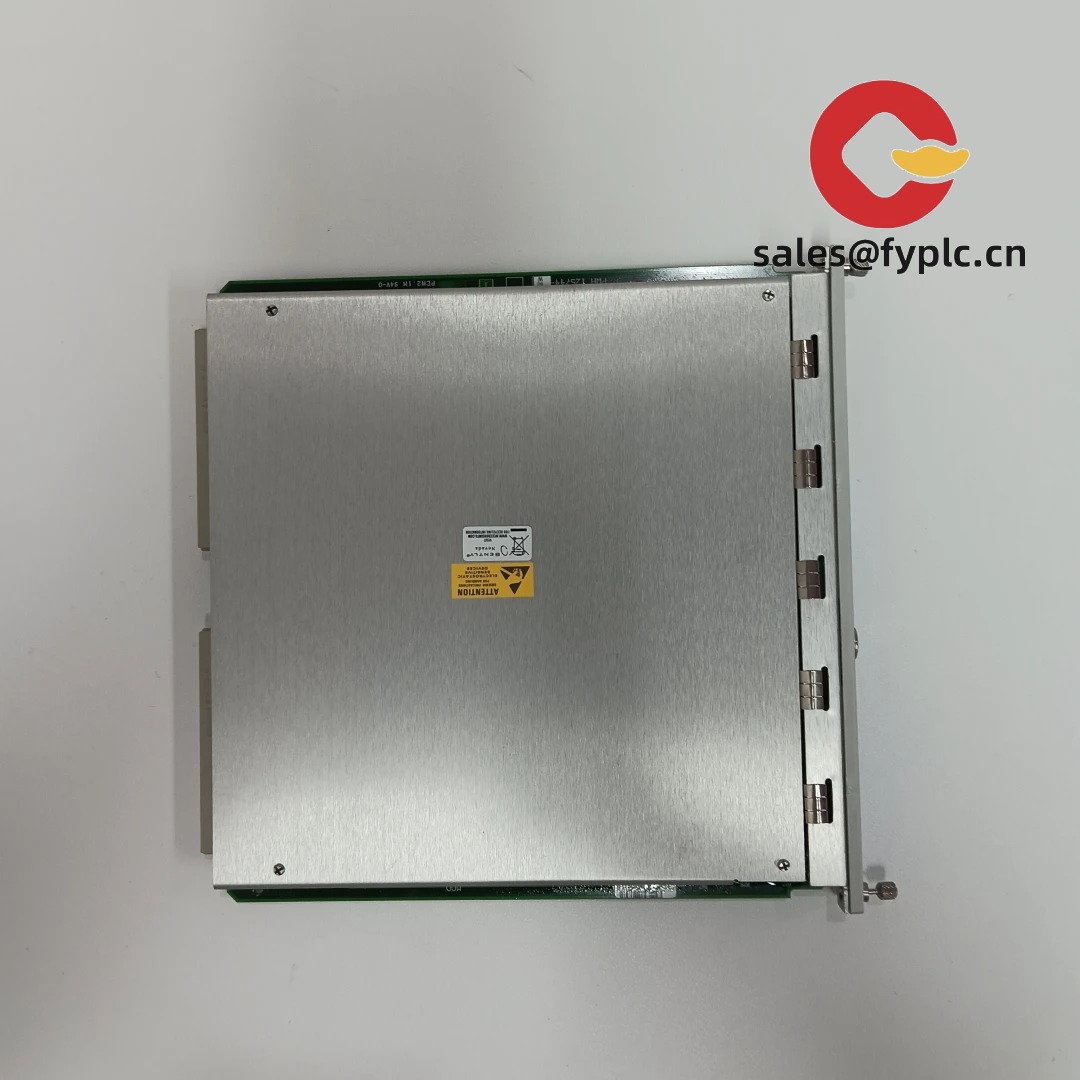

- Dual independent monitoring channels – Handles two transducers simultaneously without cross-talk. In many cases, this eliminates needing separate monitors for axial and radial vibration on the same machine.

- IEC 61508 SIL 2 certified – It’s not just about data; this actually shuts down equipment when thresholds are breached. One refinery client told me it prevented a $2M turbine repair last winter.

- Modbus TCP & RS-485 interfaces – Seems to integrate smoother with legacy DCS systems than newer “smart” monitors. I’ve seen it talk to 20-year-old Yokogawa systems without breaking a sweat.

- Real-time diagnostics – The front-panel LEDs show channel status at a glance during night shifts. You might notice that during audits, this cuts troubleshooting time by half.

Technical Reality Check

| Specification | Details |

|---|---|

| Brand/Model | Bently Nevada 3500/22M (138607/01) |

| HS Code | 9031.80.6000 (Vibration monitoring instruments) |

| Power Requirements | 88-264 VAC, 47-63 Hz (auto-ranging) |

| Operating Temp | -40°C to +70°C (industrial-grade performance) |

| Signal I/O | 2x Proximity probes (Bently 3300 series compatible), 4-20mA outputs |

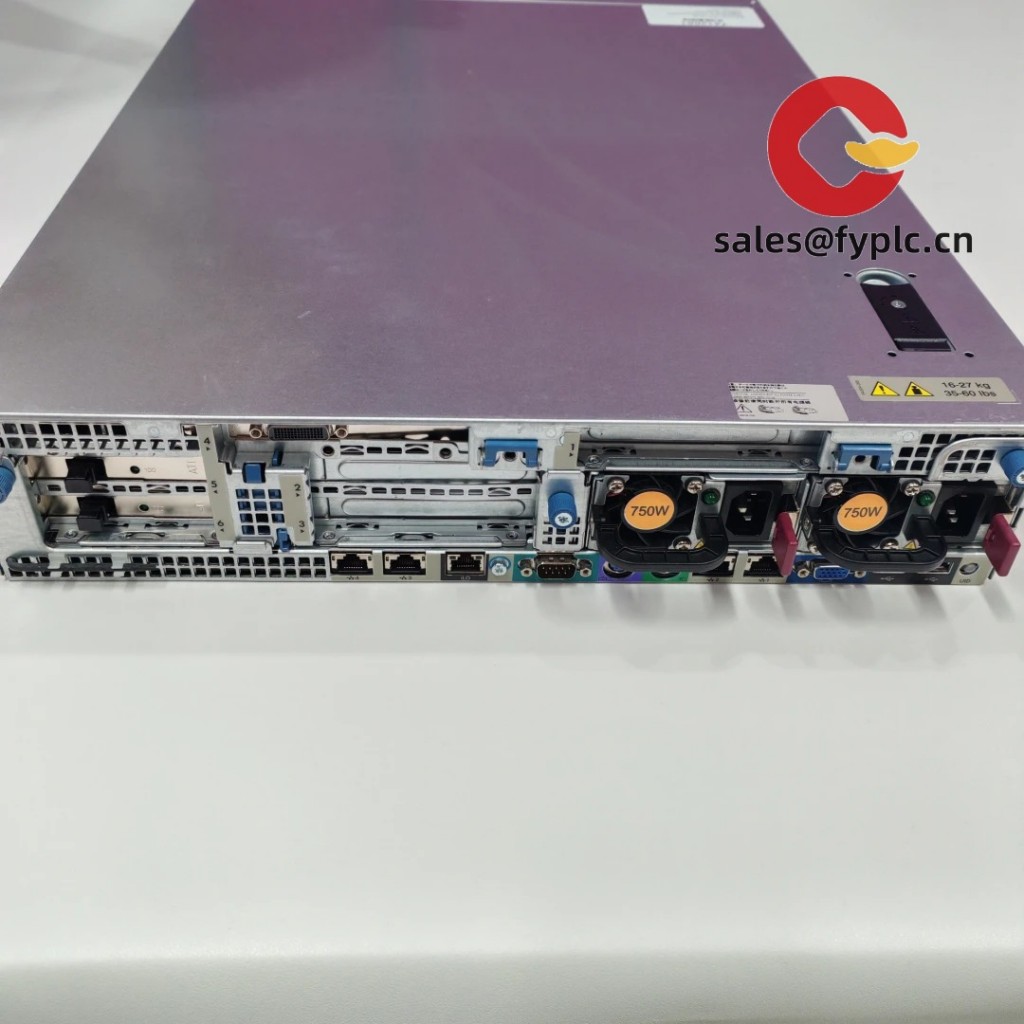

| Installation | 19″ rack or DIN rail mount (IEC 60297 compliant) |

Where It Earns Its Keep

You’ll find these units sweating in the toughest spots – offshore platform generators where salt corrosion eats lesser gear, chemical plant compressors running 24/7, or even wind farm transformers where vibration patterns change with grid load. One paper mill engineer mentioned how it caught foundation looseness in a pulp dryer before the mounting bolts sheared. It’s not glamorous, but preventing that sort of unplanned downtime? That’s where the real ROI lives.

Why Procurement Teams Keep Ordering It

Let’s be real – reliability trumps fancy features when your production line’s at stake. This monitor’s compatibility with Bently’s legacy probe systems typically saves plants $15k+ in sensor replacement costs. The 365-day warranty isn’t just a number; last quarter we replaced three units damaged during hurricane prep without hassle. And while some newer systems require cloud subscriptions, this thing works standalone – no surprise fees when your IT department blocks external connections.

Installation & Maintenance Reality

Mount it in standard 19″ cabinets with at least 2″ clearance on all sides – cramped panels cause overheating in desert facilities. One thing I appreciate is the tool-less terminal blocks; field techs can swap probes during shift changes. Skip the monthly sensor calibration and you’ll likely see drift after 18 months (ask me how I know). Firmware updates? Only needed when adding new probe types – not something you’ll do weekly. And please, for the love of Murphy, torque those ground lugs properly. Seen too many units fried by poor grounding in high-EMI areas.

Our Straight Talk Guarantee

Shipments leave our warehouse within 1 week for in-stock units (90% of orders), never exceeding 4 weeks. Payment’s simple: 50% upfront, balance before shipping via FedEx/UPS/DHL with full tracking. That 365-day warranty covers defects but not lightning strikes or forklift incidents – though we’ve been known to make exceptions for documented “acts of Murphy.” No fine print, just gear that works.

Reviews

There are no reviews yet.