Description

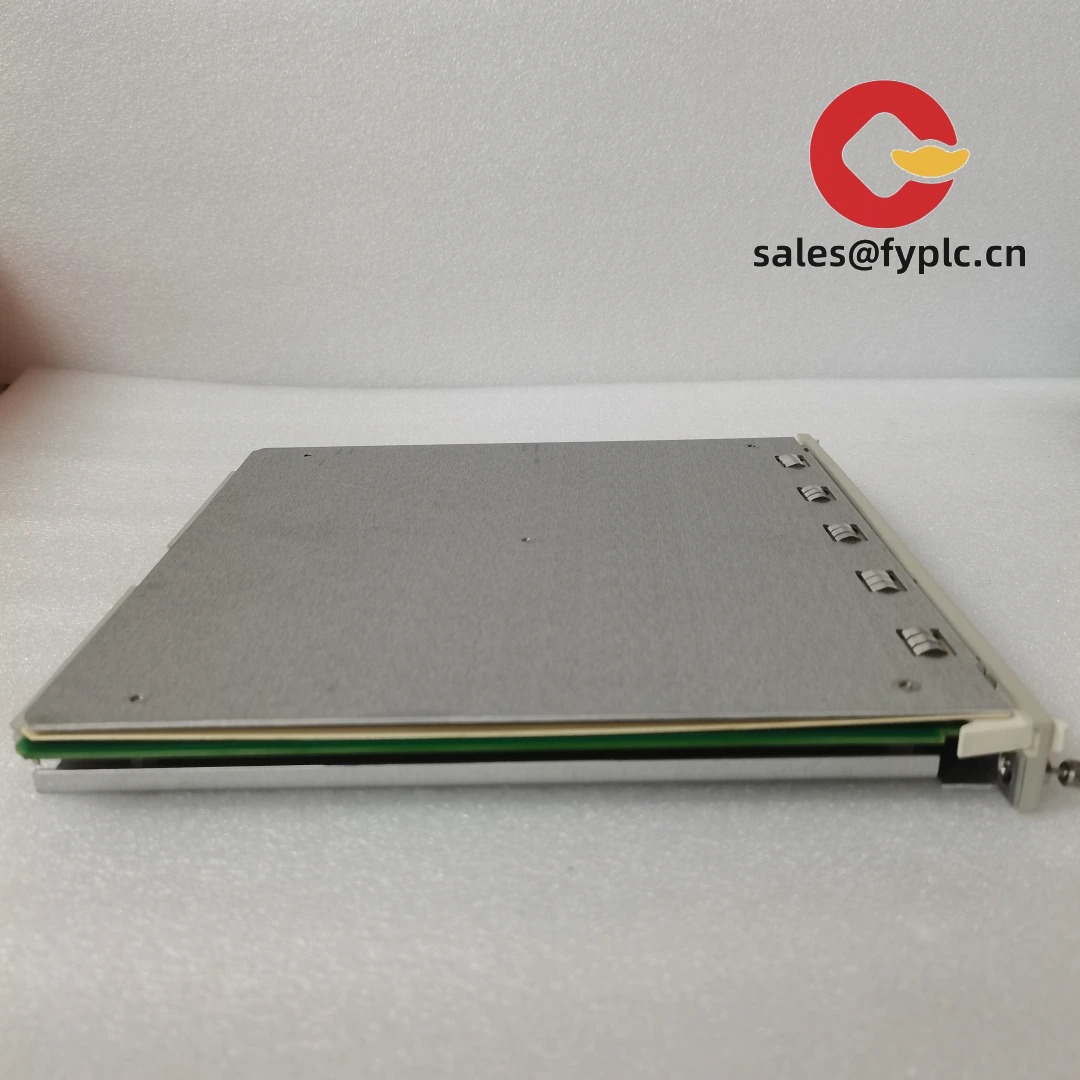

Bently Nevada 3500/33 149986-01 — Rack Monitor for Turbomachinery Protection

If you’re managing critical rotating equipment in oil & gas, power generation, or large-scale manufacturing, the Bently Nevada 3500/33 rack monitor isn’t just another module—it’s the central nervous system of your machinery protection setup. Model 149986-01 is a specific revision of the 3500/33 processor used in the 3500 monitoring system, typically handling communication, logic execution, and coordination between input modules and host systems.

Key Features

- Dual-Processor Architecture – Provides redundancy and continuous operation during faults; one processor typically handles monitoring while the other manages communications.

- Modbus RTU and Ethernet Support – You might notice that this model bridges older control systems with modern networks, making integration into legacy plants smoother.

- Event Logging and Alarm Management – Stores up to 200 event records, which from my experience has helped plant engineers diagnose trip events without needing external SCADA logs.

- Hot-Swappable Design – One thing I appreciate is that it can be replaced or serviced without shutting down the rack—critical in continuous-process environments.

- Configurable via System 1 Software – Works seamlessly with Bently’s asset management platform, allowing remote configuration and diagnostics in most cases.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Bently Nevada / 3500/33 (149986-01) |

| HS Code | 85371090 – Programmable controllers, other |

| Power Requirements | +24 VDC (redundant inputs typical) |

| Dimensions (H×W×D) | Approx. 140 × 35 × 180 mm (fits standard 3500 rack chassis) |

| Weight | ~0.5 kg |

| Operating Temperature | 0°C to 70°C (with derating above 55°C) |

| Signal I/O Types | Digital inputs/outputs for relay status, alarm signals |

| Communication Interfaces | RS-485 (Modbus RTU), Ethernet (Modbus TCP/IP optional via card) |

| Installation Method | DIN-rail mounted in 3500 Series rack chassis (e.g., 3500-20M) |

Application Fields

This module shows up most often in refineries where compressors need real-time shaft vibration monitoring, or in combined-cycle power plants protecting steam turbines. It’s also found in LNG facilities monitoring feed-gas compressors—places where unplanned downtime costs tens of thousands per hour. The 3500/33 acts as the decision-maker: receiving data from proximity probes, accelerometers, and speed sensors, then triggering alarms or trips based on pre-set logic.

A customer in Texas recently mentioned they’d swapped out an older 3500/22 with this 149986-01 revision to gain better network visibility—turns out the Ethernet option saved them from installing a separate gateway.

Advantages & Value

From a procurement standpoint, sticking with the 3500 platform means spare part commonality across sites. Even though newer systems exist, many plants still rely on this architecture because replacement would mean re-engineering entire protection schemes.

In many cases, upgrading firmware rather than hardware gives you improved diagnostics and security without changing cabinet layouts. That said, compatibility matters—this version requires matching firmware with adjacent modules, so cross-checking part numbers before ordering is wise.

Installation & Maintenance

Install only in a clean, well-ventilated control cabinet meeting NEMA 12 standards. Avoid shared power supplies with high-noise equipment—dedicated 24V lines are best. Wiring should use shielded twisted pair for communication lines, grounded at one end.

Routine checks every six months typically include verifying LED status patterns, checking for error logs, and ensuring the backup battery (if present) hasn’t degraded. Firmware updates should be done during planned outages—always back up configuration first.

Quality & Certifications

Certified to CE, UL 60950-1, and compliant with RoHS directives. Designed and tested under ISO 9001 quality processes. The unit comes with a 365-day warranty, covering defects in materials and workmanship—no questions asked if failure occurs under normal operating conditions.

Ordering & Delivery: 50% advance payment required; balance due before shipment. In-stock units ship within one week; maximum lead time is four weeks. We use FedEx, UPS, or DHL for global deliveries—tracking provided automatically.

Reviews

There are no reviews yet.