Description

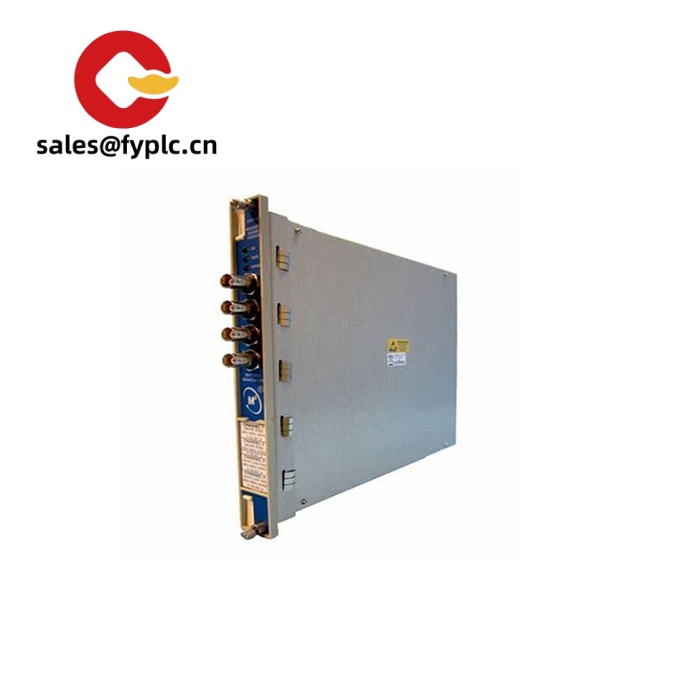

Bently Nevada 3500/42-09-01: 4‑Channel Proximitor/Seismic Monitor for Critical Rotating Equipment Protection

If you’re trying to catch bearing wear early or keep a compressor from nuisance trips, this variant tends to be the safe bet. From my experience on refinery trains, the 3500/42-09-01 gives you four flexible channels that can take proximitor (eddy‑current) and seismic inputs on the same card—handy when a machine set mixes shaft vibration, thrust position, and casing vibration. It drops into the 3500 rack, plays nicely with the TDI, and just behaves, even when the process gets messy.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment for delivery

- Express delivery options: FedEx, UPS, DHL

Key Features

- Four independent channels – Cover two radial bearings, thrust position, and one casing seismic point on a single module; typically cuts card count per train.

- Proximitor + seismic support – Accepts eddy‑current proximity probes, IEPE accelerometers, and velocity pickups. One thing I appreciate is not having to swap hardware when the sensor mix changes.

- API 670‑style alarming – Alert/Danger setpoints with latching and configurable delays; you might notice fewer nuisance trips at startup and coast‑down.

- Buffered BNC outputs – Analysts can pull clean raw signals for balancing, bump tests, and coast‑down plots without disturbing field wiring.

- Keyphasor referencing – Tracks phase and speed using rack Keyphasor inputs for orbit/1× tracking and synchronous measurements.

- Native 3500 integration – Values and events flow over the backplane to the 3500/22M (TDI) for System 1 viewing and DCS gateways.

Technical Specifications

| Item | Details |

|---|---|

| Brand/Model | Bently Nevada 3500/42-09-01 |

| HS Code | 9031.80.90 (Machinery vibration/position monitoring instruments) |

| Channels / Inputs | 4 channels; eddy‑current proximity probes (shaft vibration, thrust), IEPE accelerometers, or velocity pickups; front buffered outputs |

| Measurement & Alarms | RMS/peak with configurable band/filters; Alert & Danger setpoints with latching/time delay; OK status per channel |

| Power Requirements | Powered from 3500 rack backplane (typical consumption low; no external PSU) |

| Operating Temperature | Typically 0°C to +65°C, non‑condensing |

| Communication Interfaces | Via 3500 backplane to 3500/22M (TDI) for System 1 / historian / DCS gateways |

| Installation Method | 1‑slot 3500 rack module; rear terminal wiring; front BNCs for buffered signals |

Application Fields

Suited for steam/gas turbines, centrifugal compressors, big process pumps, blower trains, gearboxes, and paper machine rolls. A common setup I see: two proximitor channels on radial bearings, one thrust position, and one seismic on the gearbox casing—simple and effective for catching problems early without overbuilding the rack.

Advantages & Value

- Reliability – Proven 3500 architecture; fewer nuisance alarms when delays and bands are tuned to the machine’s speed profile.

- Compatibility – Works seamlessly with 3500/22M TDI, relay modules, and 4‑20 mA output modules (3500/93).

- Cost control – Four points per card means fewer modules per train; buffered outputs cut analyst time during outages.

- Supportability – Crews know the 3500/42 workflow; configuration and swaps can be done quickly during tight shutdown windows.

Installation & Maintenance

Keep probe and seismic cables away from VFD feeders (aim for 300 mm separation); ground shields at one end to avoid loops. After thermal soak, re‑verify proximitor gaps—thermal growth shifts them more than we’d like. One thing I always do is map channels to the Keyphasor once and label the cabinet; it saves hours during night‑shift callouts.

- Cabinet: 19″ rack enclosure, IP54+ with front/rear ventilation space

- Wiring: Twisted, shielded pairs for proximitor and seismic runs; clean, single‑point grounding

- Routine care: Quarterly buffered‑BNC spot checks; semi‑annual setpoint review; firmware updates via TDI during planned outages

- Safety: Lockout/tagout before sensor work; keep harnessing dressed and strain‑relieved to avoid intermittent faults

Quality & Certifications

CE and UL compliant; manufactured under ISO 9001. Designed to support API 670 practices when configured correctly in the 3500 rack. Warranty is 365 days—most issues we see in the field turn out to be wiring or sensor related, but you’re covered under normal operation either way.

Reviews

There are no reviews yet.