Description

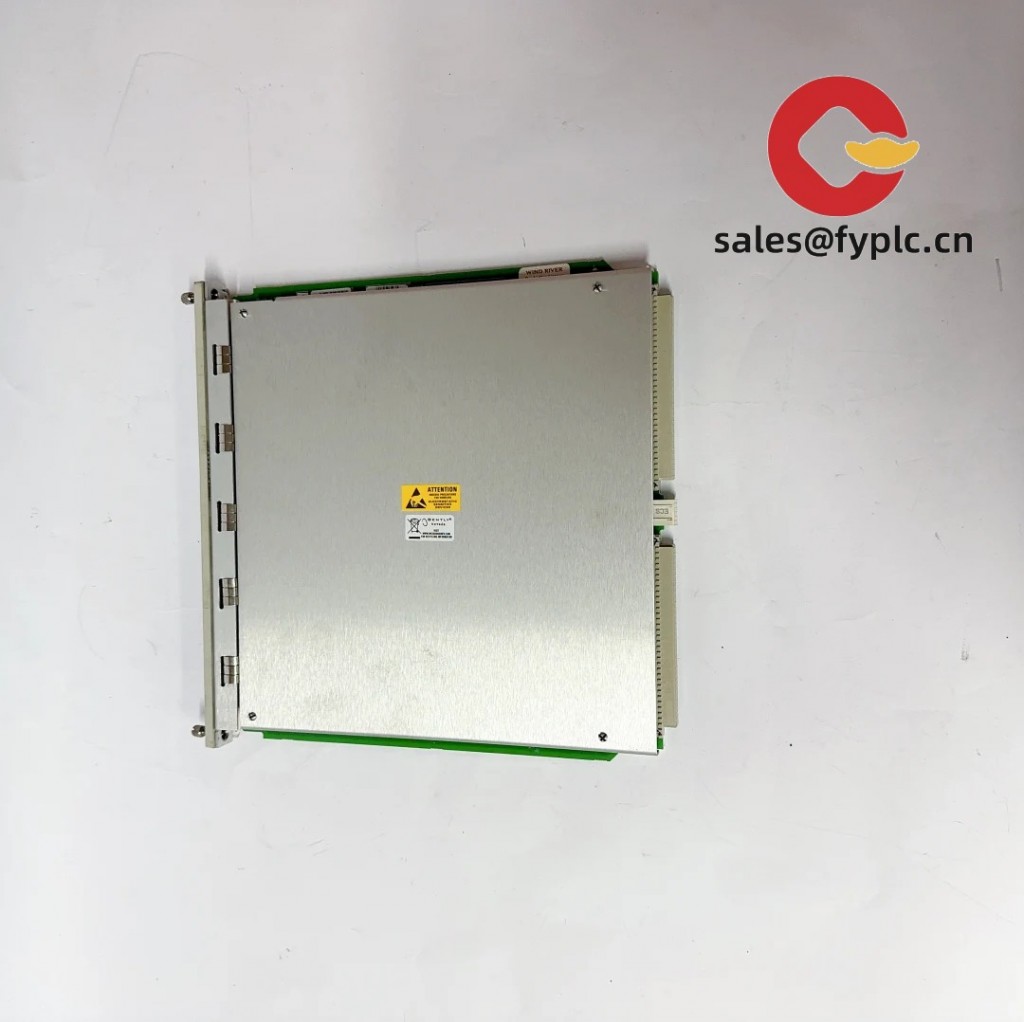

Bently Nevada 3500/42M 128229-01 — High-Performance Dual-Channel Vibration Monitor for Critical Machinery Protection

If you’re responsible for protecting turbines, compressors, or large rotating equipment, the Bently Nevada 3500/42M (128229-01) is one of those modules that tends to show up in high-reliability environments—especially where uptime matters more than cost cutting. From my experience, it’s not just about detecting vibration; it’s about doing so with enough intelligence and redundancy to prevent false trips while still catching real issues early.

Key Features

- Dual-channel monitoring – Handles two independent vibration input sources, typically used for radial shaft vibration via proximity probes. This allows full shaft orbit analysis when paired with appropriate software.

- 4–20 mA output per channel – Seems to be standard across most installations, making integration with PLCs or DCS systems straightforward without needing additional signal conditioning.

- Relay-based alarm outputs – Four configurable relays (danger, warning, pre-alarm, etc.) that typically latch on trip but can be set for auto-reset depending on your safety philosophy.

- Modbus RTU over RS-485 – One thing I appreciate is that even though it’s not Ethernet-ready, the serial communication holds up well in electrically noisy areas, which you often see near motor control centers.

- Front-panel display and keypad – Lets technicians view live values, calibrate sensors, or acknowledge alarms locally—useful during commissioning or troubleshooting without pulling out a laptop.

- Built-in self-diagnostics – Monitors sensor health, gap voltage, and module integrity. You might notice fault indicators lighting up before actual process disruption occurs.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Bently Nevada / 3500/42M (128229-01) |

| HS Code | 8537.10.90 (Control panels incorporating programmable logic controllers or microprocessors) |

| Power Requirements | +24 VDC nominal (range: +18 to +30 VDC), dual redundant power inputs typical |

| Dimensions & Weight | Approx. 130 mm × 115 mm × 220 mm (W×H×D); ~1.8 kg |

| Operating Temperature | 0°C to 70°C (ambient) |

| Signal Input Type | Two channels of eddy current proximity probe input (e.g., 5 V/mm or 200 mV/mil) |

| Output Signals | Two isolated 4–20 mA outputs, four SPDT relay outputs (5 A @ 250 VAC) |

| Communication Interface | RS-485 Modbus RTU (used for remote monitoring and configuration via host system) |

| Installation Method | DIN-rail mounted within Bently Nevada 3500 rack chassis (Model 3500/15 or equivalent) |

Application Fields

This module pops up frequently in oil & gas, petrochemical, and power generation plants—particularly around centrifugal compressors, steam turbines, and large pumps. In many cases, it’s part of an overall machinery protection system (MPS) where avoiding catastrophic failure outweighs initial hardware costs. It’s also common in facilities undergoing digital transformation but still relying on proven analog architectures; the 3500 platform bridges that gap fairly well.

Advantages & Value

While newer systems offer full Ethernet/IP connectivity and predictive analytics, this model remains popular due to its reliability under harsh conditions. Procurement teams tend to favor it because spare parts are widely available, and maintenance staff already know how to troubleshoot it—no retraining needed. Compatibility with existing 3500 racks means upgrading individual modules doesn’t require ripping out entire cabinets. And since it supports hot-swapping (when used with redundant power), unplanned downtime stays low.

Another subtle benefit: the relay logic is deterministic. Unlike some software-configured safety systems, what you configure is exactly what executes—no firmware bugs interfering with trip decisions. That predictability matters in SIL-rated applications, even if it’s not formally certified as such.

Installation & Maintenance

Install only in clean, dry enclosures meeting NEMA 12 or IP54 standards. Make sure the DIN rail is securely fastened and the backplane connections are fully seated—loose connectors are one of the top causes of intermittent faults. Provide adequate ventilation; don’t stack heat-generating modules directly above it. Use shielded twisted-pair wiring for all analog signals, grounding shields at one end only to avoid ground loops.

For maintenance, perform quarterly visual checks for LED status anomalies. Calibrate annually using traceable standards, especially if operating near environmental extremes. Firmware updates aren’t frequent, but when available, apply them during planned outages using the TSI software tool. Keep spare fuses and relays on hand—they’re inexpensive but can halt operations if missing during a fault event.

Quality & Certifications

The 3500/42M meets CE, UL, and CSA standards for industrial control equipment. It complies with RoHS directives and is designed to operate reliably in accordance with ISO 10816 vibration severity guidelines. Electromagnetic compatibility follows EN 61326-2-3 for industrial environments.

Our warranty covers defects in materials and workmanship for 365 days from shipment date. No questions asked—if it fails under normal use, we replace it. Units are tested prior to shipping, including power-up verification and basic signal simulation.

Ordering Notes: Delivery takes 1 week for in-stock units, or no more than one month if backordered. We accept FedEx, UPS, or DHL for express delivery. Payment requires 50% advance, with full balance due before shipment. International shipments include commercial invoice and packing list.

Reviews

There are no reviews yet.