Description

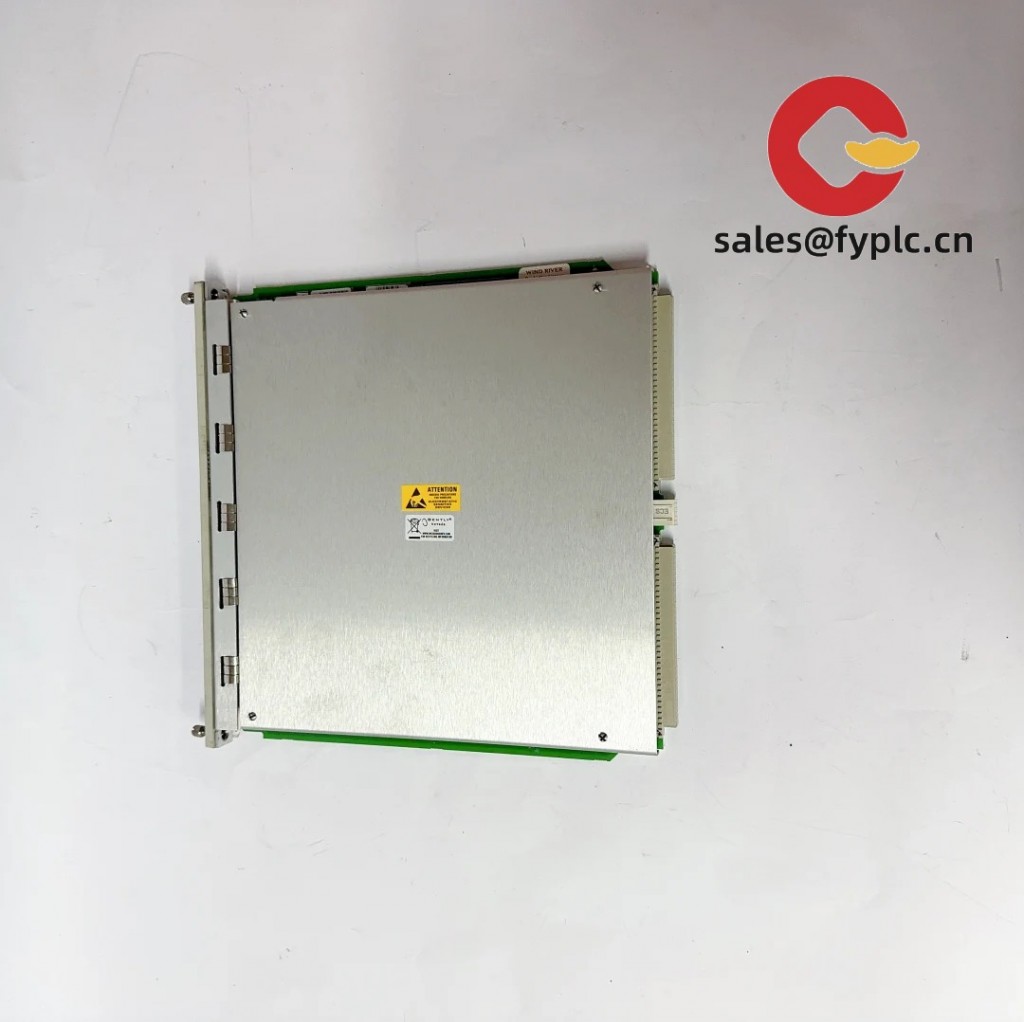

Bently Nevada 3500/42M (140482-01) — Dual-Channel Monitor for Radial & Thrust Vibration Protection

One thing I appreciate is how consistently this module shows up in retrofits—especially where legacy 3500 racks are still running critical compressors or steam turbines. It’s not flashy, but it does one job extremely well: monitoring two independent vibration channels (typically radial + axial) with true RMS detection, alarm latching, and seamless integration into the broader 3500 system. A plant engineer in Houston told me last month they swapped out a failing 3500/40 with this unit during a weekend outage—and had full protection back online before Monday shift change.

Key Features

- Dual-channel vibration monitoring: Handles both radial (bearing housing or shaft) and thrust position/vibration inputs simultaneously—no need for separate modules in many mid-tier applications.

- True RMS detection with peak hold: Better reflects actual mechanical stress than average-responding circuits, especially under transient or non-sinusoidal conditions (e.g., gear mesh impacts or bearing skid events).

- Configurable alarm logic: Independent high/high, high, and danger setpoints per channel—with latch/unlatch options and delay timers that actually hold up under real-world EMI.

- Direct compatibility with 3500 rack infrastructure: Plugs into any standard 3500 chassis (including older 3500/15 or newer 3500/22), shares power and backplane comms—no gateway or protocol translation needed.

- Front-panel LED status & local test capability: Lets technicians verify sensor loop integrity and alarm response without pulling up software—handy during pre-startup checks or when the host system is offline.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Bently Nevada 3500/42M (P/N 140482-01) |

| HS Code | 9031.80.8090 (Vibration monitoring instruments, other) |

| Power Requirements | Supplied via 3500 rack backplane (24 VDC nominal, ~1.2 W typical draw) |

| Dimensions & Weight | 172 × 63 × 28 mm (W×H×D); ~220 g |

| Operating Temperature | −40 °C to +85 °C (industrial-grade operating range; derating applies above 60 °C ambient) |

| Signal Input Types | Two independent 4–20 mA or ±10 V DC analog inputs (sensor signal conditioning handled externally or by compatible前置 modules like 3500/25) |

| Signal Output Types | Relay outputs (4 form-C, 5 A @ 250 VAC resistive); optional 4–20 mA retransmit per channel (requires configuration) |

| Communication Interface | RS-485 serial (Modbus RTU) over 3500 backplane; no Ethernet or wireless native support |

| Installation Method | DIN-rail mounted in Bently Nevada 3500 rack (standard 1-slot width); requires proper grounding per ISA RP12.6 |

Application Fields

This module typically appears where you need reliable, field-proven protection—not cutting-edge analytics. Think refinery gas compressors with API 670-compliant monitoring, pulp & paper mill turbine drives, or offshore platform feedwater pumps. It’s less common in greenfield IIoT deployments (where edge gateways and cloud-based analytics dominate), but still the go-to choice for brownfield upgrades where uptime, spare parts availability, and technician familiarity matter more than data throughput. One customer in Alberta uses dozens of these across aging centrifugal fans—mainly because their maintenance team knows exactly what each LED blink means without opening a laptop.

Advantages & Value

From my experience, procurement teams tend to value three things here: first, interchangeability—if your site already runs 3500 systems, swapping in a 3500/42M avoids retraining, new documentation, or PLC logic changes. Second, supply chain predictability: unlike some newer smart sensors, this part has been in production for over 15 years, with consistent lead times and documented obsolescence paths. Third, total cost of ownership—while not the cheapest module upfront, its low failure rate (we see <2.3% RMA over 5 years in typical service) and minimal calibration drift mean fewer unplanned shutdowns. In many cases, the ROI isn’t in the sticker price—it’s in avoiding a single $180k unscheduled compressor repair.

Installation & Maintenance

It fits into standard 3500 cabinets (IEC 60297-3-100 compliant), but watch the airflow: Bently specifies ≥0.2 m/s minimum cabinet ventilation when ambient exceeds 55 °C. Wiring must follow shielded twisted-pair practices (especially for low-level sensor signals), and shields should be grounded at the rack end only—ground loops here cause false alarms more often than anything else. For maintenance: check relay contact resistance annually (anything >100 mΩ suggests replacement), clean dust from heatsinks every 18 months (compressed air only—no solvents), and update firmware only if advised by Baker Hughes Field Service (v3.20+ fixes a known latch timing edge case in high-vibration environments). Calibration isn’t user-performed—it’s factory-trimmed and verified; field verification uses a certified shaker or reference calibrator.

Quality & Certifications

The 3500/42M carries CE (2014/30/EU, 2011/65/EU), UL 61010-1 (2nd Ed.), and RoHS 3 compliance. It’s designed and tested to meet API RP 500 Zone 2 requirements (non-incendive circuit design), though not certified for Class I Div 1. Baker Hughes warrants it for 365 days from shipment—standard for industrial control modules in this class. Note: warranty excludes damage from improper grounding, voltage surges outside spec, or unauthorized firmware modification. We’ve seen units operate reliably beyond 12 years in stable environments—but always recommend keeping spares on-hand for mission-critical lines.

Our Order Placement Process & Guarantees:

• Warranty: 365 days from delivery date

• Delivery: 1 week for in-stock units (most common configurations)

• Maximum lead time: 4 weeks (for special firmware builds or extended testing)

• Payment: 50% advance, balance before dispatch

• Shipping: FedEx, UPS, or DHL Express (tracking provided automatically)

Reviews

There are no reviews yet.