Description

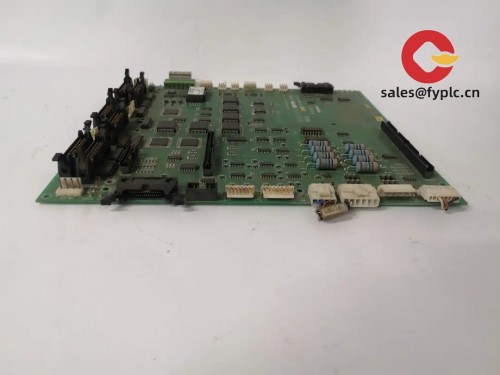

Bently Nevada 3500/45-01 (CN) Position Monitor – Four-channel axial and rod position protection for critical machinery

The Bently Nevada 3500/45-01 (often written as 350045-01-CN) is a four-channel Position Monitor used in the 3500 rack to measure and protect axial position, rod position (rod drop), and similar proximity-based displacement measurements. From my experience, plants choose it when they need reliable API 670 style protection and clean data into System 1 without re-engineering the whole panel. The “CN” suffix typically indicates a Chinese-language firmware/label set or region-specific variant, while the functional hardware remains the same as the standard 3500/45-01.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock, no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Four measurement channels – Each channel monitors position-type measurements such as axial position or rod drop with independent alarm processing.

- Proximity probe inputs – Designed for eddy-current proximity systems (e.g., Bently Nevada 3300 XL series) to measure displacement against a target.

- Alert and Danger alarms – Two alarm levels per channel with Channel OK logic for robust protection decisions.

- Buffered transducer outputs – Convenient buffered outputs for portable analyzers and validation, typically available at the module/I/O.

- Seamless 3500 rack integration – Configuration and data access through the rack TDI (e.g., 3500/22M) for System 1 connectivity and plant historians.

- API 670-style application – In many cases applied in API 670 compliant systems for rotating machinery protection and condition monitoring.

- “CN” regional variant – Typically provides Chinese UI/labels/firmware language without changing core monitoring functions.

Technical Specifications

| Brand / Model | Bently Nevada 3500/45-01 (350045-01-CN) Position Monitor |

| HS Code | 9032.90 (Automatic regulating or controlling instruments; local classification may apply) |

| Power Requirements | Powered from the 3500 rack power supply; no external power input to the module |

| Operating Temperature | Typically 0 to +65°C (per typical 3500 system environments) |

| Signal Input/Output Types | 4 proximity probe inputs; buffered transducer outputs for each channel |

| Communication Interfaces | Data/configuration via rack TDI (e.g., 3500/22M) to System 1; Modbus TCP typically through the TDI |

| Installation Method | Front monitor module + rear I/O module in the 3500 rack; panel-mounted 19″ rack systems |

| Channels | 4 channels; independent alarm processing with Channel OK |

Application Fields

You might notice that the 3500/45-01 tends to show up on high-value rotating assets where axial movement or rod behavior tells the real story. Typical examples:

- Steam and gas turbines – Axial (thrust) position protection and trending

- Reciprocating compressors – Rod position/rod drop monitoring for early wear indication

- Gearboxes and expanders – Position-based measurements in protection loops

- Large pumps and fans – Displacement monitoring where proximity probes are installed

A maintenance lead at a refinery told us they cut nuisance trips after swapping to a consistent probe/monitor pairing and tightening alarm setpoint logic on the 3500/45. That seems to be a common outcome when channel OK and buffered verification are used properly.

Advantages & Value

- Reliability in protection loops – Purpose-built alarm logic with Channel OK status helps avoid false trips while keeping protection tight.

- Compatibility – Works within existing 3500 racks and with Bently Nevada proximity systems commonly installed on rotating assets.

- Lower integration effort – Minimal rewiring; configuration through the TDI streamlines commissioning.

- Data you can act on – Buffered outputs and structured data paths to System 1 make diagnostics faster in most cases.

- Supply assurance – Clear lead times and a 365‑day warranty reduce procurement risk.

Installation & Maintenance

- Panel and cabinet – Install in a 3500 rack within a clean, ventilated control cabinet; keep ambient within the specified temperature range.

- Wiring – Use shielded coax for proximity probes; maintain proper probe gap and follow Bently Nevada proximitor grounding practices.

- I/O pairing – Match the front monitor with the correct rear I/O module; verify channel type and scaling before enabling alarms.

- Safety – Observe ESD precautions; de-energize the rack slot before inserting/removing modules when practicable.

- Routine care – Periodically verify probe gaps, review channel OK status, back up configuration, and update rack firmware via TDI when approved by site policy.

- Commissioning tip – Use buffered outputs to validate signals with a portable analyzer before setting Alert/Danger thresholds.

Quality & Certifications

- Manufacturer quality system: typically ISO 9001

- Product conformity: CE marking in most regions; UL/CSA recognition and RoHS alignment are common for 3500-series modules

- Warranty: 365 days

Note: Specific firmware language and label details for the “CN” variant may vary by build. If you’re matching an installed base, sharing your existing rack slot map and probe types usually shortens configuration time.

Reviews

There are no reviews yet.