Description

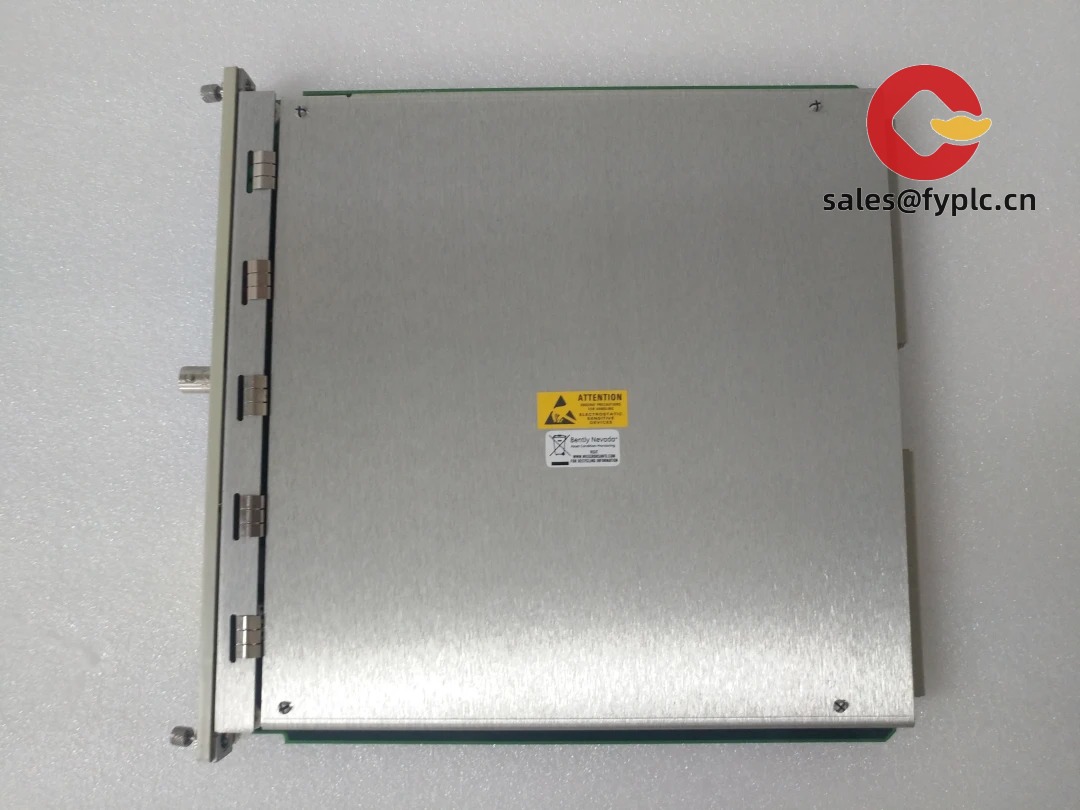

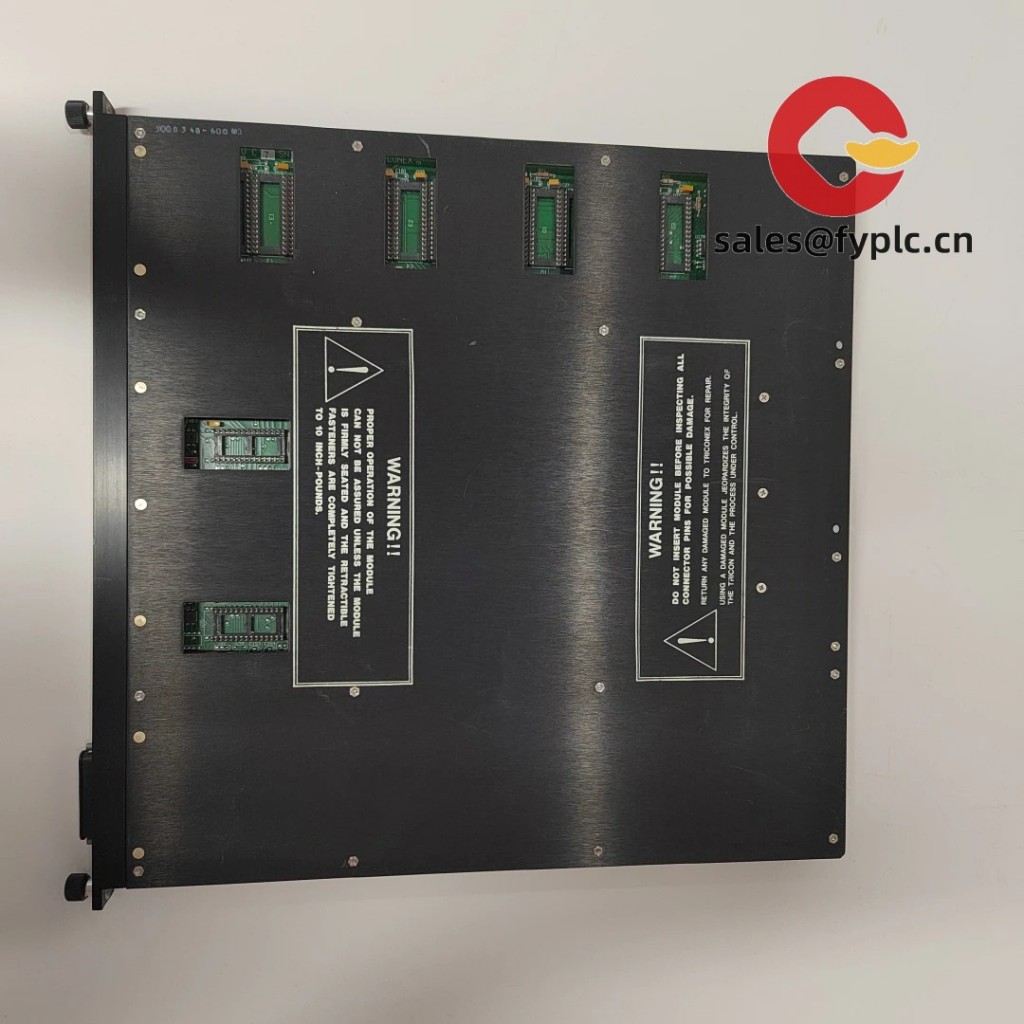

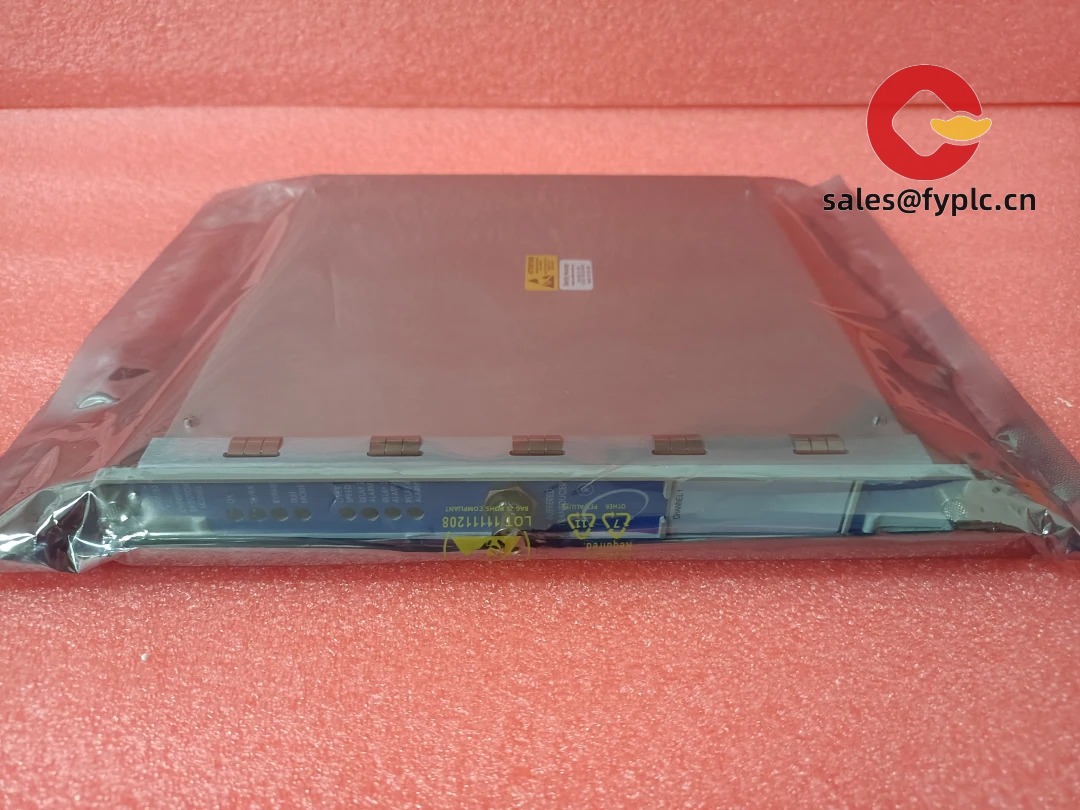

Bently Nevada 3500/53 (133388-01) – Speed/Overspeed Monitoring Module for 3500 Racks

The 3500/53 (PN: 133388-01) is a Bently Nevada rack module used for speed measurement and overspeed protection duties within the 3500 Machinery Protection System. From my experience, plants choose this card when they want deterministic speed trips based on Keyphasor‑style inputs, while keeping all protection logic inside the same 3500 framework that already handles vibration, temperature, and process variables. You might notice that it pairs with a dedicated I/O module for clean field wiring and uses the rack backplane to report status to the System 1 host via the TDI.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock, no more than one month at the latest

- Payment: 50% advance payment, full payment for delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Speed and overspeed monitoring – Uses Keyphasor/proximity or magnetic pickup signals to compute shaft speed and enforce trip limits.

- Integrated protection logic – Alert/Danger setpoints with relay actuation handled inside the 3500 rack for deterministic responses.

- Buffered tach outputs – Technicians can scope the speed signal at the I/O without interrupting protection.

- System 1 connectivity – Status and values are available over the 3500 Transient Data Interface (TDI) for trending and audit trails.

- Rack-based configuration – Consistent setup workflow alongside other 3500 modules; simplifies MOC and documentation.

- Hot‑swappable module design – Typical 3500 practice enables service with the rack powered, minimizing downtime.

Technical Specifications

| Brand / Model | Bently Nevada 3500/53, Part No. 133388-01 |

| HS Code | 9032.89 (Other automatic regulating or controlling instruments) |

| Power Requirements | Powered by the 3500 rack backplane; no external supply to the module |

| Dimensions & Weight | Standard full‑height 3500 module; occupies one rack slot (pairs with a matching I/O module) |

| Operating Temperature | Typically 0 to +65 °C (per 3500 rack environmental class) |

| Signal Input/Output Types | Speed/Keyphasor inputs (proximity or magnetic pickup); buffered tach outputs; Alert/Danger relay drive via rack |

| Communication Interfaces | Data and configuration via 3500 backplane; accessible through the 3500 TDI (Ethernet) to System 1 |

| Installation Method | Installs in a 3500 rack slot with corresponding terminal I/O module; field wiring terminates at the I/O base |

Application Fields

Typical deployments include critical and auxiliary rotating assets where speed trips matter:

- Steam and gas turbines (start-up, run-up control, and overspeed protection)

- Centrifugal compressors and expanders with speed interlocks

- High-speed pumps, blowers, and test stand spindles

- OEM skids that consolidate vibration and speed trips in a single 3500 rack

A maintenance supervisor told us they moved overspeed trips into the 3500 framework and immediately got cleaner audits — the trip events, speed values, and setpoint history sat in the same place as their vibration, which made investigations faster.

Advantages & Value

- Reliability – Proven 3500 architecture and deterministic relay behavior for safety-critical trips.

- Compatibility – Works with common Bently Nevada Keyphasor/proximity pickups and magnetic speed sensors.

- Cost Control – One rack, one tool chain; fewer gateways and less wiring than split protection systems.

- Lifecycle Support – Spares strategy is straightforward; firmware and configuration are managed alongside other rack modules.

Installation & Maintenance

- Cabinet & Ventilation – Install the rack in a clean, ventilated cabinet; allow front/rear service clearance and maintain ambient within spec.

- Wiring – Use shielded twisted pair for speed pickups; terminate shields per Bently Nevada grounding practice to avoid noise.

- Commissioning – Verify Keyphasor polarity and gap for proximity probes; validate speed scale factors and setpoints before enabling trips.

- Safety – Use inhibit/trip multiply during run-up testing; confirm relay logic, voting (if used), and permissives as part of SAT.

- Routine Care – Periodically check terminal tightness, review event logs, and back up configuration after changes.

Quality & Certifications

- Certifications: CE and UL/cUL; many 3500 builds are suitable for Class I Div 2 / ATEX/IECEx Zone 2 panels (confirm per nameplate).

- Manufacturer’s Warranty: Standard Bently Nevada policy on new units (typically 1 year, region dependent).

- Our Coverage: 365‑day warranty on supplied units as stated above.

If you’re matching an existing rack, share your slot map and sensor types. One thing I appreciate is how the 3500/53 can drop into an established protection strategy with minimal rewiring — usually it’s just validating scale factors and re‑checking relay logic to meet your trip philosophy.

Reviews

There are no reviews yet.