Description

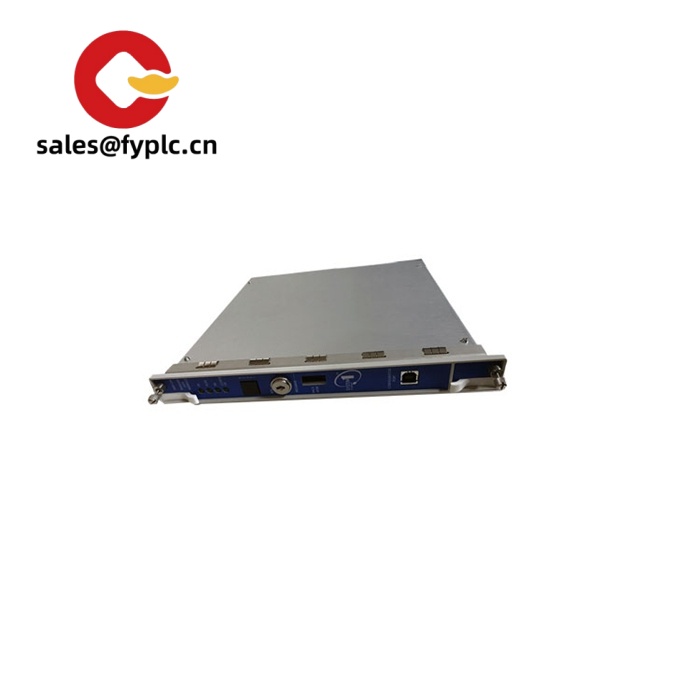

Bently Nevada 3500/62 (P/N 163179-03D) – 4–20 mA Process Variable Monitor for 3500 Machinery Protection Racks

The Bently Nevada 3500/62 is a four-channel process variable monitor designed to bring standard 4–20 mA transmitter signals (pressure, flow, temperature, level and similar process values) into the 3500 rack for alarming, trending, and machinery protection logic. Model code 3500/62 with assembly number 163179-03D integrates directly into the 3500 backplane, so you can mix process signals alongside vibration, speed, and Keyphasor measurements without adding a separate PLC or signal concentrator. From my experience, this is a straightforward way to keep all critical trip logic in one certified platform.

Company’s Order Placement Process and Guarantees

-

- – Warranty period: 365 days

-

- – Delivery time: typically 1 week for in-stock items; no more than one month at the latest

-

- – Payment: 50% advance payment; full payment prior to delivery

- – Express delivery options: FedEx, UPS, DHL

Key Features

- Four independent 4–20 mA channels – Scales and alarms standard process transmitters so operators see engineering units in the same rack as vibration.

- Rack-integrated alarming – Uses 3500 rack voting and alarm logic, and can drive system relays (via 3500/33) for shutdowns or annunciation.

- Engineering unit scaling – Simple setup to convert mA to bar, kPa, °C, L/min, etc.; you can apply ranges and filtering that match plant standards.

- Backplane communications – Data is available to the 3500/22M TDI and 3500/92 comm gateway for DCS/Historian via Modbus in many cases.

- Status LEDs and diagnostics – Per-channel OK and alarm indications make troubleshooting fast during commissioning.

- Drop-in for mixed systems – Typically used to bring seal oil pressure, lube oil temperature, or valve position into the same protection system as vibration.

Technical Specifications

| Brand / Model | Bently Nevada 3500/62 |

| Assembly P/N | 163179-03D |

| HS Code | 9032.89 (Automatic regulating or controlling instruments, other) |

| Power Requirements | Powered from 3500 rack backplane; no external power supply required for the monitor module |

| Signal Input Types | 4 channels of 4–20 mA process inputs; scaling to engineering units |

| Signal Output / Alarms | Alarms via rack; relay actuation through 3500/33; data to TDI/communication gateway |

| Communication Interfaces | Via 3500/22M TDI and/or 3500/92 Modbus gateway (rack-level Ethernet/Modbus integration) |

| Operating Temperature | Typically 0 to +65°C (module ambient within 3500 rack) |

| Installation Method | Full-height, 2-slot monitor with matching I/O module and terminal blocks; plugs into 3500 rack backplane |

| Dimensions & Weight | Standard 3500 full-height form factor (2-slot). Designed for 3500 rack card cage. |

Application Fields

You’ll typically see the 3500/62 used anywhere a protection system needs process context to make better decisions:

- Oil & Gas: Seal oil pressure, bearing header temperature, fuel gas pressure tied into trip logic for turbines and compressors.

- Power Generation: Condenser vacuum, lube oil temperature, steam pressure alongside vibration for turbines and feedwater pumps.

- Petrochemical & Refining: Reactor pressure/flow and pump suction pressure to qualify vibration alarms and prevent nuisance trips.

- Pulp & Paper, Mining: Process interlocks where process health must align with machine condition before shutdown.

One thing I appreciate is how maintenance teams can correlate a vibration spike with a drop in seal oil pressure in the same trend set. A reliability engineer at a refinery told us they cut nuisance trips by half simply by voting 3500/62 process inputs with vibration alarms.

Advantages & Value

- Reliability – Uses the same proven 3500 platform hardware and diagnostics; fewer single-purpose boxes in the panel.

- Compatibility – Works with common 4–20 mA transmitters and integrates cleanly with 3500/33 relays, 3500/22M TDI, and 3500/92 Modbus communications.

- Cost Savings – In many cases you can avoid extra analog input cards in a PLC just to get process values into the trip matrix.

- Support & Spares – Standard 3500 spares strategy; teams are already familiar with the configuration workflow.

Installation & Maintenance

- Cabinet & Rack – Mount in a standard Bently Nevada 3500 rack with adequate ventilation; keep ambient within the specified temperature range.

- Wiring – Use shielded twisted pairs for 4–20 mA loops. Terminate shields at one end to avoid ground loops. Verify loop polarity before power-up.

- I/O Pairing – Install the correct 3500/62 I/O module and terminal blocks behind the monitor. The monitor and I/O module are a matched set.

- Configuration – Set engineering unit scaling, alarm setpoints, and filtering via 3500 configuration software through the 3500/22M TDI.

- Safety – De-energize loops before landing wires. Follow plant LOTO procedures; confirm alarms and relay logic with a witnessed cause-and-effect test.

- Routine Care – Periodically simulate 4–20 mA (for example 4/12/20 mA checks) to verify scaling and alarm actions. Keep terminals clean; update rack firmware during planned outages if required.

Quality & Certifications

- CE compliant; UL/cUL recognized in typical configurations; RoHS alignment for electronic assemblies.

- Manufacturer’s warranty: typically 1 year; we supply 365-day warranty coverage as standard.

Recommended Supporting Components

- Bently Nevada 3500/22M TDI – Rack configuration and data interface over Ethernet.

- Bently Nevada 3500/33 Relay Module – Alarm and shutdown relay outputs for system voting.

- Bently Nevada 3500/92 Communication Gateway – Modbus interface to DCS/PLC/Historian.

You might notice that when these modules are combined, the 3500/62 becomes more than just an analog input—it becomes a clean way to fold process conditions into machine protection with minimal wiring changes.

Reviews

There are no reviews yet.