Description

Bently Nevada 3500/70 Expansion Monitoring Module – Real-time turbine expansion measurement and machinery protection

The Bently Nevada 3500/70 Expansion Monitoring Module is designed for critical thermal growth measurements on rotating machinery—typically steam and gas turbines where casing and differential expansion must be tracked continuously. It drops straight into a 3500 rack, ties into your existing probes/LVDTs, and provides protective alarming for trips through the system’s relay logic. From my experience, plants adopt it to avoid rubs and thrust-related failures during startup, load changes, and thermal transients, while keeping data visible to the DCS through the 3500 TDI.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Purpose-built for expansion: Monitors turbine casing expansion and differential expansion to protect against thermal rubs and thrust overloads.

- Sensor flexibility: Works with proximity probes via Proximitor systems and, in many cases, LVDT-type displacement sensors depending on the selected rear I/O.

- Integrated protection: Alarm setpoints feed the 3500 rack’s relay modules for shutdown/voting logic—no external PLC math needed for protection action.

- Rack-powered, hot-swappable design: Installs into a 3500/05 rack slot and is powered from the backplane; typically no external supply required.

- System-wide connectivity: Configuration and data access via the 3500/22M TDI, with Ethernet connectivity for DCS/PLC integration (Modbus/OPC at system level).

- Buffered outputs for diagnostics: Access transducer signals at the rear I/O, which maintenance teams appreciate for quick checks and bump tests.

- Fits mixed-measurement racks: You can run expansion alongside vibration, axial position, and speed modules in the same 3500 rack—handy for turbine trains.

Technical Specifications

| Brand / Model | Bently Nevada 3500/70 Expansion Monitoring Module |

| HS Code | 9032.89 (Automatic regulating or controlling instruments; typical classification) |

| Power Requirements | Powered via 3500 rack backplane; no separate external power supply |

| Signal Inputs | Proximity probes (eddy-current) through Proximitor systems; LVDT/linear displacement sensors supported by appropriate rear I/O module configuration |

| Signal Outputs | Buffered transducer outputs at rear I/O; alarm/status to 3500 rack for relay action and system communications |

| Communication Interfaces | Through 3500/22M TDI (Ethernet; system-level Modbus/OPC data access) |

| Installation Method | Front monitor module + dedicated rear I/O; plugs into 3500/05 rack (full-height, one rack slot) |

| Operating Temperature | Typically 0 to +65 °C (aligned with common 3500-series environmental ratings) |

| Form Factor | Standard Bently Nevada 3500 full-height plug-in module |

Application Fields

You’ll typically see the 3500/70 on large rotating assets where expansion is a trip-critical parameter:

- Steam and gas turbines (casing/differential expansion during heat-up and load changes)

- Generator trains and turbo-expanders that require tight clearance management

- Refinery and petrochemical units with frequent hot restarts or cycling duty

- Power plants upgrading from legacy 3300/3500 channels to integrated expansion protection

Maintenance feedback we’ve heard: “On hot restarts, having live differential expansion with alarm voting reduced nuisance trips and let us ramp faster without risking rubs.”

Advantages & Value

- Reliability: Proven 3500 platform with protective-grade alarming and relay logic; fewer false trips when configured with sensible voting.

- Compatibility: Works with existing Bently Nevada probes and the 3500 ecosystem (TDI, relay modules, power supplies).

- Lifecycle cost savings: Avoids thermal rub events and thrust wear; typically reduces startup delays thanks to clear expansion trends.

- Support & spares: Easy to stock and swap—hot insertion in most cases, plus familiar configuration tools for technicians.

Installation & Maintenance

- Panel/rack environment: Install in a 3500/05 rack mounted in a clean, ventilated cabinet. Keep ambient within the 3500 series rating and allow airflow around the rack.

- Wiring practices: Route transducer cables separately from power lines; shield and ground per Bently Nevada guidance to minimize noise on low-level displacement signals.

- Sensor setup: Verify probe gaps or LVDT calibration at cold condition; document zero/reference points so thermal growth trends remain meaningful.

- Alarms & voting: Set Alert/Danger limits based on OEM or site experience; use the rack’s relay voting to reduce spurious trips during warm-up.

- Routine care: Periodic buffered-output checks, connector reseat/cleaning, and configuration backups. Firmware/feature updates are handled via the 3500/22M TDI where applicable.

Quality & Certifications

- Manufactured to industrial standards; typical compliance includes CE and UL/cUL. RoHS conformity is common for 3500-series modules.

- Manufacturer’s warranty follows Bently Nevada policy; we support the unit with a 365-day warranty as stated above.

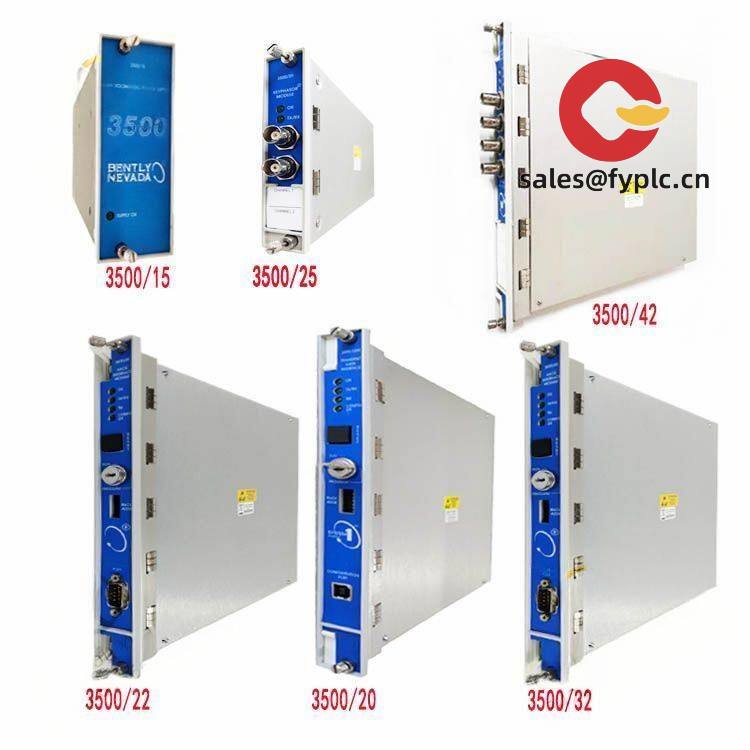

Recommended Supporting Components

- Bently Nevada 3500/05 Rack & 3500/15 Power Supply: Required platform hardware for the module.

- Bently Nevada 3500/22M TDI: System configuration and data access over Ethernet to DCS/PLC or condition monitoring software.

- Bently Nevada 3300 XL Proximity Probes / Proximitor: Common displacement sensing for differential expansion reference to the case/rotor.

- Bently Nevada 3500 Relay Modules (e.g., 3500/32M): For Alert/Danger trip action with voting logic.

From my experience, you’ll notice the biggest gains during startups and hot restarts—operators get clear trends, maintenance gets clean buffered checks, and protection stays deterministic.

Reviews

There are no reviews yet.