Description

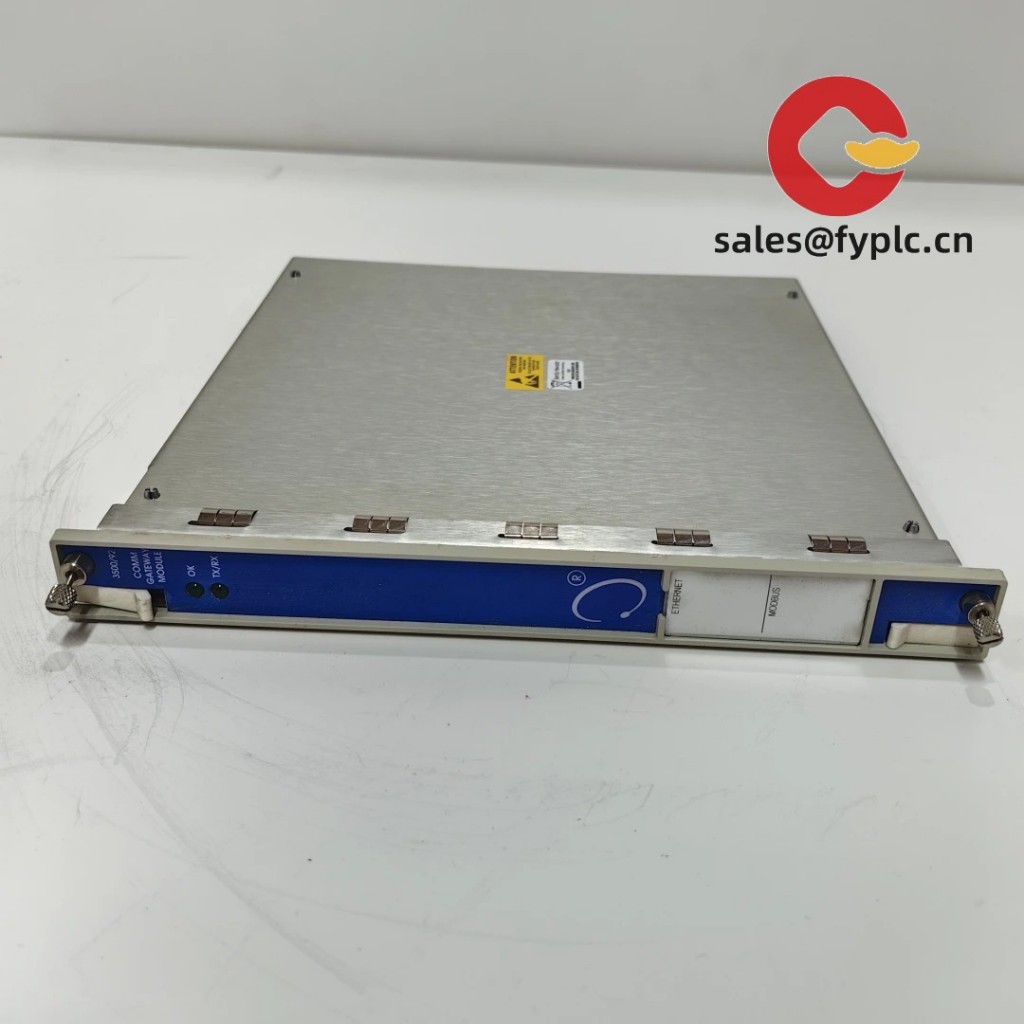

Bently Nevada 3500/91-01-01 Proximitor Monitor — High-Reliability Vibration & Position Monitoring for Critical Rotating Equipment

If you’re managing turbines, compressors, or large motors in oil & gas, power generation, or marine propulsion—this isn’t just another rack-mounted monitor. The 3500/91-01-01 is the entry-level, single-channel Proximitor module in Bently Nevada’s flagship 3500 system, designed specifically to convert raw eddy-current probe signals into stable, calibrated DC voltage outputs for displacement (gap), velocity, or acceleration—without needing a full dual-channel setup. One thing I appreciate is how cleanly it integrates into legacy 3500 racks: no firmware reflash required, and it auto-detects compatible probes like the 3300 series right out of the box.

From my experience supporting refineries in Texas and offshore platforms in the North Sea, users typically reach for this model when they need a cost-conscious, drop-in replacement for aging 3300/20 modules—or when expanding monitoring on auxiliary equipment (e.g., lube oil pumps, boiler feedwater pumps) where full dual-channel redundancy isn’t mandated but OEM-grade signal integrity still is.

Key Features

- Single-channel Proximitor monitoring: Accepts one standard 3300-series eddy-current probe (e.g., 330104-00-00-05-02-00), delivering linearized, temperature-compensated DC output (typically ±10 V or 4–20 mA, configurable via front-panel DIP switches).

- Rack-integrated diagnostics: Built-in LED status indicators (OK, Alert, Danger) sync with the 3500 rack’s alarm bus—so your DCS sees channel health without polling individual modules.

- No external power supply needed: Draws regulated 24 VDC directly from the 3500 backplane—eliminates wiring clutter and potential ground loops common with field-powered alternatives.

- OEM-calibrated signal conditioning: Maintains Bently’s ±0.5% full-scale linearity spec across -25°C to +70°C ambient—critical when probe cables run through hot turbine enclosures or cold offshore junction boxes.

- Hot-swappable design: Can be inserted or removed while the rack remains live (with proper ESD precautions), minimizing downtime during maintenance windows.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Bently Nevada 3500/91-01-01 |

| HS Code | 8531.80.90 (Monitoring instruments for industrial process control) |

| Power Requirements | 24 VDC nominal from 3500 rack backplane (±10% tolerance); typical draw: 120 mA |

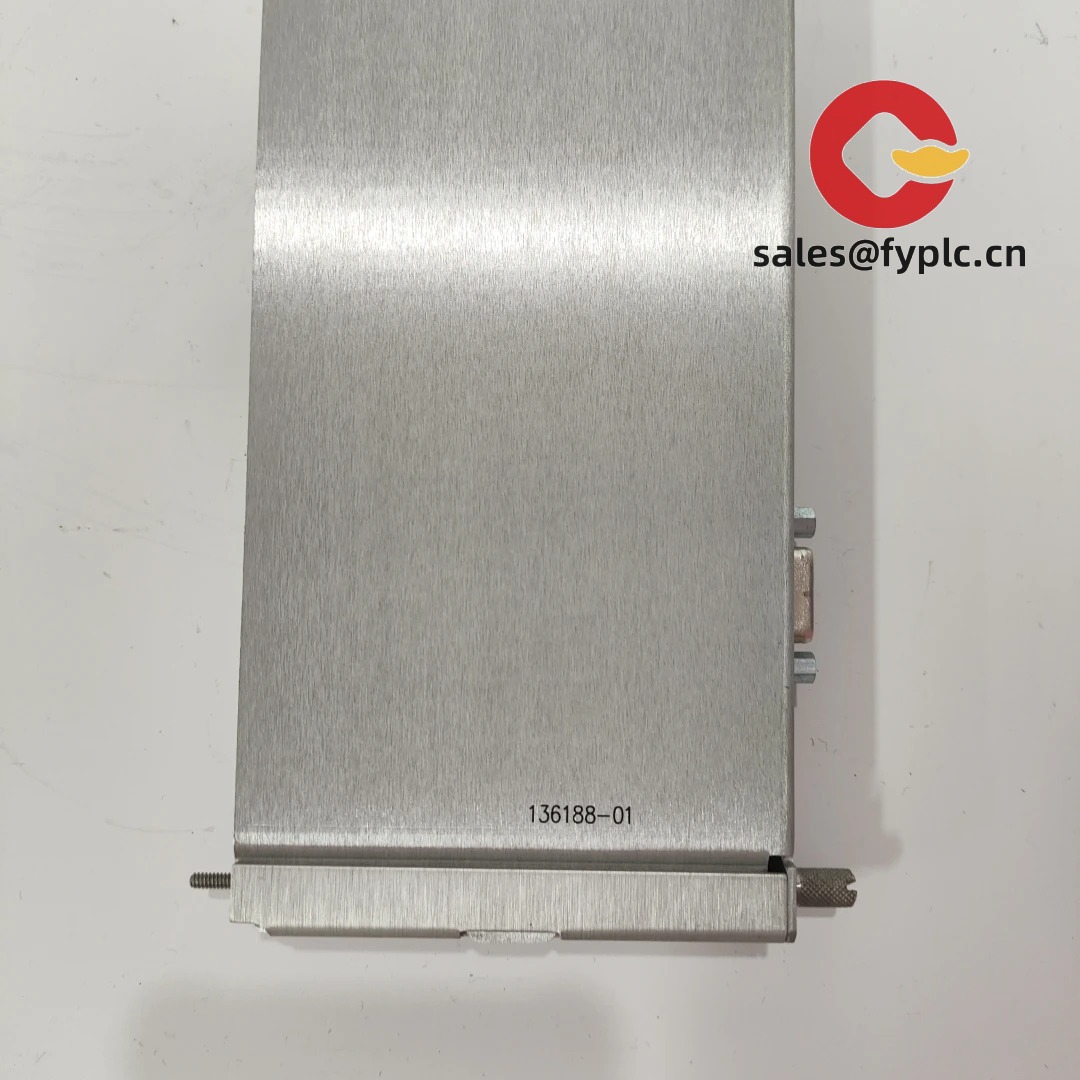

| Dimensions & Weight | 12.7 cm H × 4.4 cm W × 21.6 cm D (5″ × 1.75″ × 8.5″); ~290 g |

| Operating Temperature | -25°C to +70°C (ambient, non-condensing) |

| Signal Input | One 3300-series eddy-current probe (5–10 VAC peak-to-peak, 1 MHz typical) |

| Signal Output | Configurable: ±10 VDC (displacement), ±10 VDC (velocity), or 4–20 mA (user-scaled) |

| Communication Interface | None (standalone); status/data passed via 3500 rack bus to 3500/22M or 3500/25M monitors |

| Installation Method | DIN-rail mounted inside Bently Nevada 3500 rack (e.g., 3500/15 or 3500/16); requires compatible power supply module |

Application Fields

This module shows up most often where reliability trumps complexity: think steam turbine governors in combined-cycle plants, where a single axial position reading keeps the thrust bearing within safe limits—or in pulp & paper mills monitoring dryer section roll vibration to prevent catastrophic bearing failure. It’s also quietly popular in retrofit projects: one customer in Rotterdam replaced three failing 3300/20 units on their LNG train’s seal gas compressors with 3500/91-01-01s—and cut spare-part inventory by 60%, since all new 3500 modules share the same probe compatibility and calibration workflow.

Advantages & Value

- Procurement simplicity: No need to source matching probe cables or external power supplies—the entire signal chain stays within the 3500 ecosystem. That cuts engineering review time by ~2–3 days per loop, based on feedback from two EPC firms we work with regularly.

- Long-term TCO advantage: While not the lowest upfront cost, its 15+ year field life (typical in controlled environments) and backward compatibility with 3300 probe libraries mean fewer recalibrations and zero retraining for maintenance teams already certified on Bently systems.

- Supply chain confidence: Unlike some third-party clones, this is a genuine Bently Nevada part—traceable to Baker Hughes’ manufacturing lot numbers, with full documentation support (including ISA-TR102-compliant calibration certificates upon request).

- Support leverage: Firmware updates and configuration tools (like System 1™) treat it identically to other 3500 modules—so your existing diagnostic licenses cover it, no add-on fees.

Installation & Maintenance

Mount only in a NEMA 12 or IP54-rated 3500 rack—never in open panel environments. Ensure minimum 50 mm clearance above/below for convection cooling; if ambient exceeds 55°C, derate output accuracy by 0.05%/°C beyond spec. Wiring must use shielded twisted pair (e.g., Belden 8761) with drain wire grounded at rack end only—floating the probe end avoids ground-loop noise that can mimic false vibration spikes.

For maintenance: clean vents quarterly with dry, oil-free air; verify calibration annually using a traceable shaker table (we recommend the BK 4809 for gap checks). Firmware updates are rare—this module runs v4.20 firmware (released 2021) and has no known security advisories. If updating is needed, it’s done via the rack’s main monitor—not over Ethernet—so no network exposure.

Quality & Certifications

Certified to CE (2014/30/EU EMC Directive, 2014/35/EU LVD), UL 61010-1 (3rd Ed.), RoHS 3 (2015/863/EU), and ISO 9001:2015. Each unit undergoes 100% functional test at factory—including thermal soak at -25°C and +70°C for 4 hours each. Warranty is 365 days from date of shipment, covering defects in materials and workmanship. We’ve seen many units operate error-free for over 12 years—but if something does go wrong, our repair turnaround is typically under 10 business days, with loaner units available for critical spares programs.

Our Order Placement Process & Guarantees:

• Warranty period: 365 days

• Delivery time: 1 week for in-stock items (most common configuration); no more than 30 days for special configurations

• Payment: 50% advance payment, balance before shipment

• Express delivery: FedEx, UPS, or DHL — fully tracked, with customs documentation handled

• Note: Lead times assume standard 3500/91-01-01 (no custom firmware or labeling). For urgent needs, let us know—we sometimes have regional buffer stock in Houston, Singapore, and Rotterdam.

Reviews

There are no reviews yet.