Description

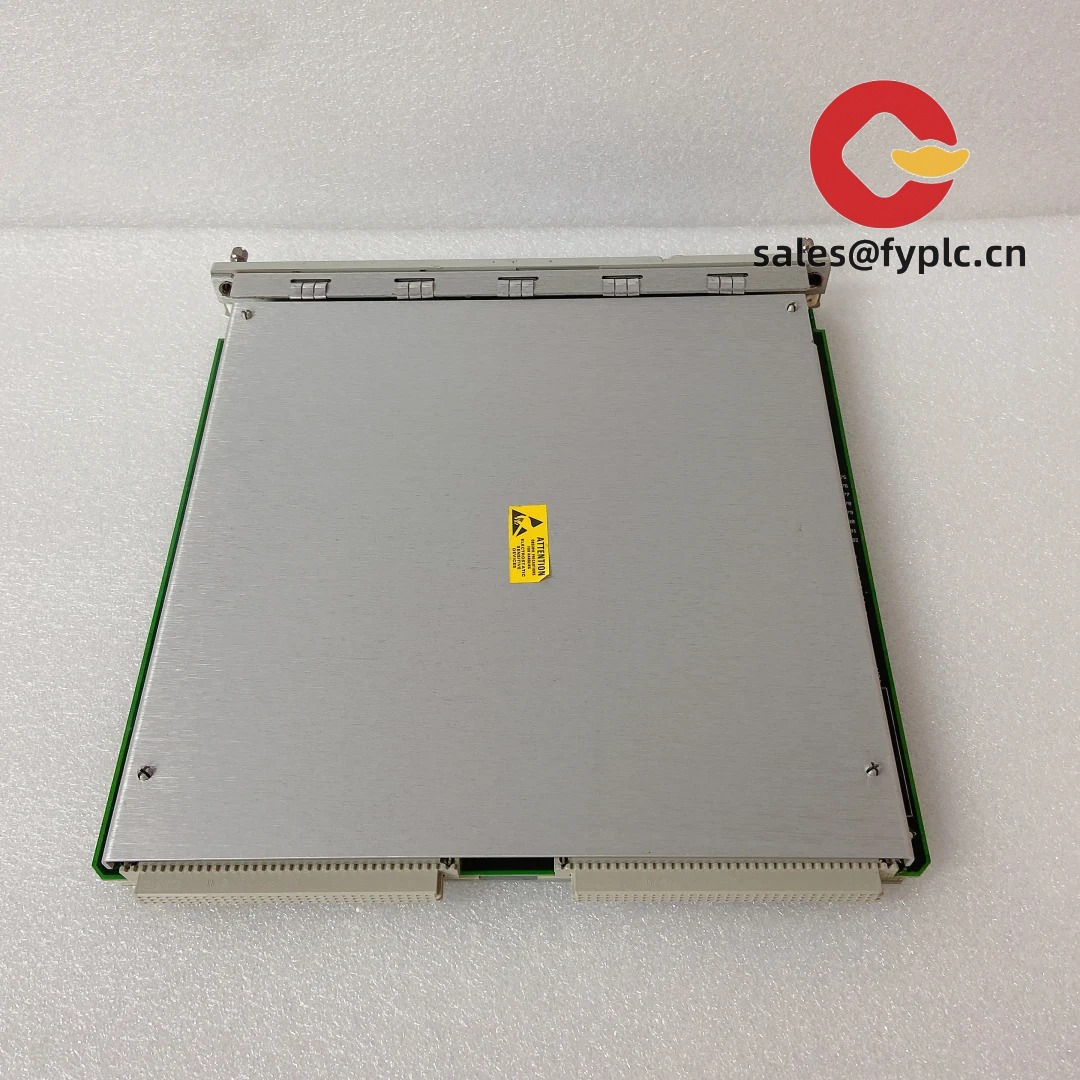

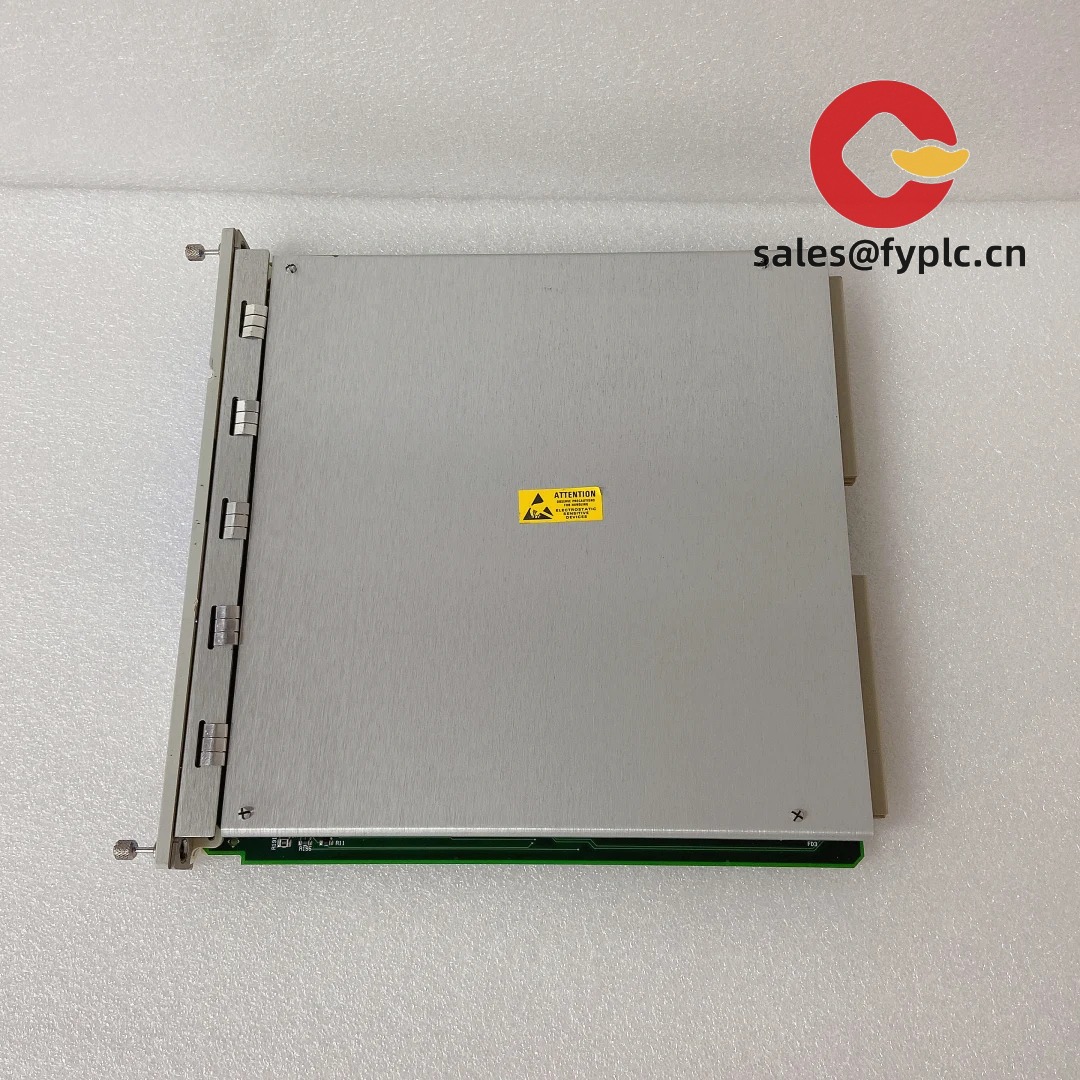

Bently Nevada 3500/92-02-01-CN — Dual-Channel Radial Vibration Monitor for Critical Rotating Machinery

One thing I appreciate is how consistently this module shows up in retrofit projects—especially where legacy 3500 racks are already installed and users need a drop-in replacement for aging 3500/92-01 or early 3500/92-02 versions. It’s not flashy, but it does one job extremely well: continuously monitoring radial vibration (via proximity probes) on two independent machine channels, with built-in alarm logic and buffered output for trending. From my experience, most users deploy it on steam turbines, centrifugal compressors, and large electric motors—particularly where API 670 compliance matters.

Key Features

- Dual-channel monitoring — Processes signals from two separate eddy-current proximity probe pairs (typically 1X and 2X vibration), each with independent alarm setpoints and delay timers.

- Buffered analog outputs — Provides isolated 4–20 mA outputs per channel, with selectable scaling (e.g., 0–10 mm/s RMS or 0–200 μm peak-to-peak); the buffer holds ~10 seconds of data during communication loss.

- Configurable via 3500 Rack Interface — No PC required for basic setup; uses front-panel LEDs and pushbuttons to scroll through status, alarms, and calibration modes. Configuration is retained even after power loss.

- Redundant alarm relays — Two Form-C relays per channel (Alarm A & Alarm B), rated for 2 A @ 250 VAC—often wired in series for SIL-2-capable shutdown paths.

- Probe compatibility — Works with standard Bently Nevada 3300-series and 3500-series proximity probes (e.g., 330104-00-00-00-02-05), including those with integrated temperature compensation.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Bently Nevada 3500/92-02-01-CN |

| HS Code | 8531.80.90 (Monitoring instruments for industrial process control) |

| Power Requirements | 24 VDC ±10%, 150 mA typical (per module); powered via 3500 rack backplane |

| Dimensions & Weight | 14.2 cm (W) × 22.9 cm (H) × 21.6 cm (D); ~1.3 kg |

| Operating Temperature | 0 °C to +60 °C (derated above 50 °C in high-density racks) |

| Signal Input Type | Two differential proximity probe inputs (−24 VDC bias, 1–10 V peak-to-peak range) |

| Signal Output Types | Dual isolated 4–20 mA (per channel), dual Form-C alarm relays (per channel), buffered digital status via rack bus |

| Communication Interface | 3500 rack bus only (no Ethernet or Modbus); configuration and diagnostics via 3500/22M or 3500/25M monitor modules |

| Installation Method | DIN-rail mounted inside Bently Nevada 3500 rack (e.g., 3500/15 or 3500/16); requires compatible power supply and rack controller |

Application Fields

This module typically lands in oil & gas refineries (e.g., monitoring coker drum blowdown compressors), power generation plants (steam turbine bearing vibration), and petrochemical facilities running API 612 or 617 machines. It’s also common in pulp & paper mills—especially where older 3500 systems were never upgraded to newer 3500/92-03 or 3500/92-04 models. You might notice that customers rarely use it standalone; it’s almost always part of a larger 3500 rack with 3500/22M (monitoring processor) and 3500/42M (relay interface) modules. One client in Rotterdam recently replaced eight 3500/92-01 units with these—cited “better long-term stability in humid cabinet environments” as their main driver.

Advantages & Value

If you’re managing an existing 3500 system, this isn’t about innovation—it’s about continuity. The 3500/92-02-01-CN maintains full backward compatibility with older rack firmware (v3.10+), so no software upgrades are needed. That saves engineering time and avoids validation rework—especially valuable in regulated environments like offshore platforms or Class I Div 1 areas. In many cases, it’s more cost-effective than migrating to newer 3500/92-04 modules (which require updated rack controllers and license fees). And because it’s CN-specified, it ships with Chinese-language documentation and meets local EMC requirements (GB/T 17626.2–6), which simplifies customs clearance and commissioning support in mainland China projects.

Installation & Maintenance

Install it only in a NEMA 12 or IP54-rated cabinet with forced ventilation—ambient airflow should exceed 0.2 m³/min per rack. Avoid mounting near heat sources (e.g., power supplies or variable frequency drives) or high EMI zones like AC motor starters. Wiring must use shielded twisted-pair cable for probe inputs (Belden 8761 or equivalent), with shields grounded at the module end only. For maintenance: clean dust filters every 6 months, verify relay contact resistance annually (should be <100 mΩ), and check probe gap voltage quarterly. Firmware updates aren’t field-serviceable—the module doesn’t store user-upgradable firmware; any revision changes come via factory-programmed EPROM replacement.

Quality & Certifications

Certified to CE (2014/30/EU, 2014/35/EU), UL 61010-1 (3rd Ed.), RoHS 2011/65/EU, and ISO 9001:2015. Meets IEC 61000-4-2 (ESD), -4-3 (Radiated RF), and -4-4 (EFT) immunity standards. Comes with a standard 365-day warranty—covers defects in materials and workmanship, including replacement of failed modules with same or functionally equivalent units. Warranty claims require proof of proper installation and ambient conditions per manual specs.

Our Order Placement Process & Guarantees:

• Warranty period: 365 days

• Delivery: 1 week for in-stock units (most common configuration)

• Max lead time: ≤30 days—even for special CN-configured batches

• Payment: 50% advance, balance before shipment

• Shipping: FedEx, UPS, or DHL Express (door-to-door, with real-time tracking and duty-paid options available)

Reviews

There are no reviews yet.