Description

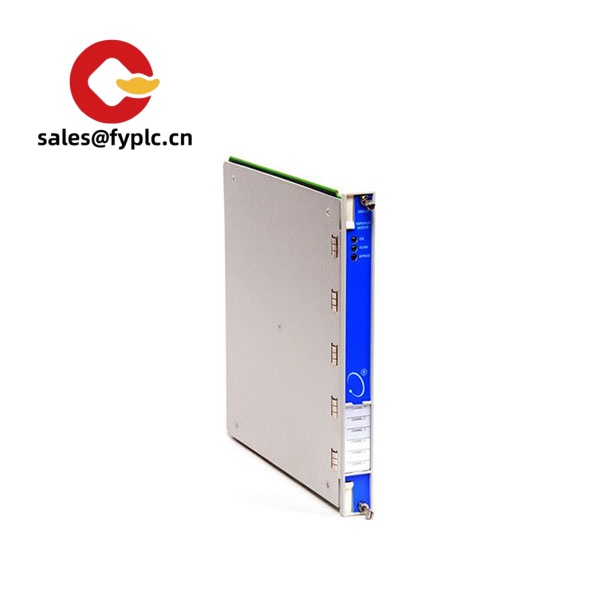

Bently Nevada 3500/92 Communication Gateway (350092-01-01-00) – Serial Modbus integration for 3500 racks

The Bently Nevada 3500/92 Communication Gateway is the bridge that lets a 3500 machinery protection rack share its status and process values with your DCS, PLC, or historian. The 350092-01-01-00 build is, in most cases, the serial Modbus version (RS‑232/RS‑485), designed to expose key 3500 measurements, alarms, and events using a widely supported protocol. From my experience, plants choose it when they want a simple, deterministic link to legacy control systems without adding another network layer.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Serial Modbus (RTU) connectivity – Typically supports RS‑232 and RS‑485, making it easy to integrate with most DCS/PLC platforms.

- Direct 3500 rack data access – Publishes vibration, process, system OK, and alarm statuses the way maintenance teams actually use them.

- Backplane‑powered module – No external power brick; the gateway draws power from the 3500 rack for a cleaner cabinet layout.

- Deterministic data exchange – Stable polling over Modbus RTU; ideal when you want predictable update timing rather than best‑effort Ethernet traffic.

- Configuration via 3500 software – You map points and set serial parameters to match the host system, which keeps commissioning straightforward.

- Industrial reliability – Designed to run in the same harsh environments where the 3500 monitoring system already thrives.

Technical Specifications

| Brand / Model | Bently Nevada 3500/92 Communication Gateway, part no. 350092-01-01-00 |

| HS Code | 903289 (Automatic regulating or controlling instruments and apparatus) |

| Power Requirements | Powered via 3500 rack backplane; no external supply required |

| Communication Interfaces | Serial Modbus RTU (RS‑232 / RS‑485) as standard for -01 builds |

| Signal I/O Types | Serial data channels; status LEDs for module and communication health |

| Operating Temperature | 0°C to +65°C (typical for 3500 rack modules) |

| Dimensions & Weight | Approx. 241 mm (H) × 25 mm (W) × 241 mm (D); ~0.6 kg (module + I/O) |

| Installation Method | Front module with matching rear I/O in a Bently Nevada 3500 rack slot |

Application Fields

You’ll typically see the 3500/92 in plants where the 3500 system protects critical rotating assets and the control system needs a clean feed of health data. Common deployments include:

- Oil & Gas – Turbomachinery vibration/status to DCS via Modbus RTU

- Petrochemical – Centralizing alarm logs and keyphasor‑derived speed in plant historians

- Power Generation – Bridging 3500 rack alarms to turbine control panels or PLCs

- Pulp & Paper / Mining – Standardized serial polling where Ethernet isn’t preferred

Advantages & Value

- Compatibility that reduces risk – Works with the installed base of Modbus‑capable DCS/PLC platforms; fewer surprises in commissioning.

- Lower integration cost – Serial wiring and polling are straightforward; you avoid additional network hardware in many cases.

- Reliable data mapping – The 3500 point database is exposed in a predictable way, which makes control logic and historian tags easier to maintain.

- Lifecycle support – Widely used across industries, so spare parts and know‑how are easier to secure over the long term.

One thing I appreciate is how consistent Modbus mapping tends to be across racks—once you’ve validated one unit, scaling to the rest of the train is usually quick. A maintenance lead recently told me their team cut over a compressor train during a short outage because “the gateway came up first time after we matched baud rate and parity—no chasing weird edge cases.”

Installation & Maintenance

- Cabinet & rack – Install in a standard Bently Nevada 3500 rack with proper bonding/earthing; provide ventilation to keep the enclosure within 0–65°C.

- Wiring – Use shielded twisted pair for RS‑485; ground one end of the shield; match baud rate, parity, and stop bits with the host system.

- Topology – For RS‑485, respect typical multi‑drop and termination practices; keep total bus length within the limits for your baud rate.

- Configuration – Set up through the 3500 configuration software; verify Modbus register maps and alarm/state bits against your control logic.

- Service – Routine visual checks for connector tightness and cable condition; periodic confirmation of communication health and firmware alignment with the rack.

Quality & Certifications

- CE compliant (typical for Bently Nevada 3500 modules)

- UL/cUL for industrial control equipment (commonly available on 3500 series)

- RoHS compliant where applicable

- Warranty: 365 days (our supply policy)

Related / Supporting Components

- Bently Nevada 3500/05 System Rack

- Bently Nevada 3500/15 Power Supply (AC or DC variants)

- Bently Nevada 3500/20 or 3500/22M System Monitor / Transient Data Interface

- Bently Nevada 3500/40M, 3500/42M, 3500/44M monitoring modules (vibration and process)

- Appropriate 3500/92 rear I/O module for RS‑232/RS‑485 wiring

You might notice that part code 350092-01-01-00 seems to indicate the serial Modbus build; if you’re targeting Ethernet/Modbus TCP, the -02 variants are typically used. If you’re not sure which option set matches your DCS, share your comms spec (baud/parity or TCP) and we’ll match the exact build and firmware to your rack.

Reviews

There are no reviews yet.