Description

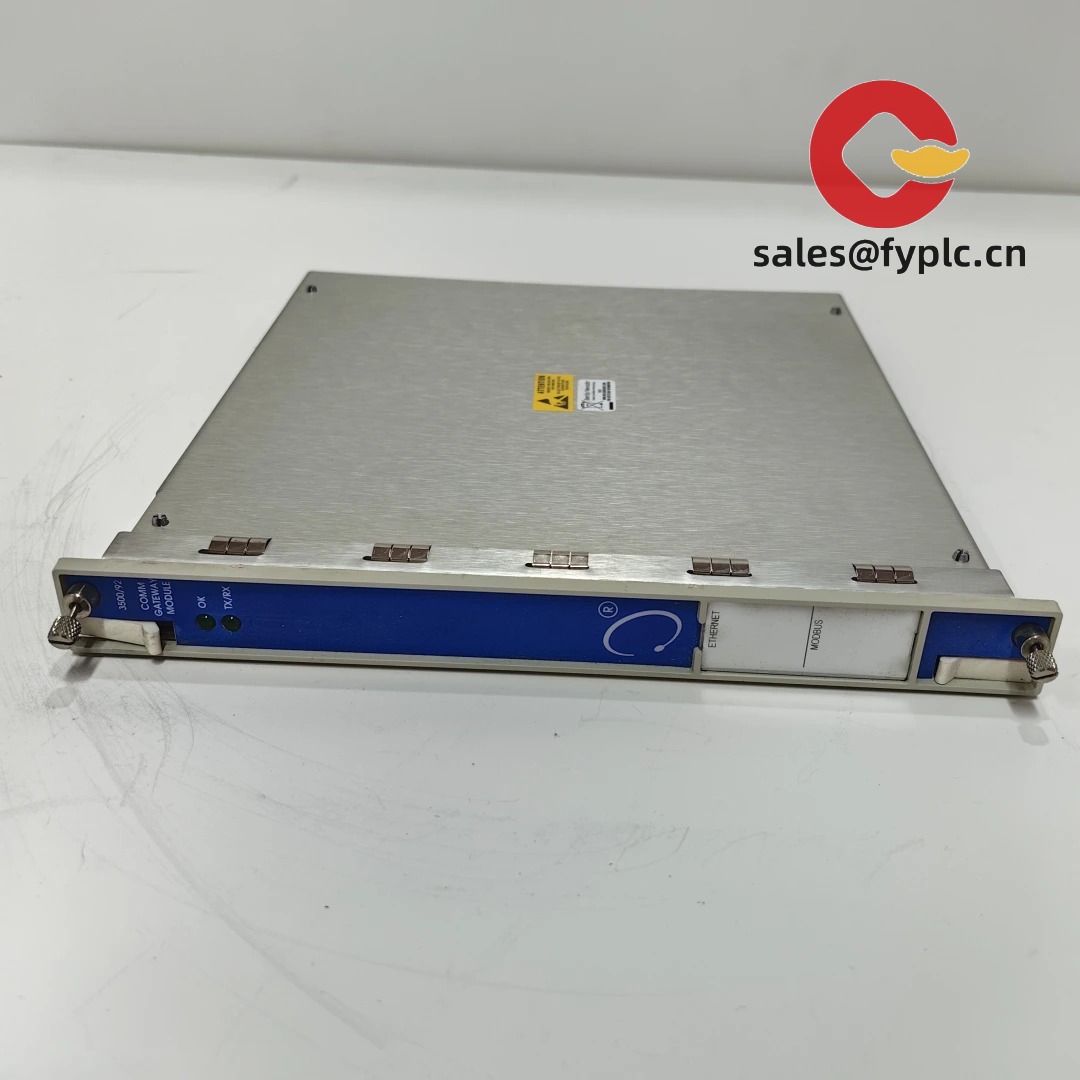

Bently Nevada 3500/92 Dual Radial Vibration Monitor (Model 133323-01)

Think of the 3500/92 as the quiet authority in your machinery protection system — not flashy, but rarely wrong. It’s the module that sits inside a Bently Nevada 3500 rack and continuously watches two independent radial vibration channels (typically from proximity probes on journal bearings), triggering alarms or shutdowns before catastrophic failure happens. From my experience supporting rotating equipment at refineries and power plants, this is the module you *don’t* want to find out is missing during a critical startup.

Key Features

- Dual-channel monitoring: Handles two independent 10–200 Hz (or optional 10–1000 Hz) radial vibration inputs — ideal for monitoring both horizontal and vertical axes on a single bearing housing.

- Configurable alarm logic: You might notice that alarm setpoints, delay timers, and latching behavior are fully field-configurable via the 3500 rack interface — no need to swap hardware for different trip philosophies.

- Redundant power input support: Accepts dual 24 VDC sources (primary + backup), which in many cases prevents nuisance trips during brief control power fluctuations — a real win during brownouts.

- Real-time status LEDs & relay outputs: Front-panel LEDs show OK, Alarm, and Danger status per channel, plus three isolated Form-C relays (Alarm 1, Alarm 2, Danger) that drive external PLCs or emergency stop circuits directly.

- Compatible with legacy 3500 systems: Works seamlessly in older 3500 racks (v10.x firmware and up), so upgrading one module doesn’t force a full system overhaul — something maintenance teams consistently appreciate.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Bently Nevada 3500/92 (133323-01) |

| HS Code | 8531.80.90 (Vibration monitoring instruments, not elsewhere specified) |

| Power Requirements | 24 VDC ±10%, 150 mA typical (dual-input capable) |

| Dimensions & Weight | 13.3 cm (W) × 22.9 cm (H) × 20.3 cm (D); ~1.1 kg |

| Operating Temperature | 0 °C to +60 °C (derated above 50 °C) |

| Signal Input Type | Two isolated -24 VDC bias, 1–9 V peak-to-peak proximity probe inputs (API 670 compliant) |

| Signal Output Types | Three Form-C relays (3 A @ 250 VAC), plus analog 4–20 mA output per channel (optional, requires configuration) |

| Communication Interface | Rack backplane only (no Ethernet or RS-485 onboard — communicates via 3500 rack’s Modbus RTU or Ethernet gateway) |

| Installation Method | DIN-rail mounted inside Bently Nevada 3500 rack (requires compatible rack slot and firmware v10.1+) |

Application Fields

This module shows up where uptime is measured in dollars-per-minute: steam turbines in combined-cycle power plants, centrifugal compressors in LNG terminals, large air-cooled condensate pumps in petrochemical facilities — anywhere API RP 670-compliant machinery protection is non-negotiable. One customer in Texas told us they’d replaced three aging 3300-series monitors with 3500/92s on their main boiler feedwater pumps — after six months, they’d avoided two unplanned outages just by catching subtle sub-synchronous vibration trends earlier than before.

Advantages & Value

If you’re evaluating replacements or spares, here’s what typically matters: First, it’s backward-compatible — no re-engineering of existing probe wiring or rack layouts. Second, the relay outputs are truly isolated and rated for industrial loads, so you’re not chasing ground loops or relay chatter. Third, spare parts availability remains strong (unlike discontinued 3300 modules), and firmware updates are still actively supported by Baker Hughes. And from a procurement standpoint? You avoid the cost and risk of retrofitting an entire new MMS platform — this fits right in, does its job quietly, and lets you focus budget on higher-impact upgrades.

Installation & Maintenance

Mount only in a clean, dry 3500 rack meeting NEMA 12 standards — avoid locations near high-current bus ducts or variable frequency drives without proper shielding. Ensure minimum 50 mm clearance above/below for convection cooling, and verify all probe cables are shielded twisted-pair with drain wire grounded *at the rack end only*. For maintenance: check relay contact resistance annually (should be < 100 mΩ), inspect front-panel LEDs during routine walkdowns, and validate calibration every 12–24 months using a certified vibration calibrator (e.g., BK 4809). Firmware updates are rare but recommended when released — they’re applied via the rack’s engineering software (System 1 or ADRE), not over-the-air.

Quality & Certifications

Certified to CE (2014/30/EU EMC Directive, 2014/35/EU LVD), UL 61010-1 (3rd Ed.), RoHS 3 compliant, and designed to meet ISO 9001:2015 manufacturing standards. Baker Hughes backs this module with a standard 365-day warranty from date of shipment — covering defects in materials and workmanship, including labor for replacement if installed per documentation. Note: Warranty does not extend to damage from improper installation, lightning surges, or use outside published environmental specs.

Our Order Placement Process & Guarantees:

- Warranty period: 365 days

- Delivery time: 1 week for in-stock units; no more than 30 days maximum

- Payment: 50% advance, balance before dispatch

- Express shipping: FedEx, UPS, or DHL — full tracking provided

Reviews

There are no reviews yet.