Description

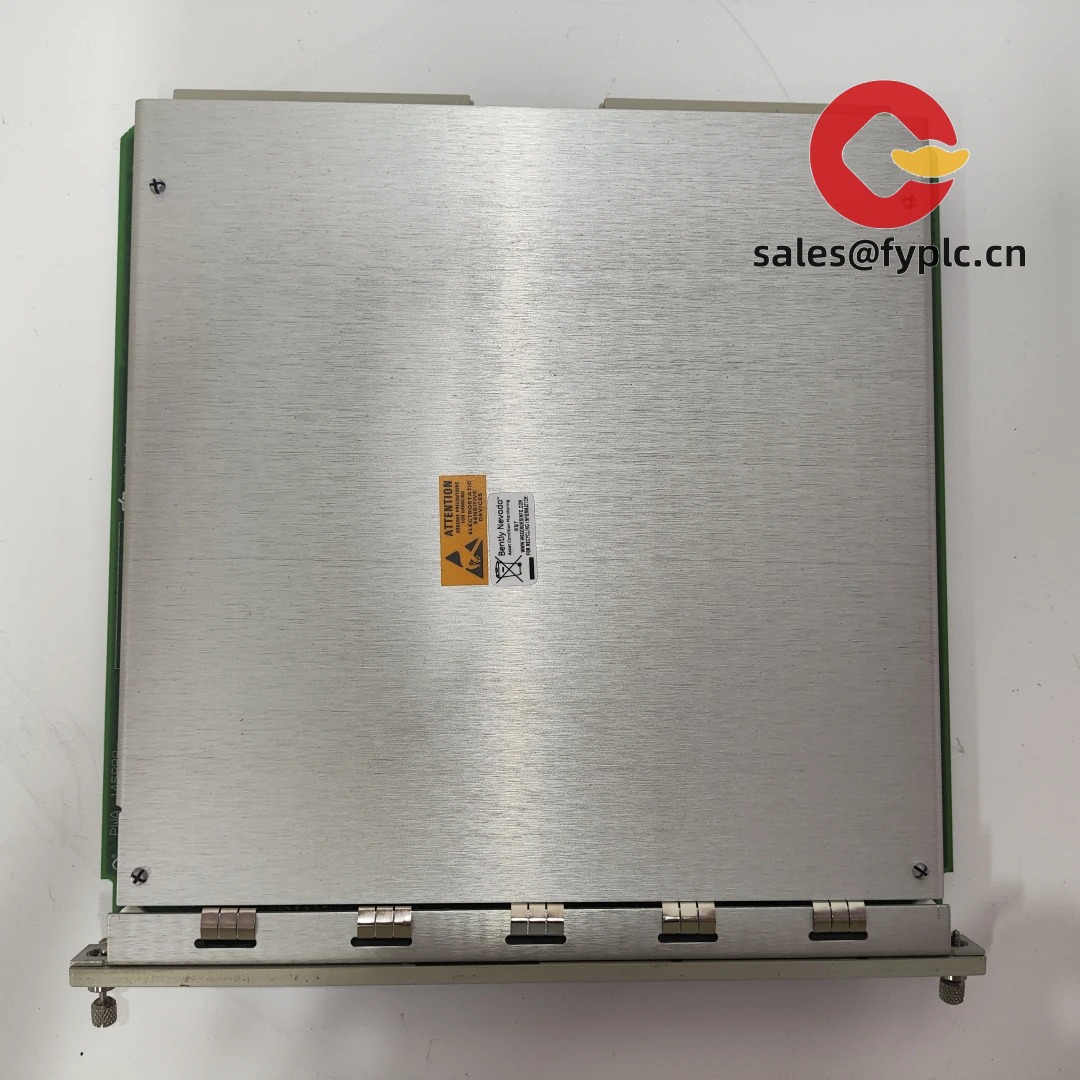

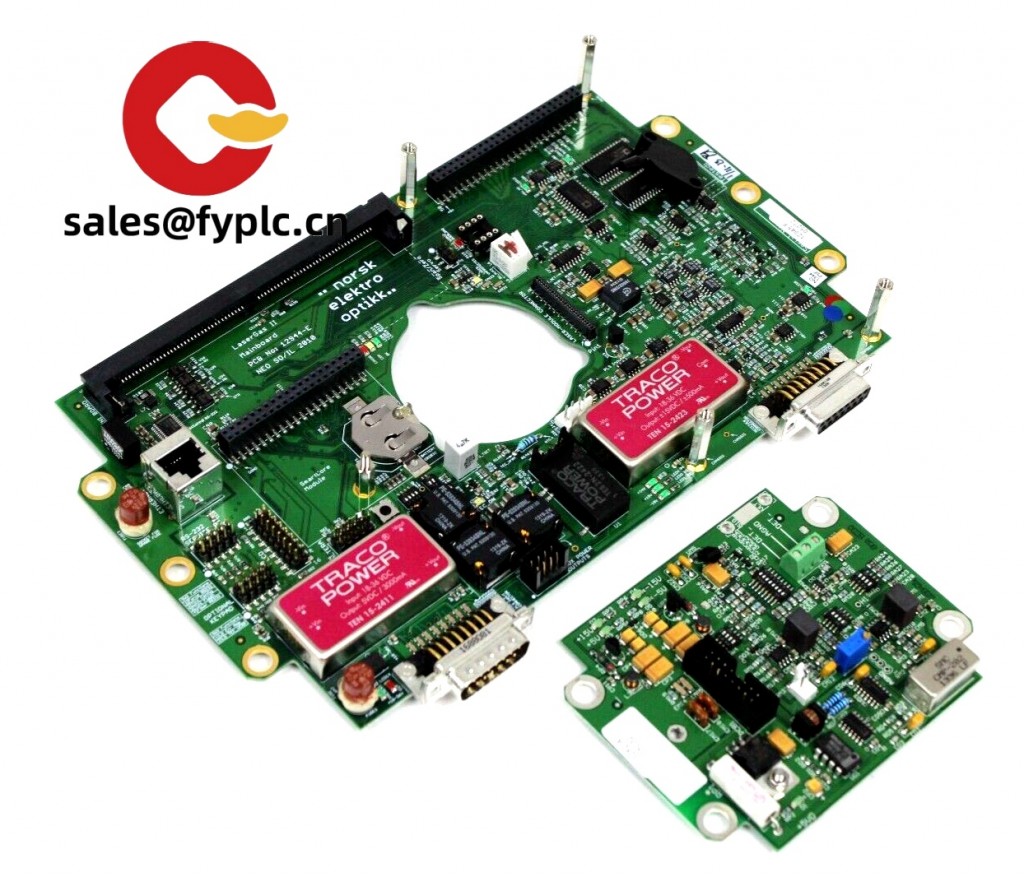

Bently Nevada 3500/94 (P/N 145988) – VGA Display Interface for 3500 Machinery Protection Systems

If you already rely on the Bently Nevada 3500 platform for critical machinery protection, the 3500/94 (part number 145988) is the straightforward way to visualize rack measurements, statuses, and alarms on a standard VGA monitor. From my experience, this module is typically selected when teams want a clear, plant-floor view of the same data the rack is using to protect turbines, compressors, and large pumps—without touching the protection logic itself.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- VGA display output – Connects to a standard VGA monitor so operators can view channel values, trends, and alarm status locally.

- Non-intrusive to protection – Reads data from the 3500 rack backplane; it doesn’t change or compromise protection functions.

- Native 3500 rack integration – Designed for the 3500 platform, typically used alongside 3500/05 racks, 3500/15 power supplies, and 3500/22M TDI modules.

- Quick status visibility – You might notice that alarm/event navigation and rack health views are much faster on a dedicated screen near the cabinet.

- Plant-ready hardware – Industrial-grade reliability that, in many cases, reduces the need to open the cabinet or connect a laptop for routine checks.

Technical Specifications

| Brand / Model | Bently Nevada 3500/94 (P/N 145988) |

| HS Code | 9031.80 (Measuring/monitoring instruments, other) |

| Power Requirements | Powered via 3500 rack backplane (through the 3500/15 power supply) |

| Communication Interfaces | VGA video output (DB-15); backplane data interface to 3500 rack |

| Signal I/O Types | Video output only; no direct transducer inputs (display interface module) |

| Installation Method | Plug-in module for Bently Nevada 3500 rack; connects an external VGA monitor at the panel |

| Recommended Companions | 3500/05 rack, 3500/15 power supply, 3500/22M TDI, 3500/93 system display (as needed) |

Application Fields

The 3500/94 is typically used anywhere a 3500 protection rack is installed and an operator-friendly visual interface is desired:

- Oil & Gas – gas turbines, centrifugal compressors, pipeline compressor stations

- Power Generation – steam and gas turbines, generator train auxiliaries

- Petrochemical & Refining – process compressors, blowers, critical pumps

- Pulp & Paper, Mining, and Metals – large rotating assets where on-skid visibility helps maintenance

A reliability engineer at a midstream facility told me they mounted a small VGA panel on the cabinet door so technicians could confirm alarm states before calling operations—seems simple, but it cut down on trips back to the control room.

Advantages & Value

- Reliability – Industrial-grade module that doesn’t interfere with protection logic; it simply mirrors rack data for visibility.

- Compatibility – Built for the 3500 ecosystem; works with common configurations using 3500/22M TDI and standard 3500 racks.

- Cost-conscious – Uses a standard VGA monitor, so you avoid specialty HMIs where a simple visual check is enough.

- Maintainability – From my experience, it streamlines troubleshooting; you can verify channel health and alarm conditions right at the skid.

Installation & Maintenance

- Panel & rack – Install the 3500/94 in the 3500 rack following standard slot and grounding practices. Ensure the cabinet meets typical industrial panel standards, with proper bonding and EMC practices.

- Ventilation – Provide adequate airflow around the rack power supply; avoid placing the monitor where heat build-up can exceed typical monitor ratings.

- Cabling – Use a quality shielded VGA cable; keep the run within typical VGA length limits to maintain signal integrity.

- Wiring discipline – Separate low-level signal and video cables from high-voltage or high-current conductors.

- Safety – De-energize the rack before inserting/removing modules when practical. If hot work is required, follow site LOTO and ESD precautions.

- Routine care – Periodically check connectors for looseness, clean dust from the module face and VGA port, and verify screen readability during preventive maintenance. Firmware alignment with your 3500/22M is recommended when updating system components.

Quality & Certifications

- Typical compliance: CE marking, UL/CSA listings, RoHS

- Manufactured under ISO 9001 quality systems

- Warranty: 365 days (our supply guarantee); OEM warranty policies may apply by region and revision

If you’re consolidating spares, the 3500/94 is a practical add-on that improves situational awareness at the cabinet. It’s a small investment compared to the time saved during commissioning and routine checks.

Reviews

There are no reviews yet.