Description

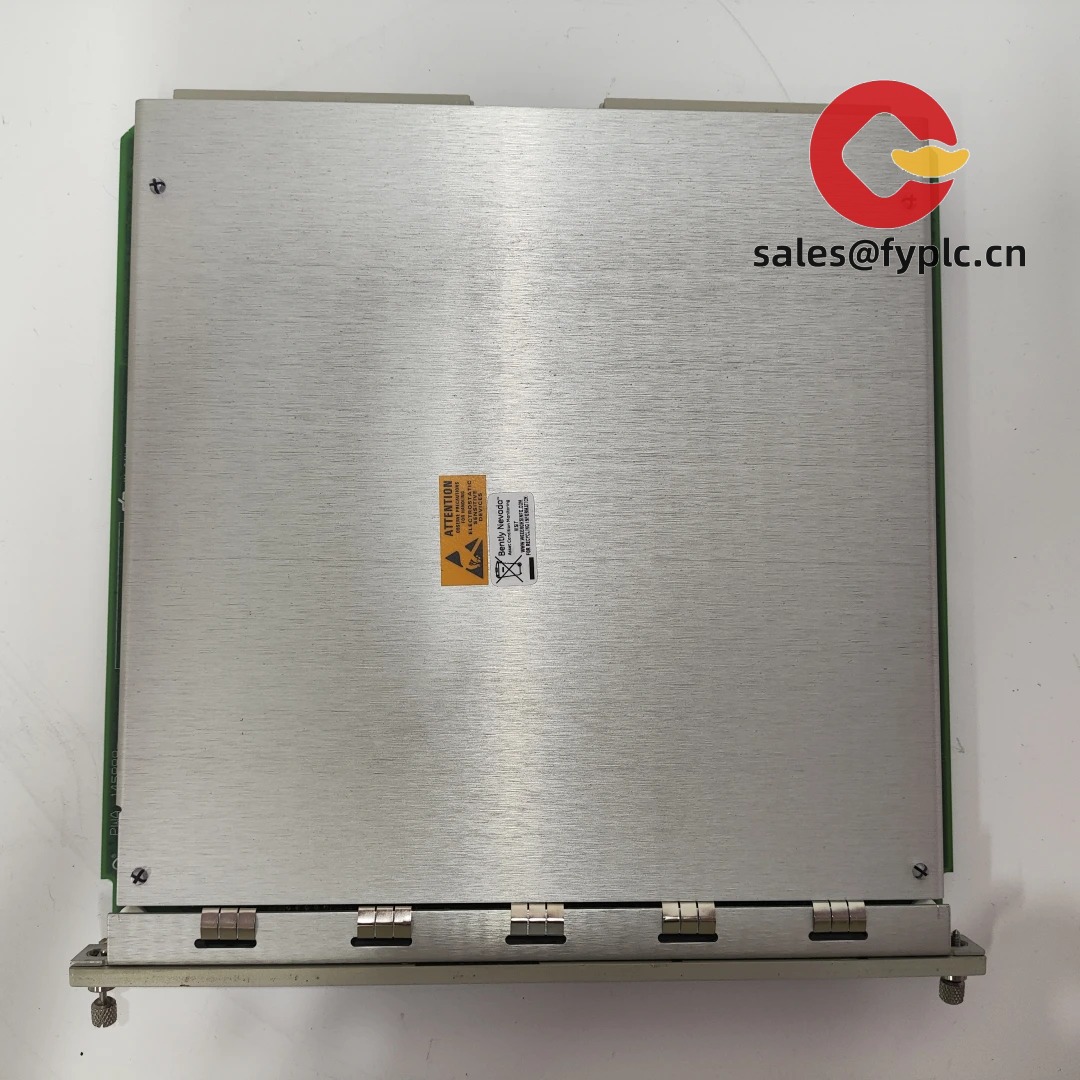

Bently Nevada 3500/94 Proximitor Monitor (Model 145988-01) — High-Integrity Vibration & Position Monitoring for Critical Rotating Equipment

One thing I appreciate is how consistently this module shows up in retrofit projects across power generation and oil & gas facilities—especially where legacy 3500 racks are still running strong but need upgraded monitoring for shaft vibration, axial position, or differential expansion. It’s not flashy, but it’s dependable: a dual-channel proximity probe monitor that handles both DC gap voltage and AC vibration signals from standard Bently Nevada 3300-series probes. From my experience, most users deploy it to protect steam turbines, compressors, or large motors where even a few seconds of undetected rub or misalignment can mean six-figure downtime.

Key Features

- Dual independent channels — Each channel supports simultaneous DC (position/gap) and AC (vibration) measurements, eliminating the need for separate modules in many configurations.

- Configurable alarm logic — Local alarm relays with programmable delay, latching/non-latching behavior, and channel voting (e.g., 2-out-of-2) — useful when integrating with existing DCS safety logic.

- Hot-swappable in live 3500 rack — You might notice that field techs rarely power down the entire rack just to replace a 3500/94; the module retains configuration during insertion, and firmware updates happen over the backplane.

- Integrated self-test & diagnostics — Continuously monitors probe bias, cable integrity, and internal supply rails; logs fault history accessible via 3500 System Monitor software.

- Compatible with standard 3300 XL probes — Works with common 5 mm and 8 mm probes (e.g., 330104-00-05-10-02-00), so there’s typically no need to re-probe machinery during upgrade.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Bently Nevada 3500/94 (145988-01) |

| HS Code | 9032.89 — Electrical apparatus for automatic control or regulation |

| Power Requirements | +24 VDC nominal (range: +18 to +32 VDC); draws ~1.2 A typical at 24 V |

| Dimensions & Weight | 175 × 42 × 260 mm (W × H × D); approx. 1.1 kg |

| Operating Temperature | 0 °C to +60 °C (derated above 50 °C for continuous operation) |

| Signal Input Types | Two channels, each accepting: DC voltage (–10 to –26 VDC bias), AC vibration (±10 V peak), or combined DC+AC (e.g., shaft position + vibration) |

| Communication Interfaces | 3500 rack backplane only (no Ethernet or RS-485); configuration & data via 3500 System Monitor (via USB-to-RS232 or 3500/22M gateway) |

| Installation Method | DIN-rail mounted in standard Bently Nevada 3500 rack (e.g., 3500/15, 3500/22M); requires rack power supply and system monitor |

Application Fields

This isn’t a general-purpose I/O module—it’s built for environments where measurement integrity directly ties to mechanical protection. In many cases, you’ll find it on:

- Steam and gas turbine monitoring (axial position, bearing vibration, thrust collar clearance)

- Centrifugal compressor trains (especially where differential expansion between casing and rotor must be tracked)

- Large motor-driven pumps in refineries—where coupling misalignment or bearing wear triggers early-stage alarms

- Retrofit projects replacing older 3300/52 or 3300/25 modules, often alongside new 3500/22M gateways for Modbus TCP integration into modern DCS systems

Advantages & Value

If you’re evaluating this for procurement, here’s what tends to matter most: First, compatibility. It drops into existing 3500 racks without rewiring probes or modifying cabinet layouts—so engineering hours stay low. Second, lifecycle cost: while newer platforms like System 1 or Machinery Health Manager offer cloud analytics, the 3500/94 still delivers deterministic, sub-millisecond response times that some OEM protection systems require. Third, spares availability: unlike discontinued models (e.g., 3500/40), this one remains actively supported by Baker Hughes—and we’ve seen lead times under 5 days for in-stock units. One customer in Texas recently told us they kept two 3500/94s as hot spares for a 20-year-old turbine train and avoided a forced outage when a channel failed during startup.

Installation & Maintenance

It fits standard 3500 cabinets (IEC 60297-3-100 compliant, 21U minimum), but watch ventilation: ambient cabinet temp should stay below 55 °C, and airflow must clear the rear heat sink fins. Wiring follows Bently Nevada’s color-coded convention (red/black for bias, yellow/green for AC)—miswiring a probe can damage the channel, so double-check before powering up. For maintenance: calibrate annually using a certified calibrator (e.g., 3500/42M test set); clean dust filters every 6 months; and update firmware only after validating against your site’s approved version list—some versions introduce subtle changes to alarm timing behavior. We’ve seen cases where unvalidated updates caused nuisance trips on high-vibration compressors.

Quality & Certifications

Manufactured by Baker Hughes (formerly Bently Nevada), this module carries CE marking per 2014/30/EU (EMC) and 2014/35/EU (LVD), UL 61010-1 certification for industrial control equipment, and RoHS 2011/65/EU compliance. It’s ISO 9001:2015 manufactured and tested per IEC 61508 SIL2 requirements for functional safety applications. Warranty is 365 days from shipment—covers defects in materials and workmanship, including replacement or repair at our facility. No restocking fees for warranted returns, and we handle cross-shipments for urgent replacements.

Our Order Placement Process & Guarantees

- Warranty: Full 365-day coverage from date of delivery

- Delivery: 1 week for in-stock units; maximum 30 days for special order or refurbished units

- Payment: 50% advance via wire transfer or irrevocable LC; balance due before release from warehouse

- Shipping: Fedex, UPS, or DHL Express — fully insured, with real-time tracking and customs documentation handled

Reviews

There are no reviews yet.