Description

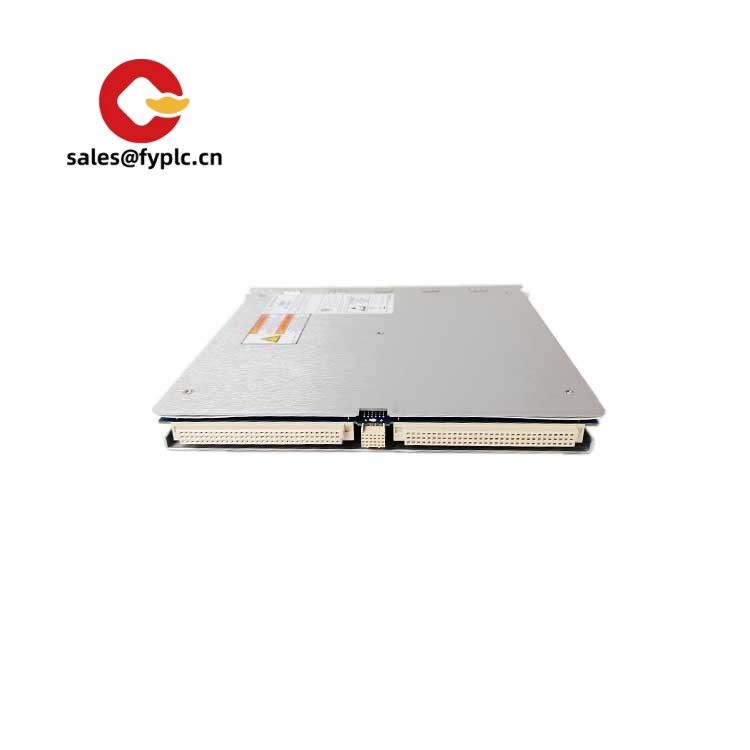

Bently Nevada 350022M_288055-01 – 3500/22M Transient Data Interface with Matching Rear I/O Plate

The 350022M_288055-01 identifies a Bently Nevada 3500/22M Transient Data Interface (TDI) supplied with its matching rear I/O plate 288055-01. From my experience, this is the “communications brain” of a 3500 rack—aggregating static and transient data from all installed monitors and serving it to your condition monitoring software (typically System 1) over Ethernet. You might notice that pairing the correct rear plate keeps cabinet wiring tidy and, in many cases, makes commissioning and later swap‑outs noticeably faster.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than 1 month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Rack communications hub – Collects static and transient data from all 3500 monitors and exposes it to plant systems.

- System 1 connectivity – Ethernet interface for condition monitoring, trending, and event capture.

- Matched rear I/O (288055-01) – Revision‑appropriate rear plate with clearly labeled terminations, which typically shortens wiring time.

- Backplane integration – Powered via the rack and synchronized across the 3500 backplane; no separate front‑end PSU wiring.

- Service‑friendly layout – Front plug‑in module and rear connectors make swap‑outs straightforward during tight outage windows.

Technical Specifications

Specs below reflect what you typically see on a 3500/22M with rear I/O 288055-01. If you share your rack option string and network settings, we’ll verify the fit before shipment.

| Brand / Model | Bently Nevada 350022M-288055-01 (3500/22M + rear I/O 288055-01) |

| HS Code | 9031.90 (Parts of measuring or checking instruments) |

| Power Requirements | Powered via 3500 rack backplane (through 3500/15 power supply) |

| Dimensions & Weight | Standard 3500 single‑slot front module with matched rear plate; rack‑mount footprint |

| Operating Temperature | Typically 0 to +65 °C when installed per 3500 rack guidelines |

| Signal Input/Output Types | Rear plate terminations for network/service; measurement data acquired internally from 3500 monitors via backplane |

| Communication Interfaces | 10/100Base‑T Ethernet to host software (e.g., System 1) |

| Installation Method | Front plug‑in to 3500/05 chassis; connect network to rear I/O 288055‑01; secure with captive screws |

Application Fields

- Compressor, turbine, and large motor trains feeding real‑time and transient data to System 1

- Balance‑of‑plant assets centralized on a 3500 rack for diagnostics and alarm visibility

- Retrofits moving from local annunciation to historian/enterprise condition monitoring

- Sites standardizing on 3500 hardware for consistent data capture and analysis across units

Advantages & Value

- Reliability – Purpose‑built TDI for the 3500 ecosystem; fewer workarounds and cleaner diagnostics.

- Compatibility – Native backplane integration; in many cases a direct, like‑for‑like replacement of an existing 22M.

- Maintenance efficiency – Clear rear terminations and status indicators help technicians move quicker.

- Risk control – A 365‑day warranty and traceable labeling support critical spares planning.

Installation & Maintenance

- Rack slotting – Place the 22M in the designated comms slot; mount the 288055‑01 rear plate firmly with captive screws.

- Networking – Connect Ethernet on the rear plate; segregate from high‑EMI cabling and verify link settings.

- Grounding – Bond rack earth per single‑point practice; maintain shield integrity on adjacent low‑level signal wiring.

- Commissioning – Confirm rack identity, IP addressing, and data collection in System 1; verify transient capture behaves as expected.

- Routine care – Check status LEDs, review comms alarms, and keep terminals tight; firmware updates when your site standard recommends.

Quality & Certifications

- CE and RoHS compliance (typical for Bently Nevada 3500 components)

- UL/cUL suitability for industrial control panels, model dependent

- Manufacturer’s warranty: 12 months from shipment

Typical field note: “Swapped the TDI and the rack was back on System 1 in minutes—transient captures looked clean.” Share your rack option string, network settings, and software version, and we’ll confirm the 350022M + 288055‑01 pairing so the changeout is smooth on the first attempt.

Reviews

There are no reviews yet.