Description

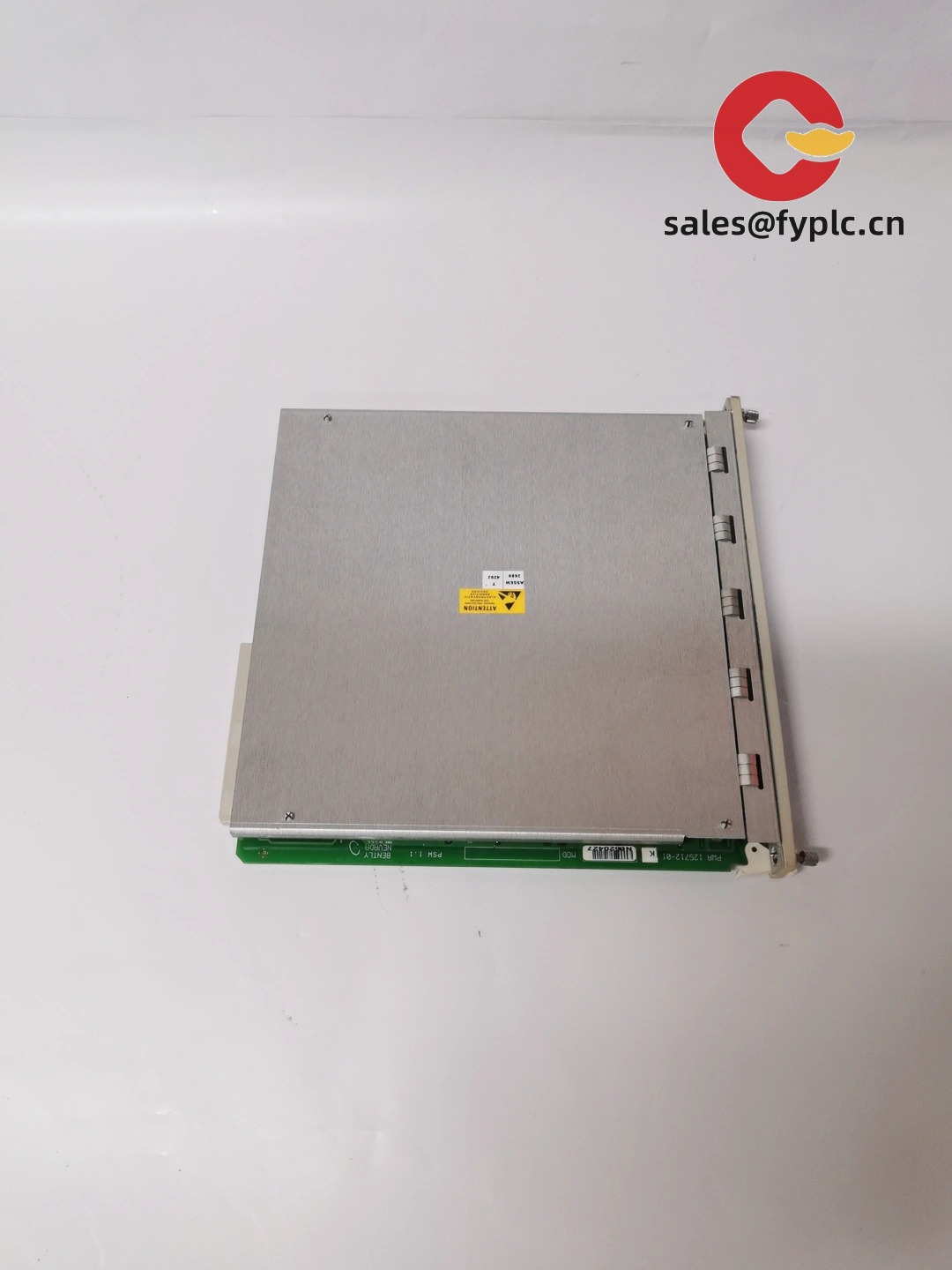

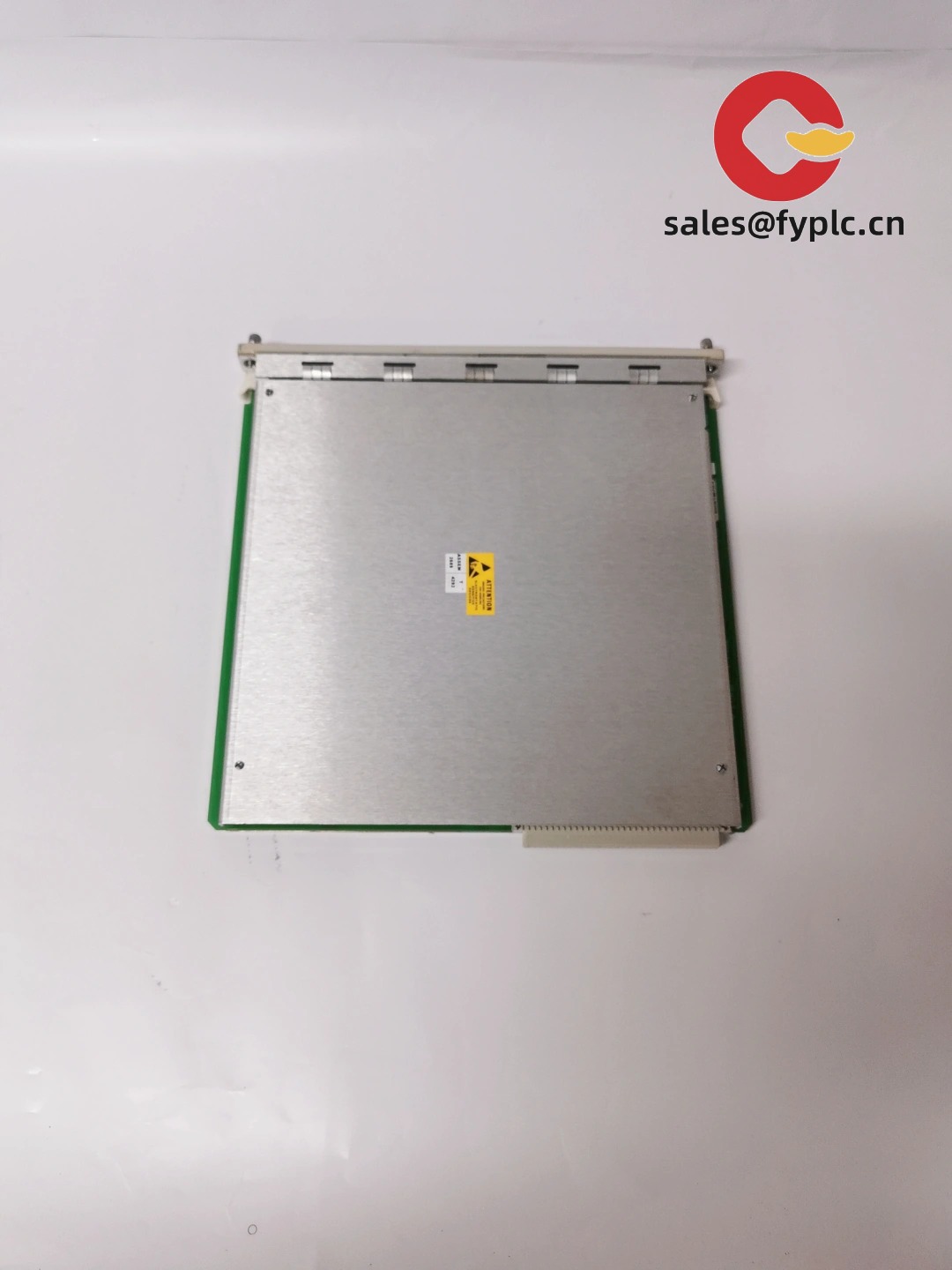

Bently Nevada 350032-125712-01 – 3500/32 Relay Module with 125712-01 Rear I/O Plate for Alarm/Trip Contacts

The 350032_125712-01 identifies a Bently Nevada 3500/32 relay module supplied with its matching rear termination plate 125712-01. From my experience, this combo is the cleanest way to bring 3500 rack alarms into your DCS, ESD, or annunciator—map channel and system events to dry contacts and keep the cabinet wiring neat on the rear plate. You might notice that sticking with the OEM rear I/O typically shortens swap-outs and avoids those “which terminal is which?” moments during loop checks.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than 1 month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Rack‑level alarm contacts – Converts 3500 monitor and system alarms into dry‑contact outputs ready for DCS/ESD wiring.

- Matched rear I/O (125712‑01) – Labeled terminals and earth points help keep field terminations tidy and traceable.

- Configurable behavior – Supports typical relay options like latching/non‑latching and N.O./N.C. contact selection in the 3500 configuration.

- Backplane powered – No separate PSU wiring; the module draws power and status from the 3500 rack.

- Service‑friendly – Front plug‑in with rear terminations means faster changeovers during tight outage windows.

Technical Specifications

Specs reflect common characteristics for a 3500/32 relay module paired with the 125712‑01 rear plate. If you share your rack option string and desired alarm mapping, we’ll verify details before shipment.

| Brand / Model | Bently Nevada 350032-125712-01 (3500/32 + rear I/O 125712‑01) |

| HS Code | 9031.90 (Parts of measuring or checking instruments) |

| Power Requirements | Powered via 3500 rack backplane (through 3500/15 power supply); no external PSU to module |

| Dimensions & Weight | Standard 3500 single‑slot front module with matched rear plate footprint |

| Operating Temperature | Typically 0 to +65 °C when installed per 3500 rack guidelines |

| Signal Input/Output Types | Dry‑contact relay outputs on rear terminals; alarm/status mapping set in the 3500 configuration |

| Communication Interfaces | Internal 3500 backplane only; no external network port on the relay module |

| Installation Method | Front plug‑in to 3500/05 chassis; land contacts on the 125712‑01 rear I/O plate |

Application Fields

- Compressor, turbine, and large motor trains where relay contacts drive trips/interlocks

- Balance‑of‑plant assets needing discrete alarm outputs to DCS or annunciators

- Retrofits that keep existing cabinet wiring while refreshing relay hardware

- Sites standardizing on 3500 racks for consistent alarm logic and maintenance practice

Advantages & Value

- Reliability – Purpose‑built relay module; fewer workarounds and cleaner diagnostics than ad‑hoc relays.

- Compatibility – Native fit in the 3500 ecosystem; in many cases a direct, like‑for‑like replacement.

- Maintainability – Rear terminals and clear legends make loop checks faster, typically reducing outage time.

- Risk control – Traceable parts and a 365‑day warranty support critical spares planning.

Installation & Maintenance

- Mounting – Seat the front module fully in the 3500/05 chassis; secure the 125712‑01 rear plate with captive screws.

- Wiring – Land relay contacts per drawings; segregate relay cabling from low‑level transducer wiring.

- Grounding – Bond the rack per single‑point practice; use the rear plate earth points to avoid loops.

- Commissioning – Verify alarm mapping and relay behavior (latching, N.O./N.C.) and function‑test in the DCS/ESD.

- Routine care – Re‑torque terminals, inspect for wear, and check module indicators during PMs.

Quality & Certifications

- CE and RoHS compliance (typical for Bently Nevada 3500 components)

- UL/cUL suitability for industrial control panels, model dependent

- Manufacturer’s warranty: 12 months from shipment

Feedback we hear often: “Wiring was straightforward on the 125712‑01 plate and relay testing passed first try.” Share your rack option string and desired alarm mapping, and we’ll confirm the 3500/32 + 125712‑01 pairing so your changeout is smooth on the first pass.

Reviews

There are no reviews yet.