Description

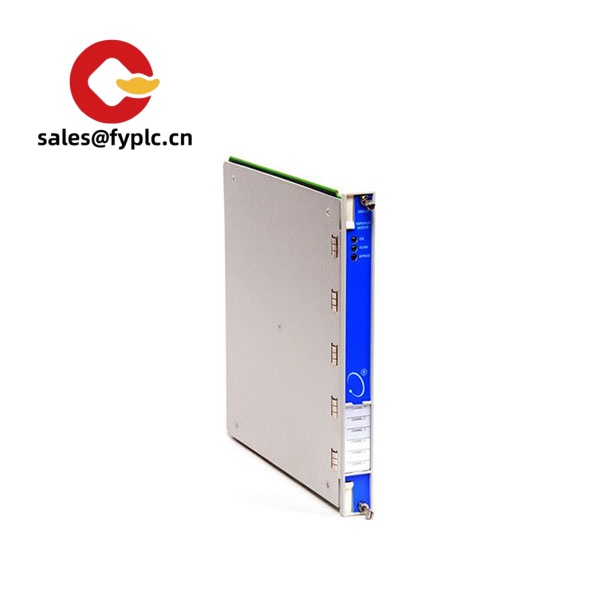

Bently Nevada 350053-03-00 – 3500 Series Rack Module for Machinery Protection and Condition Monitoring

The Bently Nevada 350053-03-00 is a 3500-series module variant (commonly aligned with the 3500/53 option set) designed to work inside a 3500 rack and extend machinery protection and condition monitoring functions. From my experience, plants typically use this style of card to expand channel coverage or system logic within existing 3500 frames without changing the rest of the architecture. It drops into the rack, mates with the corresponding I/O base, and communicates over the backplane—so integration is straightforward and downtime stays low.

Our Order Process and Guarantees

- Warranty: 365 days

- Delivery: Typically 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express Options: FedEx, UPS, DHL

Key Features

- Native 3500 rack compatibility: Installs into the Bently Nevada 3500/05 rack and works with the standard backplane and I/O bases.

- Backplane data exchange: Uses the 3500 backplane for status, alarms, and configuration handshakes; system communications are typically via the 3500/22M TDI.

- Optioned variant (-03-00): The -03-00 code denotes a specific channel/I-O option set, which, in many cases, is picked for installed-base consistency and spares commonality.

- Protection-centric design: Built for continuous, high-availability machinery protection environments—refineries, power plants, and critical rotating assets.

- I/O on terminal base: Field wiring and any buffered outputs are handled at the paired I/O module, keeping cabinet wiring neat and serviceable.

- Service-friendly: Module removal and insertion are straightforward; most teams plan swaps during controlled windows to avoid nuisance alarms.

Technical Specifications

| Brand / Model | Bently Nevada 350053-03-00 (3500 series module variant) |

| HS Code | 9032.89 (Automatic regulating or controlling instruments; final classification may vary by destination) |

| Power Requirements | Powered via 3500 rack backplane (using the 3500/15 power supply); no separate external supply |

| Dimensions & Weight | Standard 3500 rack form-factor; 2-slot module; typical module weight around 0.6 kg |

| Operating Temperature | Typically 0 to +65 °C (installation environment dependent) |

| Signal I/O Types | Field I/O and any buffered outputs are handled on the associated I/O terminal base matched to this module option (-03-00) |

| Communication Interfaces | Backplane interface to 3500 system; external system communications typically via 3500/22M TDI (e.g., Modbus/TCP, Ethernet) |

| Installation Method | Installs into 3500/05 rack slots with a matching I/O module; secure via captive screws; follow rack slotting rules |

Application Fields

You’ll typically find this module in continuous-process and heavy rotating equipment environments where availability is critical and data integrity matters.

- Refining and petrochemical units (compressors, large pumps, steam turbines)

- Power generation (gas/steam turbines, generator train auxiliaries)

- Pipeline compression and midstream rotating machinery

- Pulp & paper, steel, and cement plants needing 24/7 monitoring

One reliability engineer told me their main reason for standardizing on this variant was simple: it slotted into existing 3500 frames and kept spares common across multiple sites. That seems to be a quiet cost saver over the long haul.

Advantages & Value

- Reliability in critical service: Built for high uptime and stable protection logic in harsh industrial environments.

- Seamless compatibility: Works natively with 3500/05 racks, 3500/15 power supplies, and 3500/22M TDI—no surprises during commissioning.

- Lifecycle cost control: Common spares strategy and minimal re-engineering when adding channels or replacing modules.

- Supportable configuration:</-strong> From my experience, maintenance teams appreciate the consistent 3500 workflow and diagnostics.

Installation & Maintenance

- Cabinet & rack: Install in a 3500/05 rack mounted in a ventilated control cabinet; maintain clear airflow around the rack.

- Wiring: Land field wiring on the matched I/O terminal base; keep sensor and power wiring segregated to reduce noise pickup.

- Power & safety: Isolate power when adding or removing modules where possible; follow your site’s lockout-tagout procedures.

- Commissioning checks: Verify rack slotting, OK status, and channel configuration; confirm alarms and relays behave as intended.

- Routine care: Periodic visual inspection, terminal re-torque checks, and dust removal; back up configuration and, when applicable, keep firmware and TDI software current.

Quality & Certifications

- Manufactured to industry standards for machinery protection systems

- Commonly supplied with CE compliance; UL and RoHS conformity may apply depending on region and build

- Manufacturer warranty support processes align with typical Bently Nevada service practices

Compatible and Supporting Components

- Bently Nevada 3500/05 – System rack

- Bently Nevada 3500/15 – Power supply (AC or DC options)

- Bently Nevada 3500/22M TDI – Transient Data Interface for system communications (e.g., Modbus/TCP)

- Bently Nevada 3500 I/O terminal bases – Field wiring and buffered outputs matched to the module option

- Bently Nevada 3300 XL/330500 series sensors – Proximity probes, accelerometers, and associated probes commonly used with 3500 systems

If you’re matching the exact -03-00 option to an installed rack, share your current slot map or a photo of the rack faceplate. You might notice small differences in I/O terminal part numbers across sites; confirming those upfront typically prevents any commissioning delays.

Reviews

There are no reviews yet.